P

RO

V

U

™ PD6088/PD6089 Modbus

®

Scanner

Instruction Manual

62

Troubleshooting

This scanner is a highly sophisticated instrument with an extensive list of features and capabilities. If the front panel

buttons are used to program the scanner, it may be a difficult task to keep everything straight. That is why we strongly

recommend the use of the free

ScanView

software for all programming activities. A cable is provided with the scanner

for programming with Scan software.

If you have programmed the scanner with the front panel buttons and it is not working as intended, try re-

programming the scanner using ScanView software.

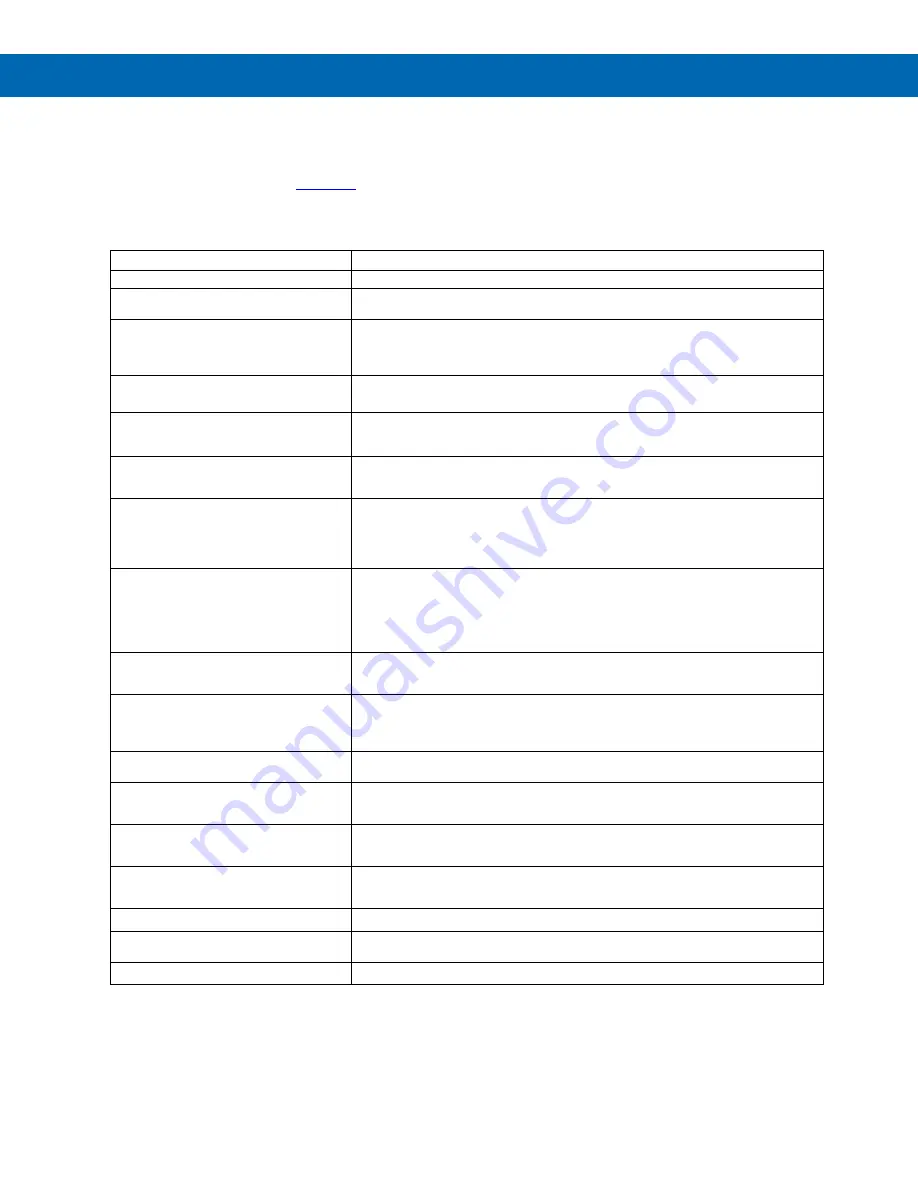

Symptom

Check/Action

No display at all

Check power at power connector

Not able to change setup or programming,

Locd

is displayed

Scanner is password-protected, enter correct six-digit password to unlock

Scanner does not respond to input

change

If a

Low-Flow Cutoff

Value has been programmed, the scanner will display zero

below that point, regardless of the input

– which can appear like the scanner is not

responding to an input change. Check to make sure the problem is not being caused

by an undesired low-flow cutoff value.

Scanner displays error message during

scaling (

Error

)

Check:

Input 2 must greater than Input 1, Input 3 must be greater than Input 2, etc.

Scanner displays

1.

999999

2.

-99999

Indicating overrange or underrange condition

Check the input data value and scaling in

Setup

menu

Display stop scanning,

■ LED indicator

flashing

Check:

1.

Stop on alarm feature has been enabled

2.

Press PREV or NEXT to resume scanning

Displays

break

message

Check:

1.

RS-485 connection to slave devices

2.

Slave Id, register number of slave devices

3.

Baud rate and parity of all devices on the bus

4.

Scanner Id must be different from other devices

Snooper mode not reading the PVs on the

RS-485 bus

Check:

1.

Increase Master’s Transmit Delay

(e.g. Snooper delay = 100ms, Master delay = 110ms)

2.

Increase Snooper’s byte-to-byte timeout

3.

Decrease the slave device’s transmit delay to <10ms

4.

Snooper cannot read the same PV twice, check setup

Scanner experiencing faults and

communication breaks

Check:

Increase response time (

t-resp

) and/or transmit delay (

tr dly

). This may require

some trial and error, as these are dependent upon the number of devices on the bus.

Scanner not communicating with

ScanView software

Check:

1.

Serial adapter and cable

2.

Serial settings

3.

Scanner address, baud rate, and transmit delay

Display does not respond to input data,

reading a fixed number

Check:

Display assignment, it might be displaying max/ min

Display reading is not accurate

Check:

1.

PV Scaling

2.

Check format selected: Dec or Ft&In

Relay operation is reversed

Check:

1.

Fail-safe in

Setup

menu

2.

Wiring of relay contacts

Relay and status LED do not

respond to signal

Check:

1.

Relay action in

Setup

menu

2.

Set and reset points

Flashing relay status LEDs

Relays in manual control mode or relay interlock switches opened.

If the display locks up or the scanner does

not respond at all

Cycle the power to reboot the microprocessor.

Other symptoms not described above

Call Technical Support for assistance.

Note: Certain sequences of events can cause unexpected results. To solve these issues, it is best to start fresh from factory defaults

and use the manual as a step by step programming guide, rather than a random approach to programming. To reset the scanner to

factory defaults, see Reset Scanner to Factory Defaults on page 63. In addition, for best results, we recommend using the free

ScanView software for all programming needs.