11

Copyright © 2020 Quality Machine Tools, LLC

PM-835S v3 2020-10

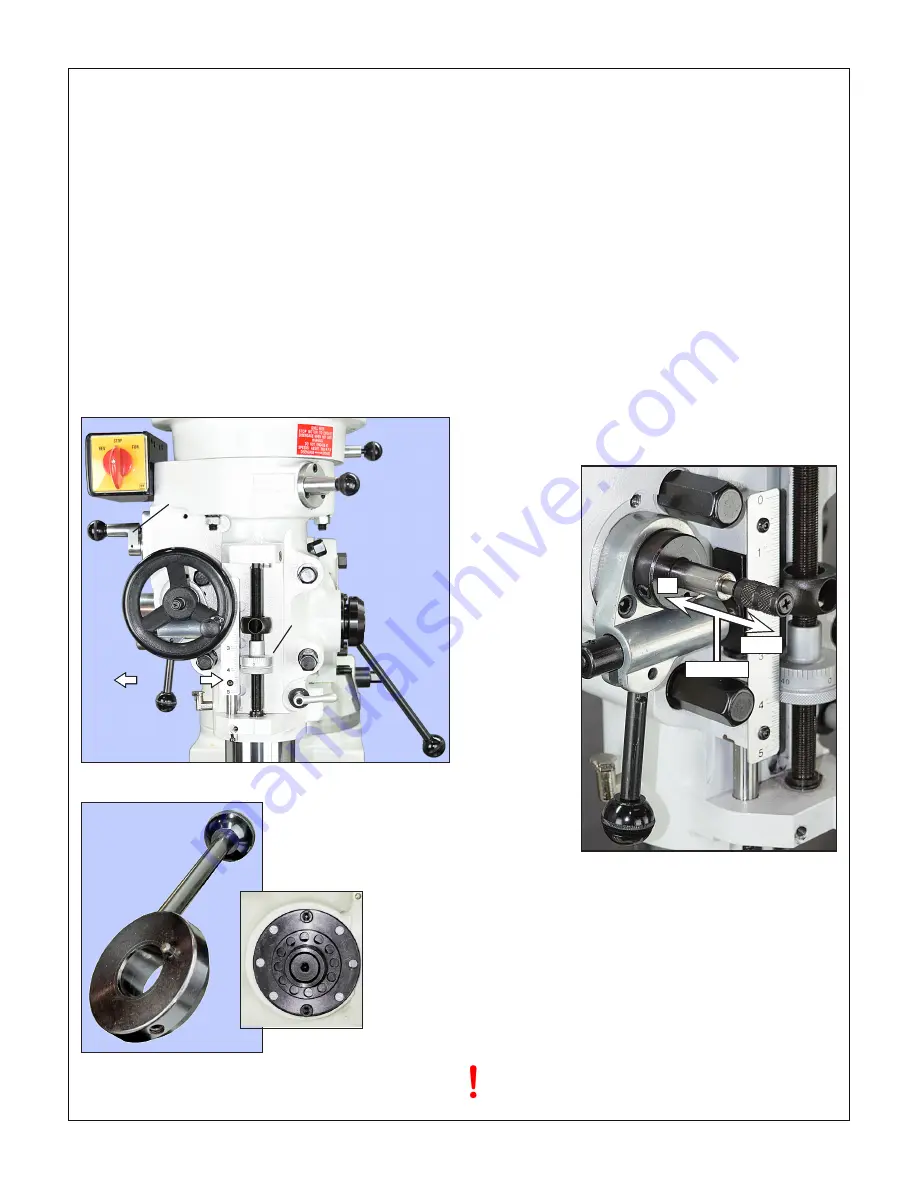

QUILL DOWNFEED

The

quill is moved in three different ways: manual

coarse

,

manual

fine

, and

powered

(auto quill feed).

Coarse manual downfeed

In this mode the mill functions like a standard drill press —

lower the quill using the quill manual feed handle, Figure 3-11.

Before operating the manual feed handle, unlock the quill.

Stop the spindle and disengage the quill auto feed (crank at

right of the head).

The feed handle hub, Figure 3-12, is held on the quill pinion

shaft by a spring-loaded ball and a detent groove on the outer

end of the shaft. A pin on the hub locates in one of 12 holes in

an index plate keyed to the shaft.

To reposition the manual feed handle relative to the index

plate, pull the hub about 1/4” away off the plate, then re-index

the hub to a different location.

Figure 3-12

Quill manual feed handle and index plate

Quill manual

feed handle

Quill auto

feed ON/OFF

(engaged/dis-

engaged)

Feed rate

selector

ON OFF

Figure 3-11

Quill controls

Fine feed handwheel

Quill lock

Micrometer

depth stop

Quill auto

feed lever

Fine manual downfeed

For milling operations calling for better control of tool depth,

use the fine feed handwheel.

1. With the spindle

stationary

, disengage the quill auto feed

(crank at right of the head).

2. Unlock the quill.

3. Set the quill auto feed direction plunger to neutral (mid

position), Figure 3-13.

4. Swing the quill auto feed lever to the left.

The quill is now under handwheel control.

NOTE 1:

Clockwise rotation of the handwheel causes the quill

to descend.

NOTE 2:

The handwheel is often removed for better visibility

of the micrometer scale.

NOTE 3:

In common with other knee mills there is no indica-

tion of down feed amount unless a DRO is installed on the

quill. Most users control cutting depth by locking the quill then

raising the knee in precise increments.

Figure 3-13

Auto feed direction plunger

Moving the plunger from fully in to fully out reverses feed direction.

The center position is neutral, no down feed. UP and DOWN direc

-

tions here apply to clockwise spindle rotation — vice-versa for count

-

er-clockwise rotation.

UP

DOWN

NEUTRAL

QUILL AUTO FEED

The auto feed system can be set to drive the quill either up or

down at a choice of three speeds, Figure 3-14. A clutch mech-

anism disables the drive when overloaded (as shipped, the

clutch is adjusted for a drilling capacity of about 3/8” in mild

steel).

Be sure the quill is unlocked before auto feeding