0450071

INSTALLATION

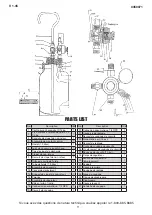

1. Set the air pressure regulator on the air compressor to 90 PSI.

2. Prepare a standard 1/4" air connector for use with your tool.

Wrap the threaded portion of the air connector with thread tape.

Attach it to the tool's air inlet. Tighten securely.

Note :

If you are not using an in-line oiler, add a few drops of air tool oil

in the tool's air inlet before use. In the same manner, add a few

drops after every hour of use.

3. Attach a standard quick connector to the air source's hose.

Attach the air hose to the tool.

Warning:

Do not exceed the tool's recommended air pressure. Excess

pressure could result in damage to the tool, to your work piece or

serious injury.

4. Check the air line and its connections for air leaks.

Do not use

this tool until you have repaired all air leaks.

Note:

Turn off the air compressor, disconnect the air pressure hose and

discharge any residual pressure inside the tool before changing

accessories or making any adjustments to the tool. Failure to do

so could result in severe injury, tool or property damage.

OPERATION

1. Suggested air pressure is 43 PSI

2. Recommended paint viscosity differs according to paint

properties and painting conditions.

3. Use the lowest possible fluid output that produces an

adequate paint coverage.

Finer atomization leads to a better

finish.

4. The gun should be held so that it is perpendicular to the

surface of the workpiece at all times.

Move the gun in a straight

and horizontal line. Arcing the gun results in an uneven paint

finish.

5. Keep a distance of 6" to 12" between the paint spray gun and

the surface to be painted.

6. In order to obtain a uniform finish during painting, keep the

paint spray gun perpendicular and at a constant distance

from the surface to be painted.

7. Spray the paint in horizontal swatches. If the finish is not

adequate, make sure that the pressure is not too low and that

the paint spray gun is not being held too far from the surface

to be painted.

Si vous avez des questions de nature technique, veuillez appeler le 1-800-665-8685

6

V 1.45

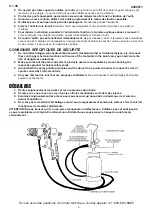

Fig. 3

Fig. 4

Fig. 2

CORRECT

Relâchez la

gâchette à

la fin de la

passe.

6 à 12 po

Commencez

à tirer sur la

gâchette.

La couche devrait être

uniforme et mouillée

lors de la vaporisation.

Parcours

du pistolet

Fig. 1

Couche trop

épaisse

INCORRECT

Couche trop

mince

ADJUSTMENT OF SPRAY

In normal operation the wings on the nozzle are horizontal as illustrated in Fig. 4. This

provides a vertical fan shaped pattern which gives maximum coverage as the gun is moved

back and forth parallel to the surface being finished.

1. The first requirement for a good finish is proper handling of the Spray gun.

The gun should be held

perpendicular to the surface being covered, and moved parallel with it. The stroke should be started before

the trigger is pulled and the trigger should be released before the stroke is ended. This gives accurate control

of gun and material. See Fig. 1 and Fig. 2.

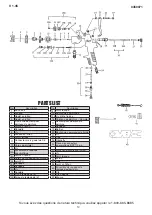

2. Adjusting spray pattern.

Turn the pattern adjusting knob completely to the right for a circular spray pattern,

completely to the left for oval shaped spray pattern

3. Adjusting spray volume.

Turn fluid control screw clockwise to reduce volume, counter-clockwise to increase

volume.

4. Adjusting air flow.

Turn the air regulator dial clockwise to reduce air volume, counter-clockwise to increase

air volume.

Réglage de la vaporisation

Vis de contrôle du fluide