910212- Battery Powered Rail Drill

racinerailroad.com

racinerailroad.co.uk

6.2023 Rev.1

Original Instructions

© 2023 Racine Railroad Products

Page

17

of

21

Section 4: Maintenance

It is highly recommended to practice regular check-ups and maintenance in accordance

with the usage frequency to keep your tool in better condition and reduces total running

costs.

1. After the job is done, clean the drill and keep in a clean place.

Anti-rust oil can be applied to the surface

.

2. Use a new drill bit when the old drill is worn out or damaged

。

3. Turn OFF the battery and removed it from the drill when doing maintenance or repair.

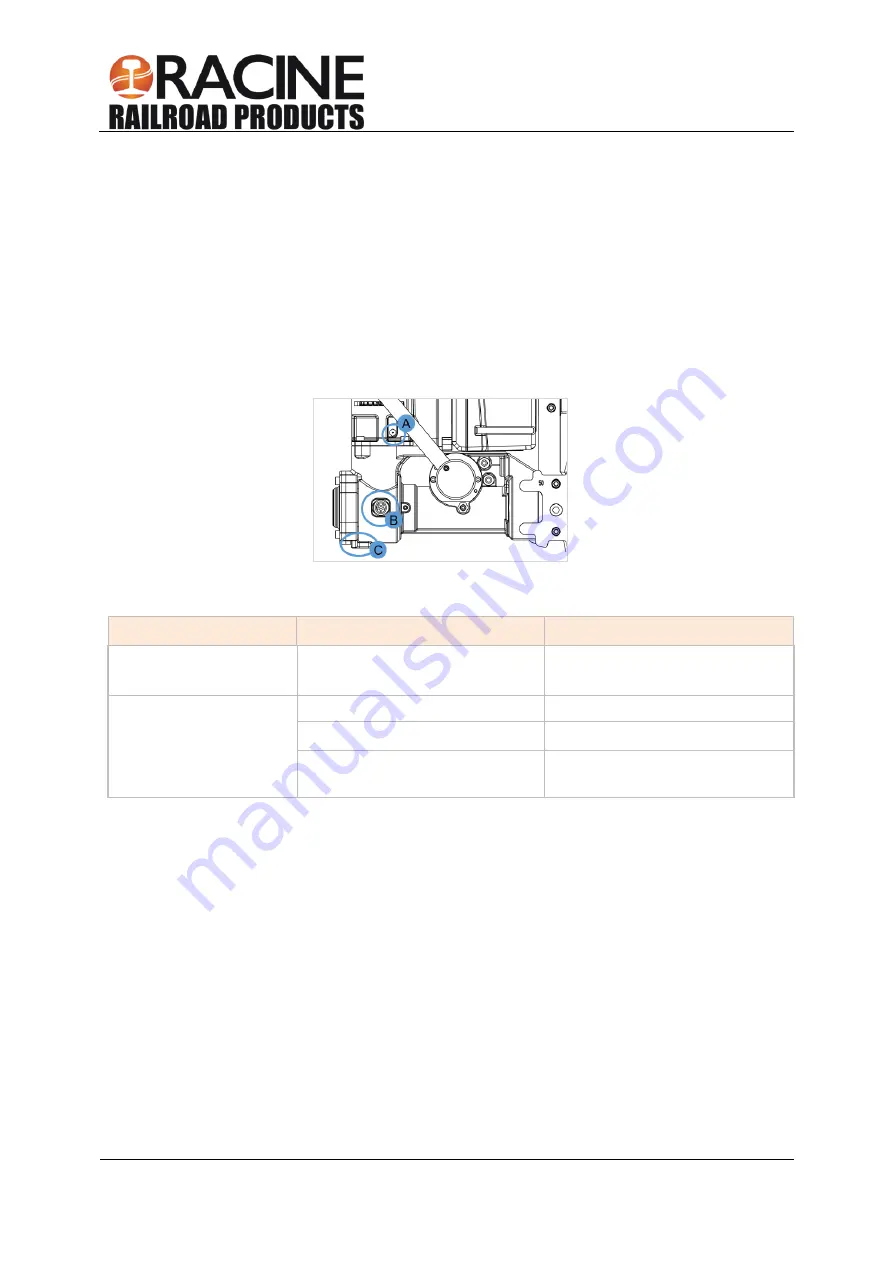

4. Use a grease gun to add grease to the grease (FT-3004) hole every six months.

5. Add oil (75W-90) to the oil injection hole.

A. Grease Hole

B. Oil Injection Hole

C. Oil Spill Hole

Troubleshooting

Problem

Possible Cause

Resolution

The motor does not start

properly

The battery is out of charge

Recharge the battery

Drill bit damage

Overload

Put drill force evenly

A damaged drill bit was used

Change to a new drill bit

The drill is not clamped

properly

Adjust and reset up the drill

Storage

1. If not being used for an extended period of time, remove the socket from the machine

and stored it separately.

2. Apply anti-rust oil on the surface of the machine and keep it in a ventilated, dry,

corrosive, gas-free environment.

3. After the job is completed, remove the battery from the machine and store separately.

4. Charge the battery with 50% ~ 80% of the power and stored in a dry and cool

environment (refrigeration conditions are more effective).

5. Charged the battery every 2 months to help to avoid irreversible battery capacity loss

due to self-discharge and long term storage.