Promix-SM104

2

Check completeness of the lock set when buying! After buying, the

manufacturer will not accept claims related to incomplete set.

3.

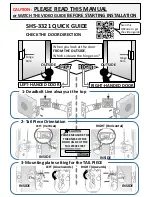

SET OF DELIVERY

4.

DESIGN AND PRINCIPLE OF OPERATION

The locks are manufactured in one version based on the normally closed (NC) principle. NC

lock is in the closed state when the latch is inserted and no voltage is supplied, and in the open

state when the lock is energized. To open the door, the lock must be energized.When opened,

the lock pushes out (shoots off) the latch, which leads to the door opening slightly. The lock

operates as well when the door is in a “tension” condition, i.e., when some external force is

applied to open the door

(see 5.2)

(e.g., someone pulls the door handle).

The locked may be equipped with a door position sensor. The built-in door position sensor

consists of a magnetically controlled sensor (sealed-contact reed relay) mounted on the lock

body, and a magnet mounted on the mobile sleeve of the lock and displaced by the latch. The

reed relay contacts open when the door is opened (the latch is withdrawn from the lock) and

close when the door is closed (the latch is inserted into the lock to a stop). The sensor is on the

back side of the lock.

5.

TECHNICAL DATA

5.1

OPERATING CONDITIONS

The lock operation environment must be explosion-safe, free of current-conducting dust or

gases that cause metal corrosion and destroying insulation of current conductors and electric

elements, free of current-carrying dust or water vapor, and preventing ingress of water, steam,

fuel and lubricants.

Climatic conditions of operation

– У3.1 as per GOST 15150-69 with extended temperature

range:

ambient temperature: from -

30 to +50 °С;

Relative air h

umidity: not higher than 98% at 25°С or lower temperatures without moisture

condensation and hoar-frost formation;

installation indoors or outdoors excluding ingress of moisture, dust, dirt, etc. inside the lock.

1

– Lock

1 pc.

2

– Latch with adjustment plate

1 pc.

3

– Alignment piece

1 pc.

4

– Self-tapping screw 3.5х15 (cup head)

6 pcs.

5

– Operating manual

1 pc.

.

.

1

2

3

4