10HP - 20HP Scroll Enclosure Air Compressors

Pg 2

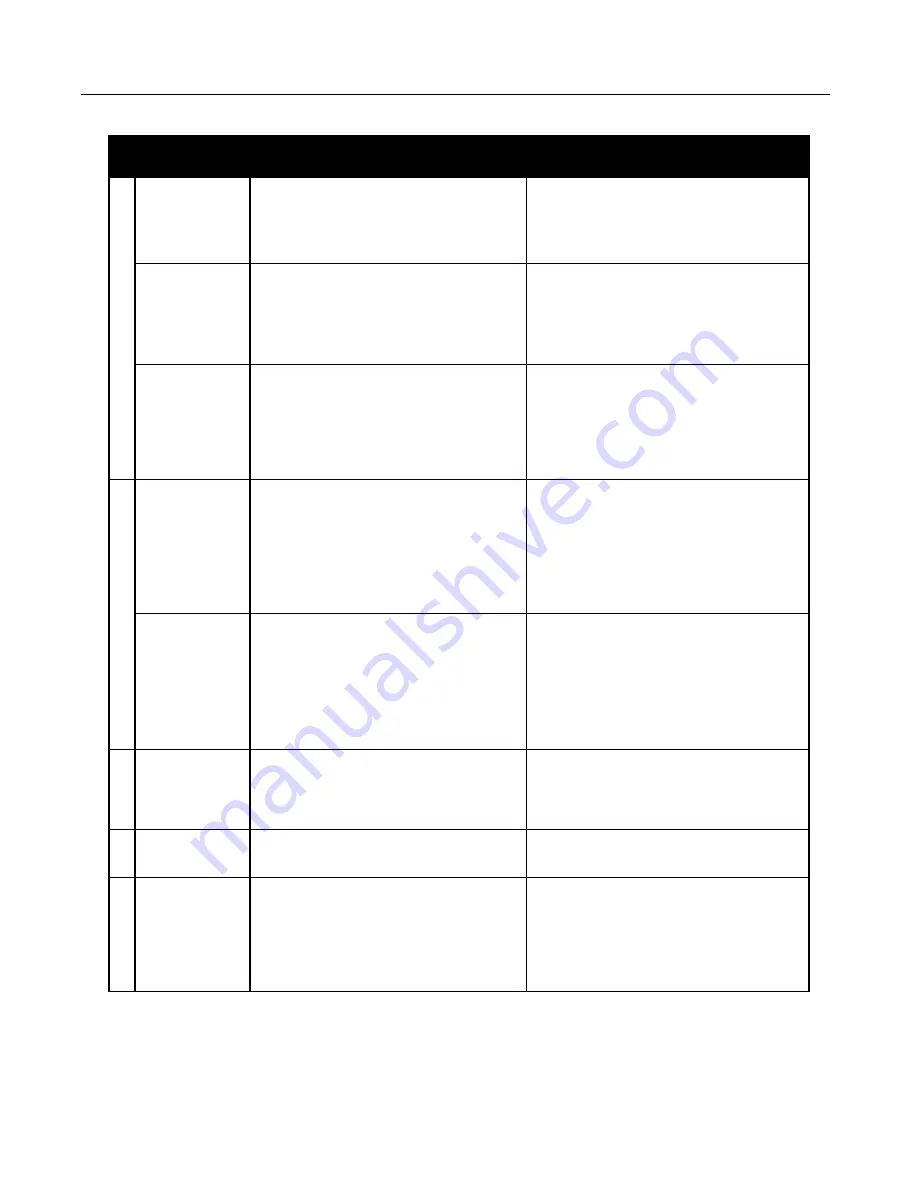

TROUBLESHOOTING GUIDE

Problem

Possible Cause

Corrective Action

Comp

re

ssor doe

s n

ot ope

ra

te

No Display on the

Operating Panel

1. The electric source is not turned on

2. Transformer primary or secondary fuse open

3. Electric source is not correctly connected

4. Failure of display or PLC

1. Turn on electric source

2. Replace

3. Connect correctly

4. Inspect, repair or replace

It does not operate

despite displays

1. Failure or wiring failure of magnetic starter

2. Motor failure

3. Low voltage

1. Inspect, repair or replace

2. Inspect, repair or replace

3. Check electric source capacity and the size of

electric source cable and change to proper one

Alarm Screen

Active

1. High temperature condition

2. Motor Overload condition

3. High temperature indicated but unit is cool,

has never been hot

1.Allow to cool and reset, determine cause

2. Reset motor overload, reset alarm and

determine root cause of overload

3. A temperature switch may be disconnected or

defective, check wiring

Compressor starts but then st

ops

Alarm Screen

High Temperature

1. High ambient temperature or bad ventilation

2. Clogging of aftercooler fins or intake wire

screen

3. Failure of ventilating fan

4. Damage to intake hose

5. Cooling passage of air end clogged

6. High exhaust pressure

1.Improve installation environment & ventilation

2. Clean

3. Replace

4. Replace

5. Inspect and clean

6. Inspect– control malfunction likely

Alarm Screen

Motor Overload

1. Low voltage

2. Motor Failure

3. Air end failure

4. Loosened wiring screw

5. High exhaust pressure

6. Failure of thermal overload

1. Check electric source capacity, size of electric

source cable and change to proper one

2. Inspect, repair or replace

3. Inspect, repair or replace

4. Tighten

5. Inspect - control failure likely

6. Replace

Exhaust pressure

does not increase

1. Air leaks from exhaust piping

2. Air-end rotates backward

3. Wrong pressure setting

4. Clogged intake filter

1. Inspect, repair

2. Change phases

3. Readjust

4. Clean or replace

Safety valve

activates

1. Failure of safety valve

2. Failure of pressure setting

1. Replace

2. Inspect - control failure likely

Abnormal sound

1. Air-end rotates backward

2. Air end failure

3. Belt slips

4. Motor failure

5. Cooling fan contacting frame

6. Loosened bolts

1. Change phases

2. Inspect, repair or replace

3. Check tension and readjust

4. Inspect, repair or replace

5. Inspect and repair

6. Inspect and tighten