Powered by Safety

®

20

Installation

01.4IB.51000C

PowlVac® Metal-Clad Switchgear

5kV & 15kV

Encircling loops of reinforcing or building

steel around single-phase conductors should

be avoided in the areas for main cables when

these circuits are rated at 600 amperes or

above.

The recommended practice is to weld the

switchgear structure to the floor channels,

using a tack weld at points indicated for

anchoring on the drawing. After welding, any

damaged paint should be removed, and the

weld and surrounding metal should be painted

to deter corrosion. If welding facilities are not

available, the switchgear should be bolted to

the floor channels.

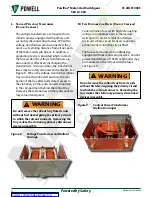

Figure 11 Recommended Floor

Finished Floor Line

Finished Floor Line

Recommended Method

Recommended Method

Door

Door

Floor Channels

Floor Channels

f. p

oSItIonInG

the

m

etAl

-c

lAD

S

WItchGeAr

1) Drawings and Diagrams

Before any installation work is done,

consult and study all drawings and the Bill

of Materials furnished by Powell for the

particular order. The drawings include

arrangement drawings and wiring and

schematic diagrams.

The recommended aisle space for the

front and at the rear of the metal-clad

switchgear is shown on the floor plan

drawing furnished for the particular order.

The space at the front must be sufficient

to permit insertion, withdrawal, and

transferring of circuit breakers. The space

at the rear must be sufficient for installation

of cables, for inspection and maintenance,

and on some switchgear to roll out

voltage or control power transformers.

The dimensions shown on the switchgear

drawings are those required for proper

operation of the switchgear.

When three or more switchgear units are

to be arranged in one continuous line-up,

the center shipping unit should be the first

located. The other shipping line-ups should

then be installed in successive order in each

direction from the center of the structure.

When installing a unit substation or power

center, the power transformer and the

adjacent metal-clad switchgear line-up

should first be lined up and set in position

in accordance with the dimensions on the

base plan drawing for the installation. The

additional units should then be installed.

Establish a base line located a few inches

in front of the units and parallel with the

desired front of the structure. Equalize the

distances from the front of the units to the

base line to make the face of the group

parallel to the base line.

Applicable national or local codes or

regulations may require greater aisle

space than is needed for operation of the

switchgear. It is the purchaser’s responsibility

to comply with these codes and regulations.

NOTICE