DURAWATT

®

ELECTRIC WATER HEATER

PV500-6 09/07

5

SERVICE CLEARANCES

Allow sufficient space to provide adequate clearances on all sides for service and inspection. Recommended clearance is

24” at the top and front, 18” at left and right sides of the appliance. Optional equipment may increase the clearance

requirements. Allow sufficient space for installing and servicing connections such as water, electrical, pump and other

auxiliary equipment.

CLEARANCES TO COMBUSTIBLE SURFACES

The appliance must not be installed on a combustible floor, or on a non-combustible floor covering combustible material.

Clearance to unprotected combustible material must be 6” minimum at top, sides and rear, and 24” minimum in front.

Recommended access for service is 18” at sides and rear and 42” in front.

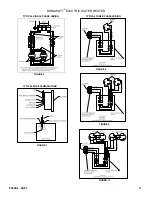

ELECTRICAL CONNECTIONS

Check rating plate on front for correct voltage, phase and amperage. Refer to wiring diagram for control components

mounted on heater.

Use proper wire size and branch circuit protection as required by National Electrical Code and state and local codes. The

PVI electric water heater specification sheets show number and size of power connectors furnished with the heater for

minimum 90°C copper connecting wire.

Use correct size ground wire, attach to pressure connector provided and marked with decal “GR.”

Connect supply feeders to distribution block (or circuit interrupter if furnished) inside electrical enclosure on the heater

IMPORTANT:

Check all wiring connections in heater and element enclosure to assure tightness prior to energizing.

NOTE: Use only copper wire of proper sizing for incoming service. Damage resulting from use of aluminum

wiring is excluded from coverage under the warranty of this unit.

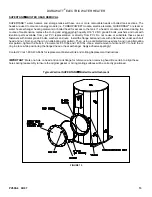

ELECTRONIC LOW WATER CUTOFF

The device consists of a probe in the tank that acts as a switch, closed when submerged in water and open when the

water level is below the probe, preventing heating elements from energizing. The probe should be kept free of scale

buildup to insure operation.

OPTIONAL EQUIPMENT

Shunt Trip Circuit Interrupter

(optional on all models): The shunt trip, wired in the non-automatic circuit interrupter, is a

safety device designed to open the circuit interrupter and prevent the elements from energizing if the control panel door is

opened.

Time Sequencer

(optional on all models):

Time sequencing is optional and used in lieu of the proportional sequencer. It is a series of time delay relays wired to the

contactors which allows approximately a 40 second delay in energizing each succeeding heating element when the

controls call for heat. This prevents all heating elements from energizing at the same time.

Proportional Sequencer

(optional on all models): Progressive sequencing (orbital) equalizes the on time for each

contactor and heating element. The heating elements are staged-on based on the demand on the water heater. The

control gives visual, indication of stages that are on. In the event of power interruption, all contactors are turned off. When

power is resumed, the control will re-stage the elements beginning with number one.