Power-Flo Pumps & Systems • 877-24PUMPS • www.powerfl opumps.com

7

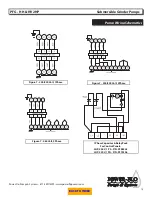

Dimensions

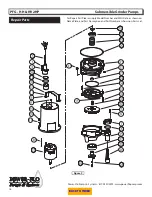

Receiving & Installation

Receiving Inspection

Upon receiving the pump, it should be

inspected for damage or shortages.

If damage has occurred, file a claim

immediately with the company that

delivered the pump. If the manual is

removed from the packaging, do not

lose or misplace.

Storage

Any product that is stored for a period

longer than six (6) months from the

date of purchase should be bench

tested prior to installation. A bench

test consists of, checking the impeller

to assure it is free turning and a run

test to assure the motor (and switch

if provided) operate properly. Do not

pump out of liquid.

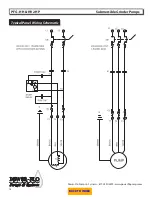

Controls

PFG series grinders require a separate

approved pump control device or panel

for automatic operation. Be sure the

electrical specifi cation of the control

selected properly match the electrical

specifi cations of the pump.

Location

The grinder pump is designed to fi t

in basin or wetwell by using a slide

rail system (with legs removed) or

by resting on fl oor of basin with legs

attached.

IMPORTANT ! - A CLEARANCE

UNDER THE PUMP FOR

ENTRANCE OF SEWAGE SOLIDS

MUST BE A MINIMUM OF 3

INCHES TO A MAXIMUM OF 4.5

INCHES.

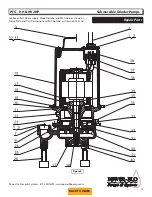

Submergence

The pump should always be operated in

the submerged condition. The minimum

sump liquid level should never be less than

above the pump’s volute (See Figure 1).

Recommended

Submergence Level

Minimum

Submergence Level

Bottom of Feet

8”

Figure 1

PFG - HH & HV 2HP

Submersible Grinder Pumps

BACK TO INDEX