Publication No. 5105703

14 Installation

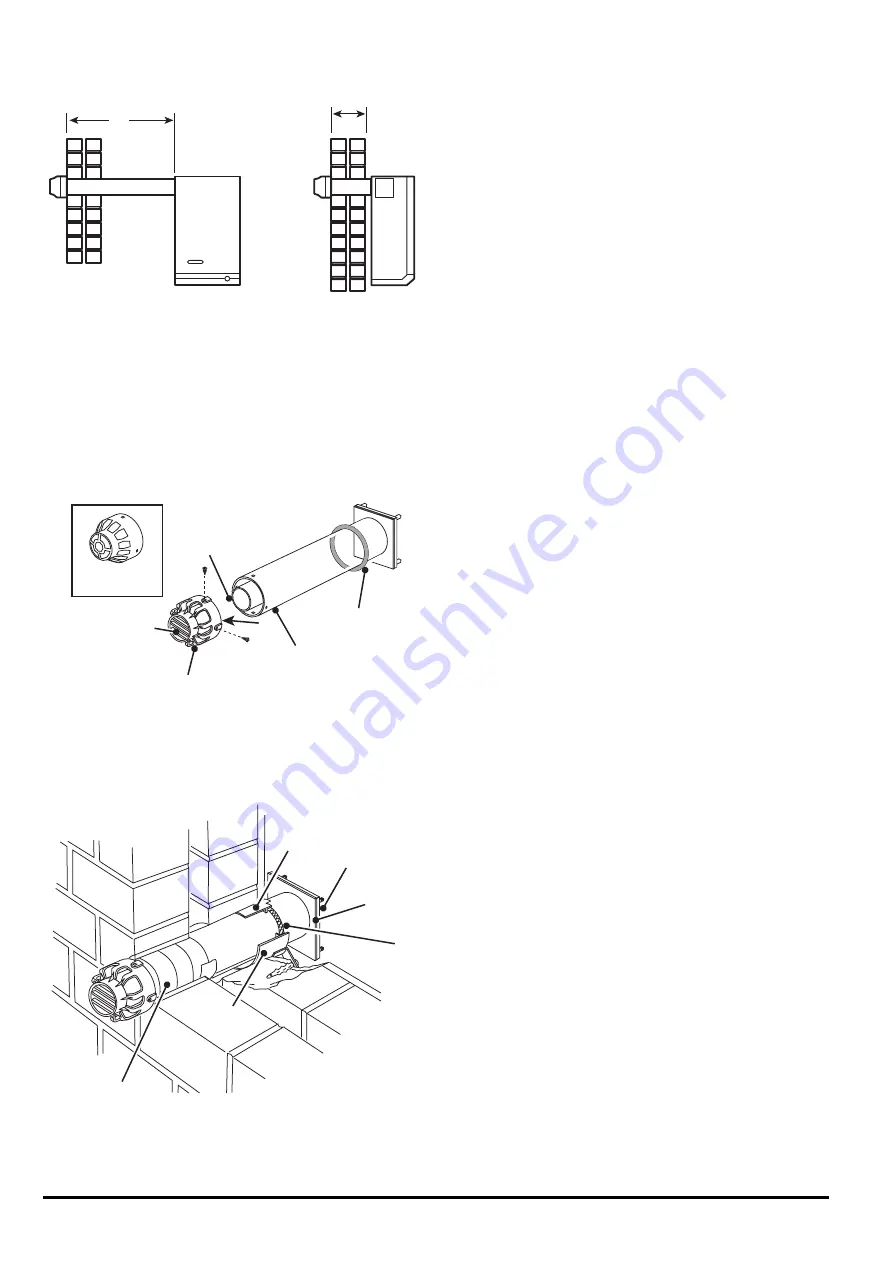

Fig. 13

2.4.

The Flue

Side Flue

1. Measure from outside face of wall to the

side of boiler casing reference line (dimension

'x').

2. Take air/flue duct assembly and measuring

from the flanged end mark and cut the outer

duct and inner flue duct to dimension 'x' plus

20 mm.

Ensure that both ducts are cut squarely.

Note: Cutting length remains the same for

minimum or maximum clearance at the rear of

the boiler.

Rear Flue

1. Measure wall thickness (dimension 'y').

2. Take air/flue duct assembly and measuring

from the flanged end mark and cut the outer

duct and inner flue duct to dimension 'y' plus

48 mm, or dimension 'y' plus 58 mm if boiler

mounting plate has been inverted.

Ensure that both ducts are cut squarely.

2.5.

Air/Flue Duct Assembly

Note: During assembly the seam in the air duct

should be so arranged that when installed, the

seam in the duct will be uppermost.

1. Slide rope sealing ring on to air duct.

2. Engage the terminal on to the ends of the

inner flue duct and press fully home.

Note: On 60 & 80 models there is a silicone seal

on the inner edge of the terminal. This is to

prevent recirculation of flue products.

3. Engage four screws from accessory pack C

into the pre-drilled holes in the terminal and

screw fully home.

These screws are self tapping on 60 & 80

models. These will pierce the air duct and

secure the terminal to it.

On the 40 and 50 models it is necessary to

drill four pilot holes in the air duct.

4. Protect the duct where it is likely to come

into contact with mortar by using adhesive

tape provided in accessory pack E.

PRF0014A

'Y'

'X'

PRF0015B

Rope Sealing

Ring

Air Duct

Terminal

40 to 50

Inner

Flue

Duct

Discharge

Vanes

PRF0016A

Sealing

Gasket

Air Duct

Flange

Rope

Sealing

Ring

Tab

Tab

Tape

Fig. 11

Fig. 12