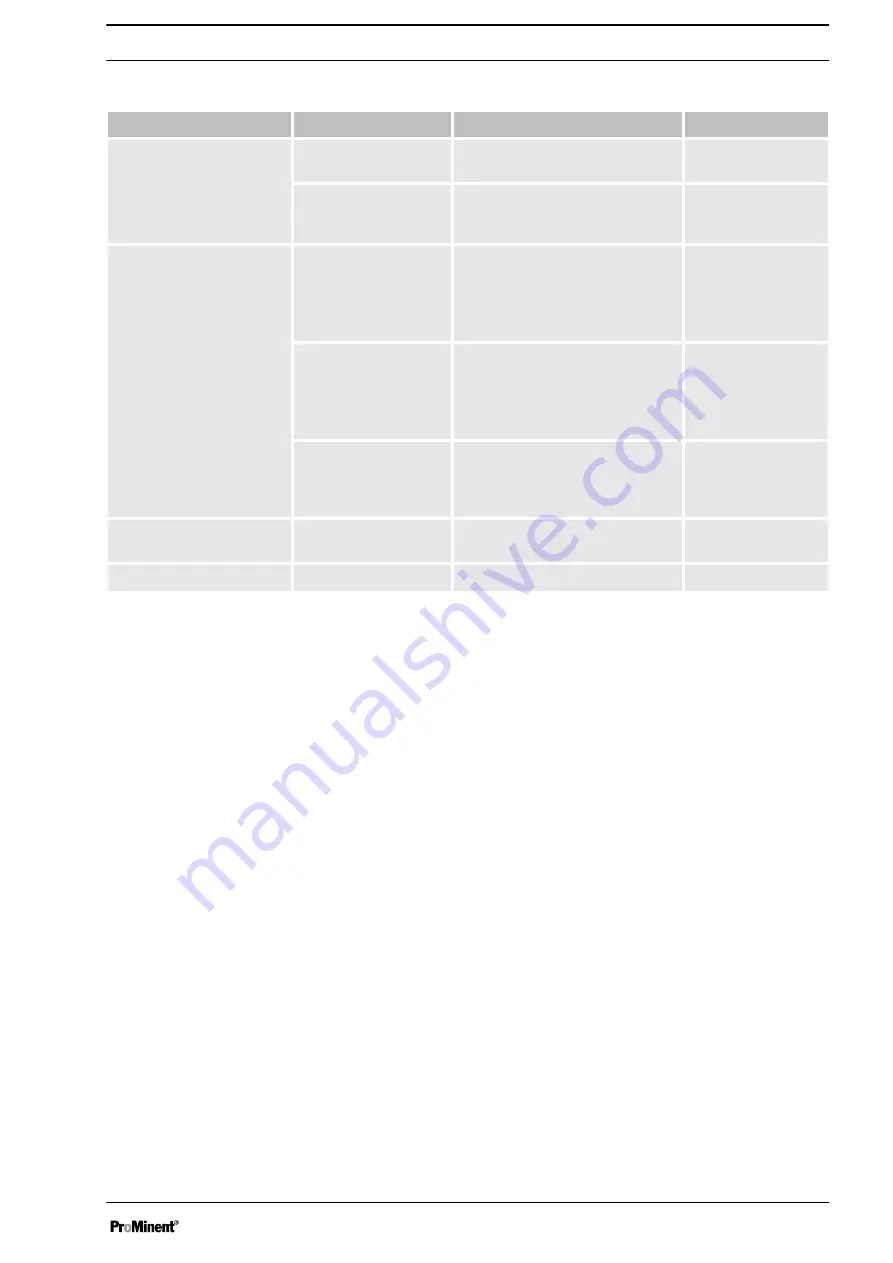

Fault description

Cause

Remedy

Personnel

Pump fails to pressurise

or does not prime in

despite full stroke motion

and bleeding.

The valves are dirty

or worn.

Repair the valves - see chapter

entitled "Repair".

Technical personnel

The feed chemical

has particles larger

than 0.3 mm.

Install a suitable filter in the suc‐

tion line.

Technical personnel

Pump does not reach

high pressure rates.

The motor is wired

incorrectly.

1. Check the mains voltage and

mains frequency.

2. Wire the motor correctly.

Electrician

Electrical technician

with additional

explosion protection

qualification

The mains voltage

has failed.

Eliminate the cause.

Electrician

Electrical technician

with additional

explosion protection

qualification

Operating diaphragm

ruptured and alarm

has not sounded. **

n

Replace the operating dia‐

phragm immediately - refer

to the "Repair" chapter -

"Changing the diaphragm".

Technical personnel

The power end motor is

very hot.

The discharge line is

seriously constricted.

n

Rectify any constriction of

the discharge line.

Technical personnel

All other faults.

Other causes.

Call ProMinent

®

Service.

Tasks

Troubleshooting

69

Содержание Makro TZ

Страница 45: ...Install the other units in line with their documentation Other units Installation 45...

Страница 99: ...99...