5

Copyright © 2020 Quality Machine Tools, LLC

PM-835S v3 2020-10

Section 2 INSTALLATION

Cleanup

Finished metal surfaces such as the ways and table are pro-

tected in shipping by grease and/or paper. After uncrating the

mill, clean the finished surfaces using a plastic paint scraper,

disposable rags, and a light oil such as WD-40.

Reverse the hand cranks, if they were installed inside out for

shipping (or they may have been shipped loose).

Preliminary oiling

Before cranking the table, knee, saddle and ram into position

for hoisting, apply oil to the ways using the one-shot oiler — a

couple of pump strokes should be sufficient. Crank the table,

knee and saddle through at least one end-stop to end-stop

cycle. If the lube reservoir is empty, replenish with Mobil Vactra

No. 2 or equivalent (see Section 4, Maintenance).

Moving the head

If it is necessary to swivel the head for hoisting purposes, par-

tially loosen the four head mounting bolts, Figure 2-1,

while

supporting the head

to prevent sudden movement. Continue

supporting the head while using a wrench on hex head #1,

Figure 2-2, to crank the head to the desired position. Tighten

the bolts in the diagonal sequence, Figure 2-1, first pass at 25

lb-ft torque, second pass at 50 lb-ft. Over-tightening can distort

the head, causing the quill to bind.

Do not move the table, saddle, knee — or any

other movable part — until everything has been

thoroughly cleaned and lubricated, see below

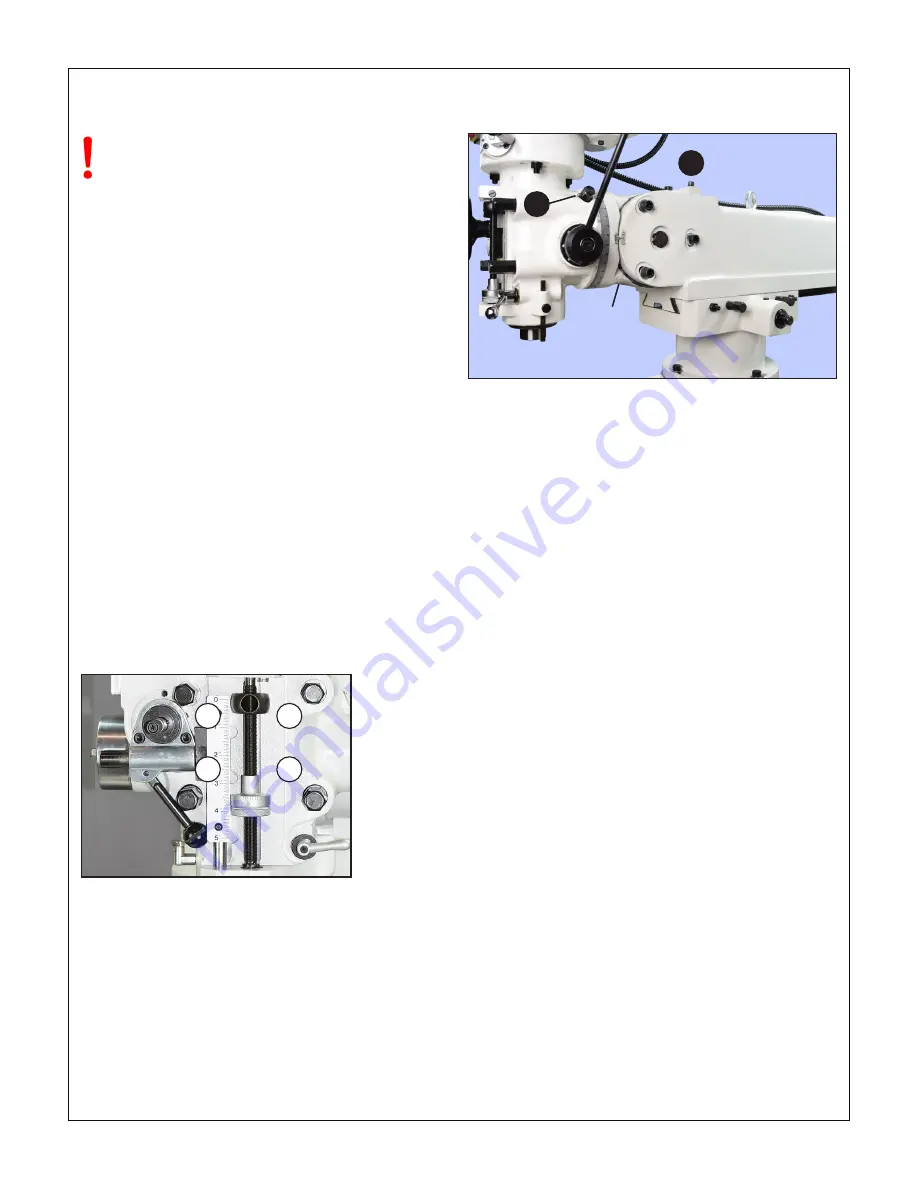

Figure 2-2

Head swivel & head forward/backward tilt

Use a hex wrench to crank the head clockwise/counter-clockwise (1)

—

support the head manually while turning to ease pressure on

the worm

. Socket head cap screw (2) bears on a ledge on the head

support casting, allowing a few degrees angular adjustment forward

and back.

Site preparation

The floor must be capabl

e of rigidly supporting a weight of at

least 1 ton. If possible, secure the mill to the floor with anchor

bolts. Alternatively, use pads and leveling screws installed in

holes in the machine base (pads are available from Precision

Matthews).

If the machine is to be bolted down, be sure that all four cor-

ners of the base are

solidly

in contact with the floor

after the

machine has been leveled

, see below. Use metal shims to

correct if necessary.

Lifting the mill

See Figures 2-3 and 2-4 for alternatives. Go slow! Check for

balance as the mill is clearing the pallet or floor. It may be nec

-

essary move the head for clearance, and/or to adjust the knee,

table and ram for balance.

Leveling

Check for clearance

around the mill before settling on its final

location. Using a precision machinist’s level check the table

lengthwise (X) and crosswise (Y), shimming as necessary un-

der the base, or adjusting the leveling screws.

Figure 2-1

Head mounting bolts

The numbers indicate the correct (diagonal) tightening sequence.

2

3

1

4

Head

support

casting

1

2