32

b. Select a load resistance of 2 ohms. Switch to a 20A meter. Vary the Gain to display a small

amount of ordinary voltage clipping (indicated by the presence of ripple at peaks of the output

signal). Note: Check that the red clip LED is working.

c. Adjust the current limit trimpots (T2 & T3) until the amp begins current limiting (ripple and

amplitude of peaks flatten) and then back off the pot slightly to the point where the amp just

shows full ripple.

d. Check the short circuit current (2.5 to 4.5 amps).

7. Crossover (bias) adjustment

a. Select an 8-ohm load.

b. Change the input frequency to 20kHz and decrease the input level to 20dB. Adjust the

crossover trimpot, T1, for 3 CM peak-to-peak of crossover spike protruding from the noise

signal on channel B of the oscilloscope. Note: The bias shouldn’t need adjusting unless the

amp is over-heating or the drivers have been changed.

8. 20kHz

distortion

a. Select a 4-ohm output load.

b. Check that the distortion is no greater than 0.1% at all output levels from –20dB (1.5 watts) to

full output (at least 150W x 2).

9. 4 ohm power output and frequency response

a. Switch the distortion analyzer to volts/power. Select a 2kHz signal input to the amplifier.

b. Adjust the input signal to obtain 140 watts (x2) or –9.5dB output and observe power output at

20Hz (-0.5dB max.), and 20kHz (-0.5dB max.).

10. Temperature cycle

a. Switch to the 2-ohm load. Increase the signal to the point of clipping and short the output of the

amplifier. The clip LED should be on. Check for recovery into 2 ohms (cold).

b. Check the IC rails (5 to 7VDC &

±

1VDC).

c. After 1 to 3 minutes the Temp LED should start flashing and 2 to 3 minutes later the

signal/mute relay should go off and the power/protect LED should turn red. Check (with

temperature probe) the turn-off temperature at the PTC. This temperature should be 100

°

C,

±

5

°

C. Using a 5A meter, check that the idle current is not more than 0.8 amps and that it

decreases to less than 0.6 amps as the amplifier cools.

d. Cool the heatsink with a fan, (or less preferably, with freeze spray) and observe the short circuit

current limited operation (3.0 – 5.5A) into the shorted output (hot). Test the amplifier recovery

from a short into a 2-ohm load.

e. Set the load resistance to 8 ohms. Decrease the input signal and check for presence of a step

glitch at 65W,

±

10W.

11. Final Check

a. With the load resistance at 8 ohms, see that distortion does no exceed 0.1% at 20kHz from

200W to 2W (-20dB).

b. For the signal to noise test, adjust the output for 200W (-8dB). Remove the input signal and

measure the noise level. The residual noise level must be no more than 5mV on the

oscilloscope.

c. Reduce the Variac voltage. Observe the relay dropout at about 20VAC (

±

10V).

Содержание III Series

Страница 1: ...Series III Power Amplifiers TECHNICAL SERVICE MANUAL 3800 R E V B TD 300001 AX 3500 3350 3200...

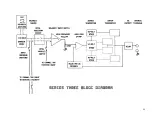

Страница 3: ...3 SERIES THREE POWER AMPLIFIERS...

Страница 22: ...22...

Страница 37: ...Series Three Schematics Model3200...

Страница 38: ...Model 3350...

Страница 39: ...Model 3500 Early Version...

Страница 40: ...Model 3500 Late Version...

Страница 41: ...Model 3800...

Страница 42: ...Series Three PCB Drawings Model 3200 PCB...

Страница 43: ...Model 3350 PCB...

Страница 44: ...Model 3800 46A PCB...

Страница 45: ...Model 3800 47A PCB...

Страница 46: ...Model 3800 48B PCB...

Страница 47: ...Model 3800 Gain PCB...

Страница 48: ...QSC Audio Products Inc 1675 Mac Arthur Blvd Costa Mesa CA 92626 Tel 714 754 6175 Fax 714 754 6173...