V4.0

Metal Punch Kit

8639106

Visit www.princessauto.com for more information

5

Contents:

•

Hex ratchet wrench, 1/2 in.

•

Socket, 19 mm

•

Round punches and dies (see Specifications)

•

Draw stud with bearing, 3/8 in. 24UN

•

Draw stud with bearing, 3/4 in. 16UN

OPERATION

Dashed numbers in parenthesis (Fig. 1-1) refer to a specific point in an

illustration or image.

Each conduit punch has the metric diameter listed on the side. This indicates the

hole size that the punch will create. See Specifications for the diameter in inches.

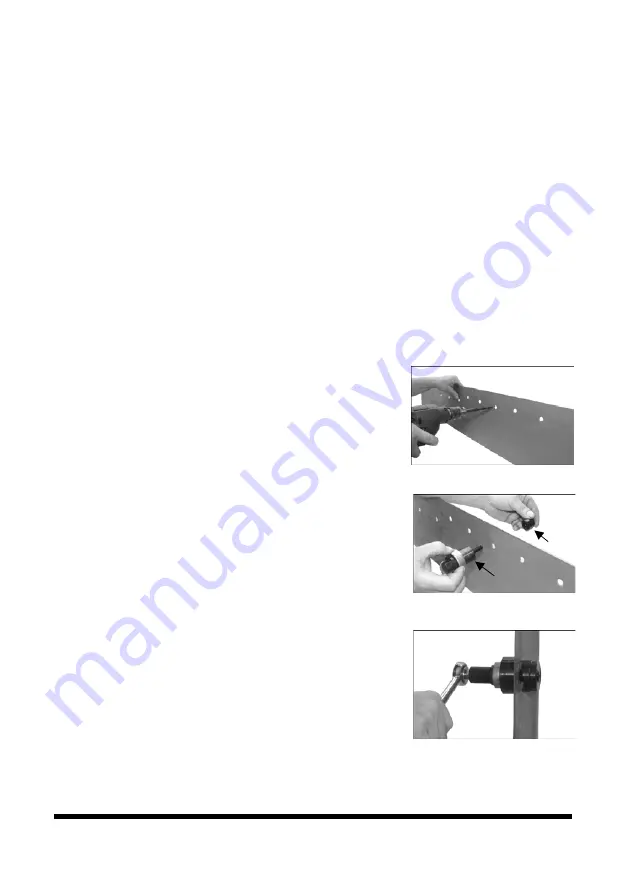

1. Choose the conduit punch size to apply to the workpiece.

a. Drill a 3/8 in. pilot hole if choosing the

57/64 in. punch (Fig. 1).

b. Drill a 3/4 in. pilot hole if choosing the

1-1/8 in. or larger punch (Fig. 1).

2. Separate the punch from the cutting die. Slide

the punch onto the draw stud that matches the

pilot hole with the cup side facing the material

(Fig. 2-1). Insert the draw stud through the pilot

hole (Fig. 2-1). Screw the punch onto the draw

stud with the cutting blades facing the

workpiece (Fig. 2-2). Tighten by hand until the

blades touch the workpiece

3. Place the 19 mm socket over the end of the

draw stud. Click the ratchet’s driver into the

socket (Fig. 3).

4. Turn the draw stud for force the blades to cut

through the material. Continue turning until the

punch completes the hole. The punch unit

(punch, die and draw stud) may fall free, toward

the die side, when the hole is complete.

Fig. 1

Fig. 2

2-1

2-2

Fig. 3