7

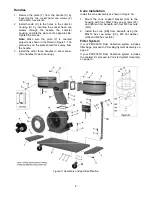

Base Machine Assembly

The dust collector must not be

connected to the power source

during assembly.

All instructions on this page refer to Figure 3.

Base and Base Extensions

1. Attach

the

base extensions

(L) to the

base

(K)

by inserting M8x20

hex head screws

(A)

through the mounting holes of the

extension

(L)

and

base

(K).

2. Place

M8

flat washers

(D) and M8

lock washers

(G) on the ends of the

screws

(A) and fasten

with M8

hex nuts

(F), using 13mm wrenches.

Casters

1. The

3/8”

hex nut

(H) and M10

lock washer

(J)

are pre-assembled to each

caster

(M). For

shipping purposes, the lock washer has been

placed beneath the hex nut. Remove hex nut

and lock washer from the caster shaft, re-install

the hex nut, then install the lock washer

above

the hex nut, as shown.

2. Install the four

casters

(M) to the underside of

the

base

(K) as follows:

3. Thread the caster shaft into the threaded hole

on the underside of the

base

(K), turn until

snug. Tighten the

hex nut

(H) against the base

with a 14mm wrench.

Motor and Impeller Assembly

1. Place the base with casters down on the ground.

2. Attach

the

motor and impeller assembly

(N) to the

base

(K) using six M8x20

hex cap screws

(A),

and six

M10

flat washers

(E). Hand tighten only

until all screws and washers are in place, then

tighten all six screws with a 13mm wrench.

3. Attach

the

impeller plate

(O) to

impeller housing

(N) using eight M6x12

pan head flange screws

(B).

4. Press

the

inlet port

(P) onto the

impeller plate

(O)

until it snaps into place. Secure in place with

3/16” x 1/2”

pan head flange screw

(C).

To reduce the risk of injury from

moving parts, always keep inlet port (P) covered

with the caps provided, if they are not connected

to a hose.

Connector Tube and Switch Box

1. Place the

lower gasket

(Q) on the

impeller

housing

(N). Line up the rubber pegs on the

gasket (face down) with the holes in the housing.

2. Place the

connector tube

(R) on the

impeller

housing

(N), making sure that the holes of the

mating flanges are aligned.

Note:

Refer to Figure 3 to make sure that the

connector tube is facing the proper direction.

3. Insert an M8x20

hex cap screw

(A), through the

M8

washer

(D) and flanges of the

connector tube

(R) and

impeller housing

(N).

4. Place

another

washer

(D) and a

hex nut

(F) on

the protruding end of the

screw

(A) and hand-

tighten only.

5. Mount

the

control box

(S) to the two holes at the

front of the

connector tube

flange (R).

6. Repeat steps 3 and 4 for the remaining screw

locations, hand tightening only.

7. Tighten all hex nuts with a 13mm wrench.

Collector Housings

Mount the

right collector housing

(V) as follows:

1. Place

an

upper gasket

(T) between the

collector

housing

(V) and

connector tube

(R). Line up the

pegs on the

gasket

(T) with the holes in the

housing

(V).

2. Place

the

collector housing

(V) on the

connector

tube

(R). Make sure to properly orient the

collector housing – the internal baffle must slope

downwards toward the center.

3. Insert a

screw

(A) through the

washer

(D),

connector tube flange

(R), and

collector-housing

flange

(V).

4. Place

another

washer

(D) and a

hex nut

(F) on

the protruding end of the

screw

(A) and hand-

tighten.

5. Repeat steps 1 through 4 for the seven remaining

screw locations.

6. Tighten all screws and hex nuts with a 13mm

wrench.

7. Repeat steps 1 through 6 for the

left collector

housing

(U).

Support Bars

1. Align the bottom slots of a

support bar

(W) with

the holes in the

base

(K). Insert two

screws

(A)

with two

flat washers

(D) and hand tighten only.

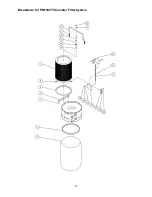

Note:

If you are using the Canister Filter

System, proceed with steps 2 through 5 below.

If you are using the Filter Bag System, leave

the support bar (W) as is, for further assembly

later, and proceed to “Handles”.

2. Align the top holes of the

support bar

(W) with

the holes at the rear of the

collector housing

(V)

and insert two

screws

(A) and two

flat washers

(D).

3. Place

a

washer

(D) and a

hex nut

(F) on the

protruding end of each

screw

(A) inside the

collector housing, and hand-tighten only.

4. Adjust the lower part of the

support bar

(W) as

needed using its slots, until it is straight. Then

tighten all four screws on the

support bar

(W).

5. Repeat for the other support bar.