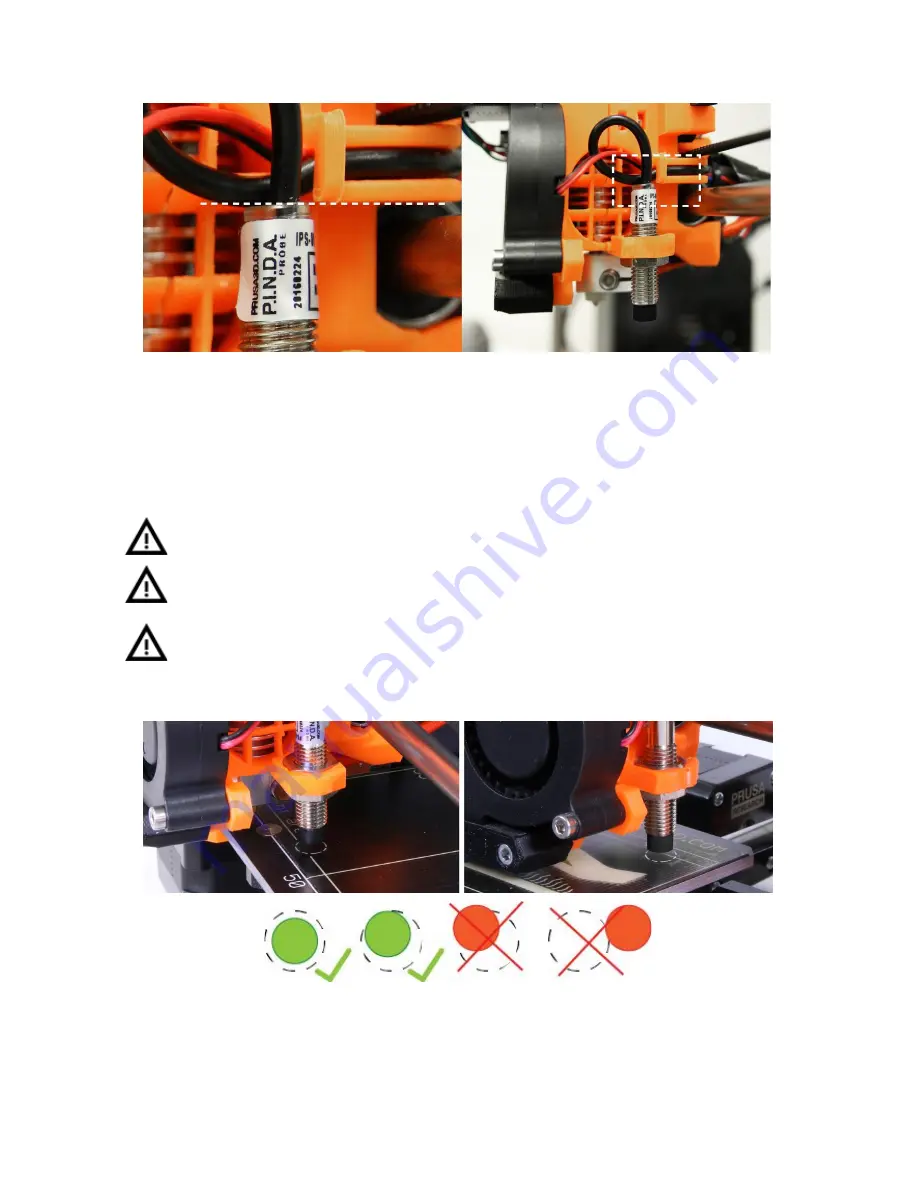

Pic. 6 The top of the probe should be aligned with the bottom of a printed part

When you run the

Calibrate Z

feature from the

Settings

menu on the LCD panel, the printer

will run the calibration routine. Closely watch how the probe approaches the 9 calibration

points. 1st and the last points are marked with white dashed circles for easy recognition. The

probe must be inside those circles to successfully calibrate.

The nozzle must not touch the print surface during this cold

calibration.

If it bends the print surface OR the probe is not

inside the circles, it is wrong and you have to readjust the

P.I.N.D.A probe!

Only then you should continue with the calibration

process. If you’re having trouble, feel free to ask us for help. If the

problem is not taken care of during the cold calibration, the nozzle

will

permanently damage

the print surface when hot.

Pic. 7 The probe must be inside the circles to successfully calibrate

.

If the probe is misaligned, you can easily adjust the position of the Y axis inside the frame by

loosening the

M10 nuts

on the Y axis and securing them at the newly adjusted position.

15