Prodigy

r

Manual Powder Spray Gun

7

Part 1053680E05

E

2007 Nordson Corporation

Installation

(contd)

6. Push the delivery tubing into the adapter (20)

until it bottoms out against the powder tube

(21). Thread the lock knob into the adapter and

finger-tighten it until snug.

7. Route the delivery tubing to the appropriate

powder pump. Remove the outlet fitting (rear

fitting) and O-ring and install them on the

tubing, then screw the fitting back onto the

pump.

8. Connect suction tubing as described in the

powder pump manual or Color-on-Demand

installation manual.

9. Use cable ties or spiral-cut tube wrap to bundle

together the gun control cable, pattern air

tubing, and powder tubing.

ATEX Special Condition For Safe Use:

This applicator shall only be used with the Prodigy

Manual Controller.

Operation

WARNING: This equipment can be

dangerous unless it is used in

accordance with the rules laid down in

this manual.

All gun functions are set and controlled by the

manual gun controller.

Presets

A preset is a group of spray settings. The gun

controller provides 10 presets. Use the presets to

save optimal spray settings for parts with different

features.

Gun ON LED

The LED on the end plate lights when the spray

trigger is pulled and high voltage is generated.

Pattern Control Trigger

The pattern control trigger toggles between the

preset settings (High mode) and the Low mode

settings. Use it to change the pattern air and

powder flow as needed when part features change.

When in Low mode, a down-pointing arrow (

⇓

) is

appears to the right of the gun icon.

NOTE: If you change presets while spraying in

Low mode, the controller immediately switches to

High mode, spraying with the new preset settings.

Maintenance

WARNING: Inspection and maintenance

of this equipment in Europe shall carried

out by suitably trained personnel in

accordance with the applicable code of

practice. EN60079-17

Daily: Blow off the gun exterior with low-pressure

compressed air and wipe it clean with a soft cloth.

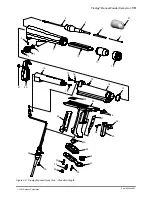

Weekly: Manually perform a hard purge, then

remove the retaining nut, nozzle, and powder tube.

Inspect the powder tube and nozzle for wear.

Replace any worn parts.

Periodically: Check the resistance of the voltage

multiplier and resistor with a megohm meter as

described in Continuity and Resistance Checks on

page 11. Replace any components that do not

meet the specifications.

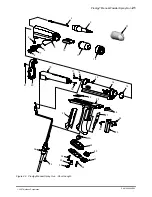

As Required: Disassemble the nozzle and clean

the internal parts. Replace any worn parts. Refer

to Nozzle Disassembly and Cleaning on the

following page for instructions.

Содержание Powder Spray Gun

Страница 28: ...Prodigyr Manual Powder Spray Gun 26 Part 1053680E05 E 2007 Nordson Corporation...

Страница 30: ......