7

Calibration

7.1

Fluorescent Polymer Calibration (Two-Point with Zero)

1. Rinse the main module sample cell three times with DI water. Fill the sample cell with DI water.

*

NOTE

*

In emergency, “non-Fluorescent Polymer” water, such as city water, may be

used, but re-calibrate using DI water for the zero step as soon as it is available.

2. Power on the SP-380P by pressing

. Allow 5–10 seconds for the SP-380P to stabilize.

3. The unit is actively reading and displaying both Fluorescent Polymer and PTSA. The values will be very

low if DI water is used; Fluorescent Polymer value should be near zero. A low non-zero value (e.g.

0.1 or 0.2, etc.) is not problematic.

4. Press

F-Cal

(

) to launch the

CALIBRATION

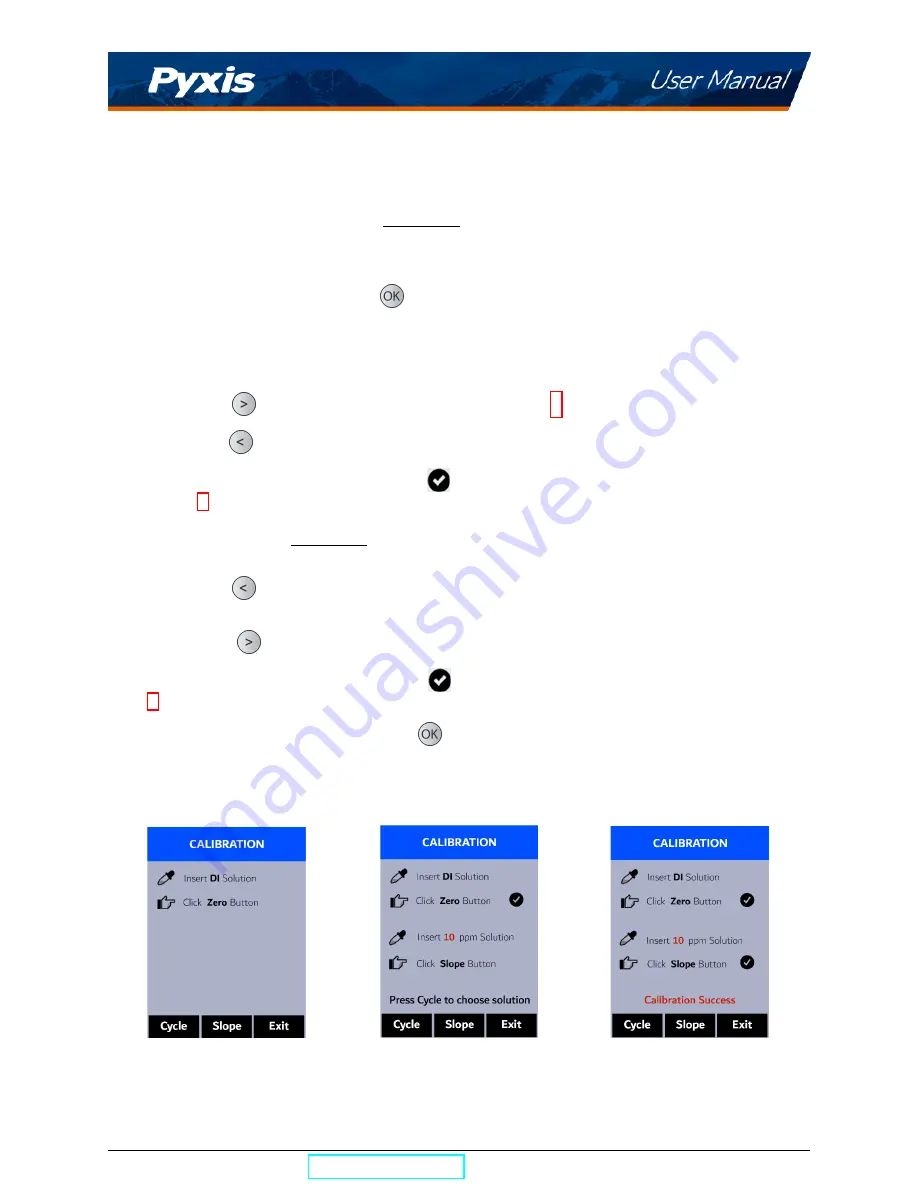

screen (Figure 3).

5. Press

Zero

(

) to start the zero (blank) calibration.

6. If the calibration succeeds, a checkmark (

) and instructions for the slope calibration will appear

(Figure 4).

7. Rinse the sample cell three times with the desired Fluorescent Polymer standard. Fill the sample cell

with the desired Fluorescent Polymer standard.

8. Press

Cycle

(

) to cycle between the Fluorescent Polymer standards 10 and 20 (it repeats). Ensure

the value selected matches the desired Fluorescent Polymer standard in the sample cell.

9. Press

Slope

(

) to start the slope calibration.

10. If the calibration succeeds, a checkmark (

), a ”

Calibration Success

” message will appear (Figure

5). Otherwise, a warning message is displayed.

11. Calibration is now complete. Press

Exit

(

) to return to measurement mode.

*

NOTE

*

If

Exit

is pressed before the second checkmark appears, the calibration will

not be completed and must be re-done.

Figure 3.

Figure 4.

Figure 5.

SP-380P User Manual

| +1 (866) 203-8397

6

Содержание 50402

Страница 1: ......