V1.0

5/16 in. Straight Grip Air Punch and Flange Tool

8843773

Visit www.princessauto.com for more information

9

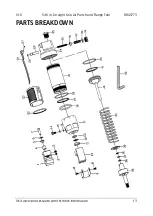

FLANGING

IMPORTANT! If you intend to flange and punch the workpeice, flange it first

and then measure for hole placement. Flanging will change the dimensions

of the workpiece.

1.

Measure and cut the workpiece to the correct dimensions.

2. Secure the workpiece in a vise or another appropriate clamping

method if needed.

3.

Insert the workpiece into the flanging jaw between the anvil (F) and

the clamp (E). Make sure that the workpiece is flush against the back

of both the anvil and the clamp. Depress the trigger (D) and the anvil

will be driven against the clamp forming a flange.

4.

Release the trigger. Slide the punch/flange tool (G) along the edge of

the workpiece to where the anvil (F) and the clamp (E) overlap part of

the workpiece you just flanged. Repeat Step 3.

5.

Repeat Steps 3 and 4 until the entire length you wanted to flange is

finished.

6. Disconnect the tool from the air supply..

PUNCHING

The tool head can rotate 360 degrees. Twist the tool head 180 degrees in

either direction to match the workpiece’s angle.

1.

Mark the desired location on the workpiece of each hole you wish to

punch.

2. Insert the edge of the workpiece between the punch die (A) and punch

(B). Make sure that your marks are aligned with the punch die.

3.

Depress the trigger (D) and the punch will pierce the workpiece.

4.

Align the punch/flange tool with the next mark on the workpiece and

repeat Step 3 until the job is finished.

5.

Disconnect the tool from the air supply.

PRESSURE DROP

Apply the air consumption and pressure rate numbers to the tool’s air inlet, not

the compressor’s outlet. Calculate the pressure drop for your air supply set-up

and increase the compressor outlet pressure to compensate. Make sure you do

not exceed the maximum pressure for any part of your air supply system.

Installing a pressure gauge at the tool inlet is the best way to measure the

air pressure and adjust the compressor’s output.