Содержание R1K 34

Страница 6: ......

Страница 62: ......

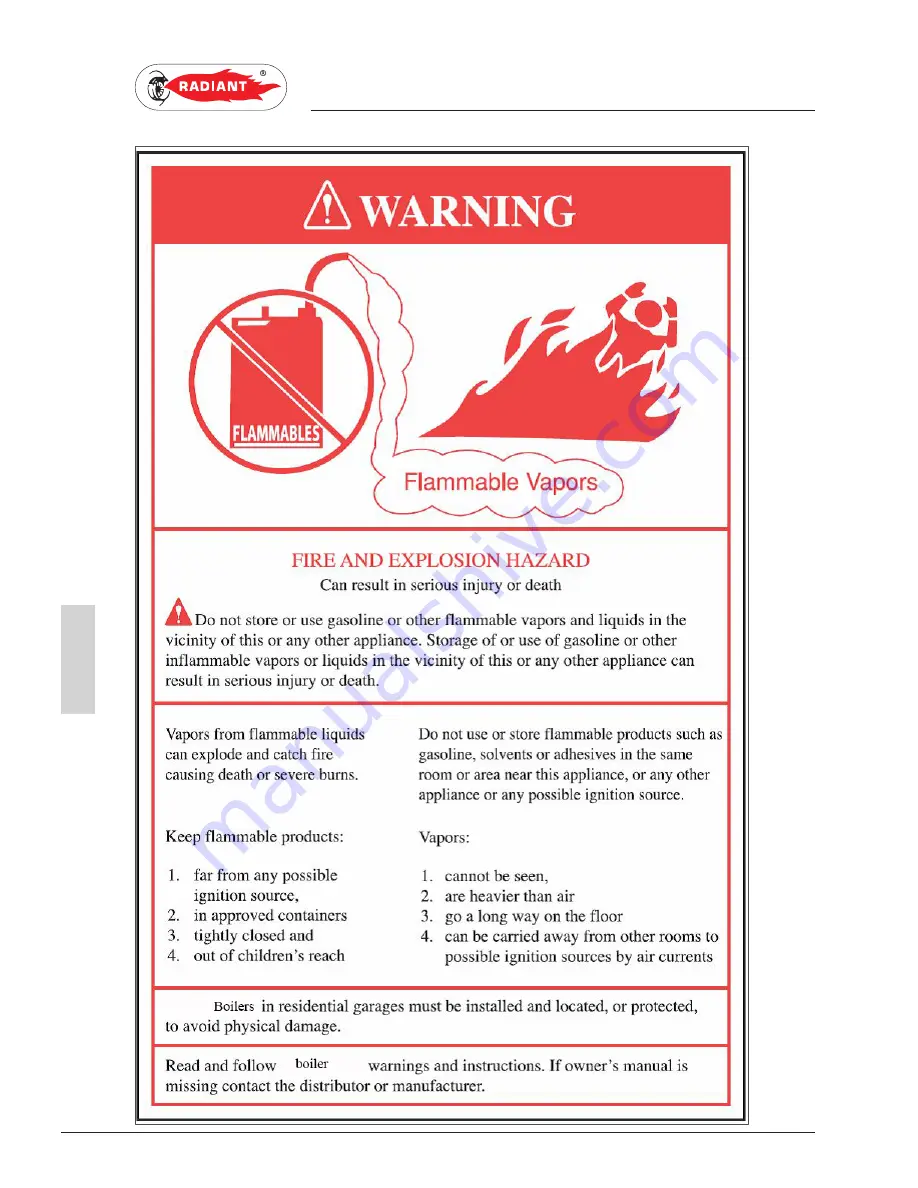

Страница 65: ...65 R1K 34 B RAD ING Manuale 1512 2_CSA_TTS 3 USE USER...

Страница 66: ...66 R1K 34 B RAD ING Manuale 1512 2_CSA_TTS 3 USE USER...

Страница 67: ...67 R1K 34 B RAD ING Manuale 1512 2_CSA_TTS 3 USE USER...

Страница 68: ...68 R1K 34 B RAD ING Manuale 1512 2_CSA_TTS 3 USE USER...

Страница 79: ......