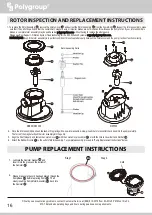

ASME COMPLIANT SUCTION FITTING INFORMATION

9. The suction outlet PSF-100A or PSF-100B is to be replaced every 5 years.

10. No tool is required for installation.

11. Service and Winterizing Instructions.

CAUTION! DO NOT EXCEED THE MAXIMUM ALLOWABLE FLOW RATE:

1. 45 Gallons per minute (2,700 Gallons per hour).

2. Carefully observe and inspect the suction outlet for damage and tampering before each use of the pool.

3. Missing, broken or cracked suction outlet must be replaced before using the pool.

4. Loose suction fitting should be reattached or replaced before using the pool.

5. Remove and store Suction Outlet assembly if temperatures are expected to fall below 32° F.

1. PSF-100A and PSF-100B Suction Outlets are certified by IAPMO in accordance with the ASME/ANSI A112.19.8b-2009 Suction Fitting for use in Swimming Pools,

Wading Pools, Spas, and Hot Tubs.

2. This is a submerged suction outlet for use with above ground swimming pools.

3. For single drain only. Use only ONE outlet for each pump.

4. Do not locate this suction outlet on sitting areas or on the backrest for such seating area.

5. Install this outlet at location recommended by the pool manufacturer.

6. The maximum allowable flow rate of this suction outlet is 45 gallons per minute (2,700 gallons per hour).

7. Connection Hose:

• Model PSF-100-A is to be connected with 1 1/4” (31.8mm) diameter hose.

• Model PSF-100-B is to be connected with 1 1/2” (38.1mm) diameter hose.

8. The suction outlet is to be mounted at the suction outlet opening as specified by the manufacturer of the above ground pool. The diameter of this opening should be

within the range of 1.77” to 1.85” (45.0mm to 47.0mm). Refer to the following diagram for detailed assembly instructions:

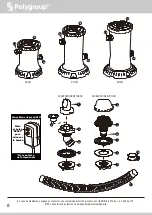

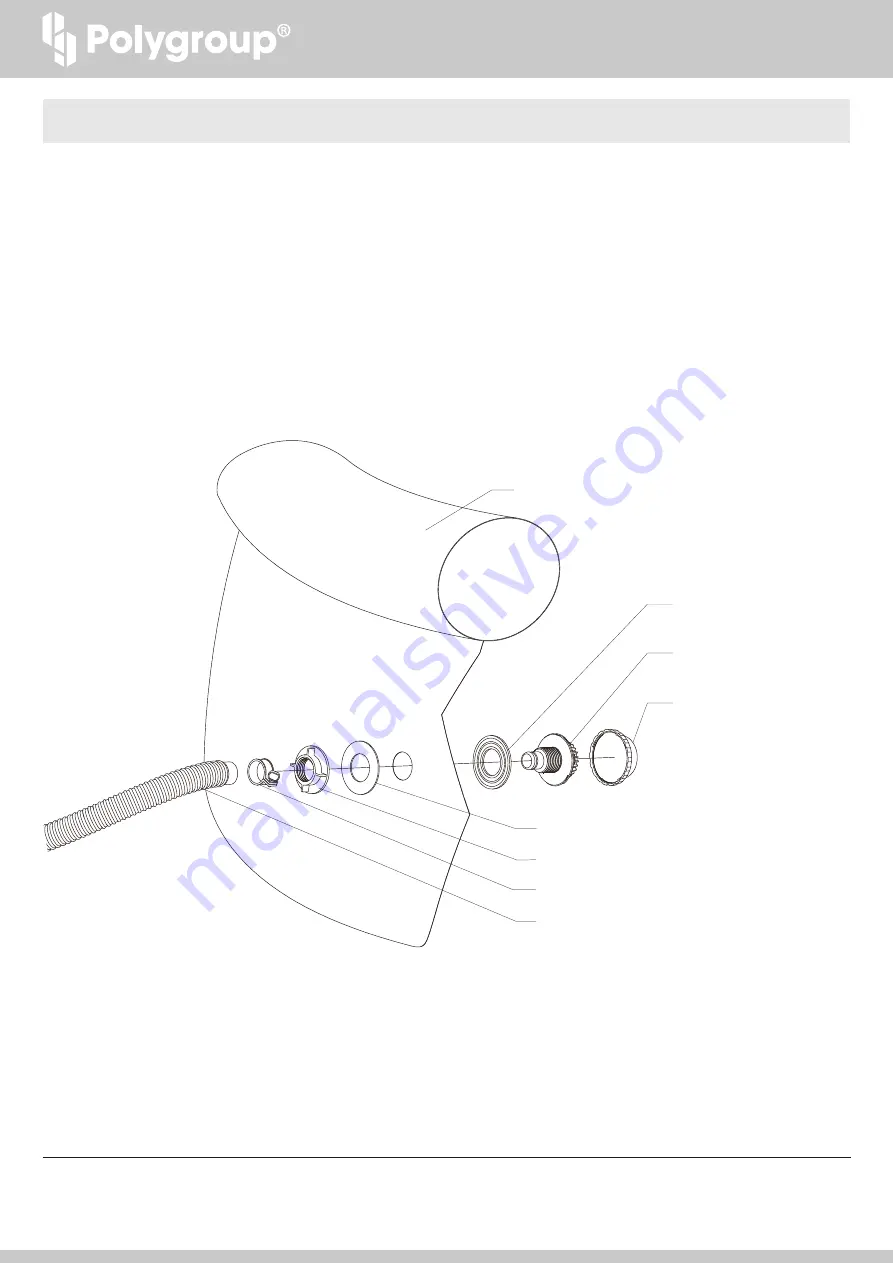

PSF-100A AND PSF-100B SUCTION OUTLET

(FOR ABOVE GROUND POOLS)

Swimming Pool

Water Hose

Hose Clamp

Lock Nut, To Be Tightened By Hand

Rubber Gasket

Water Cap, To Be Installed

Only During Pump Maintenance

Or Filter Change

Suction Fitting, PSF-100A

Or PSF-100B

Flat Washer

19

OWNER’S MANUAL

Should you encounter any problems, contact Customer Service at (888) 919-0070 from 8 AM to 5 PM Mon. thru Fri.

MST. Extended operating days and hours during peak season requirements.

Содержание SUMMER WAVES RX1000

Страница 20: ......