DD-75-181 R(2)

Y.T.13.07.17

16

Check/ tighten if required

Check

Check/ tighten if required

Check + Grease

Check

Check + Lubricate

Check

Check (free movement)

Check

Check (free movement)

Check + Adjust

Check / replace if required

Check

Check

Check

Check

Check

Check + Clean Dust

Check + Clean Dust

Check

Check +Clean Dust

Check

Anchoring nuts and bolts

Top cover / Lock/ Seals and drainage

Rotor arms/ bolts

Rotor bottom bearing

Rotor coupling and connections

Main rotor shaft

Clamp spring, damper arm bearing (manual type)

Lock levers and springs

Solenoids

Ratchet mechanism and spring

Hydraulic Damper (Manual type)

Hydraulic damper arm bearing

Motor (Motor driven type)

Motor pulley and drive belt (Motor driven type)

Mechanism mounting nuts and bolts

Mechanism Bearings

Power connections, wiring and grounding

Electronic Control Board

Positioning photosensor

Wiring and connectors

Motor Driver Board (Motor driven type)

Indicators and buzzer

12 Month

12 Month

12 Month

12 Month

12 Month

12 Month

12 Month

12 Month

12 Month

12 Month

12 Month

12 Month

12 Month

12 Month

12 Month

12 Month

12 Month

12 Month

12 Month

12 Month

12 Month

12 Month

General

Mechanism Assembly

Electrical Components

Full Height Turnstiles

Maintenance Item

Period

Recommended Action

7.2 Trouble Shooting and Repair Guide

7.1.2 Periodic Maintenance by Technical Service Personnel

Description of Fault

Possible Cause

Recommended Action

No power. (indicators, buzzer,

locks off)

Rotor free wheels when power

is on

Note: Ensure Emg. terminal is

not activated and dip switches

3 and 4 are off

Turnstile does not allow

passage when input contact is

given-buzzer heard

Rotor/arms do not return to

center (standby) position

following a passage

Rotor bounces back and forth

following a rotation, fails to

settle in rest position smoothly

1.

No AC power supplied to unit.

2.

Loose power cable

3.

Blown fuse

4.

Faulty power supply unit

1.

Loose solenoid or photo sensor

connector

2.

Faulty photo sensor

3.

Faulty solenoid

4.

Faulty control board

Note: periodic beep and red indicators

indicate a loose or faulty photo sensor.

1.

Restricted lock lever movement

(due to foreign object such as cable,

gummed lubricant etc.)

2.

Sticky solenoid

3.

Faulty control board

4.

Misaligned/bent photo sensor in

motorized units

1.

Loose or broken clamp spring

2.

Over damped hydraulic damper

setting

1.

Under damped hydraulic damper

setting

2.

Worn out / faulty hydraulic damper

1.

Restore AC power.

2.

Connect power cable.

3.

Replace fuse (see 2.2)

4.

Replace power supply unit

1.

Re-insert connector

2.

Replace photo sensor

3.

Replace solenoid.

4.

Replace control board

1.

Repair lever mechanism

2.

Replace solenoid

3.

Replace control board

4.

Adjust photo sensor (motorized

units)

1.

Re-install / replace clamp spring

2.

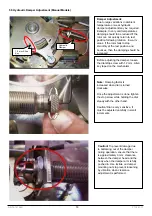

Adjust hydraulic damper (see 5.5)

1.

Adjust hydraulic damper (see 5.5)

2.

Replace and adjust hydraulic

damper