Manual

Version

Page

DB04A

EN A1-9

PKP Prozessmesstechnik

08

1.12. Instructions and warnings

Read all of the operating instructions thoroughly before installing and commissioning equipment.

Misconceptions and incorrect use can lead to breakage of the measuring device or risk of personal

injury.

The installation, commissioning and operation and maintenance must be done by appropriately

qualified personnel.

1.13. Documentation and cables supplied

Every unit comes with a USB A to USB Micro-B cable. This cable can be used to power the unit

and to upgrade the firmware.

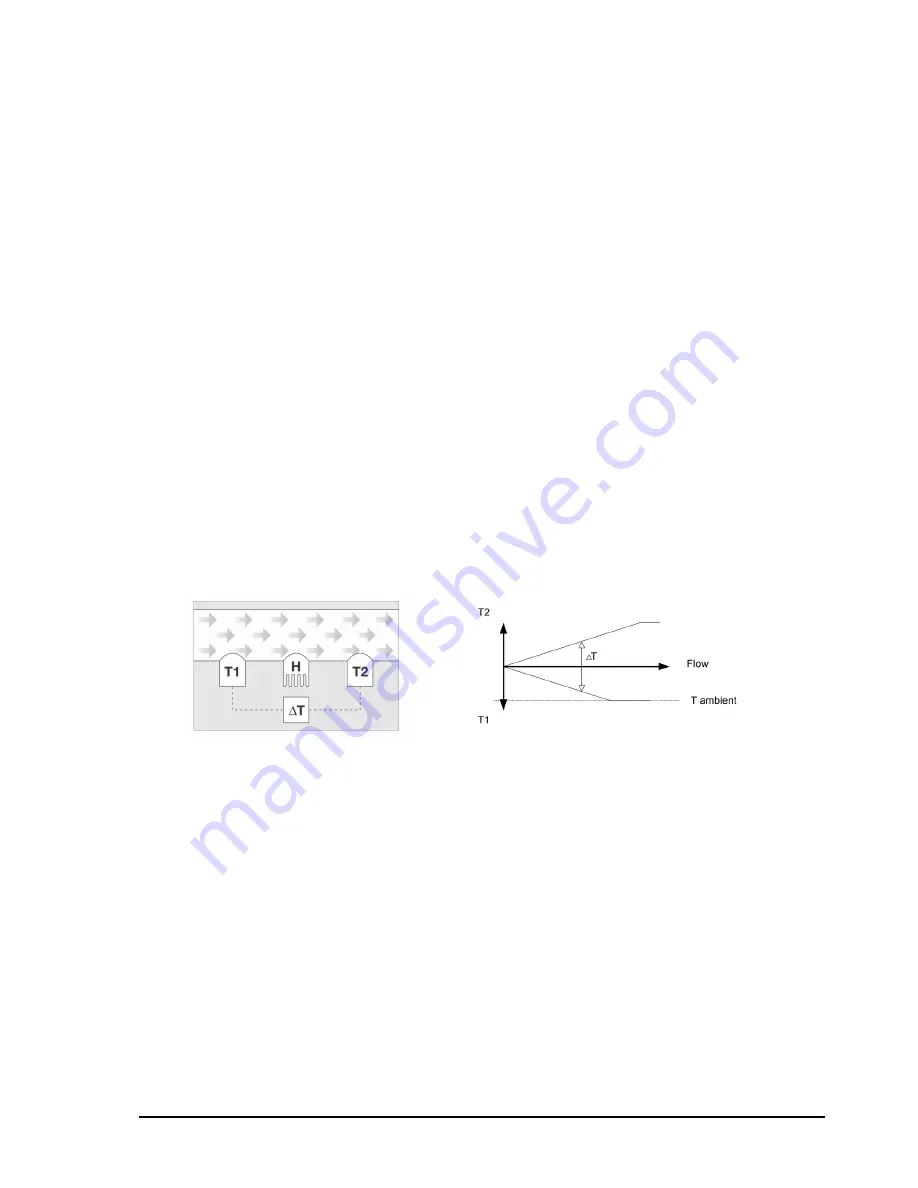

1.14. The measurement principle

The thermal mass flow measurement principle is particularly suitable for the measurement and

control of clean and dry gaseous media. The most significant advantage is that the measurement

process measures the real mass flow and is largely independent of temperature and pressure.

Stated simply, the thermal measurement principle measures the heat transport by gas flowing past.

In the case of

DB04A

mass flow measuring instruments, a constant heat input gives a flow-

dependent temperature difference (∆T). Two temperature sensors are positioned in the measuring

channel (T1, T2), one before the heating system (H) and one after it.

If there is no flow, the heat spreads symmetrically in directions T1 and T2. The temperature

difference T1-T2 is therefore zero.

Flow rates > 0 create a temperature difference.

The sensor T1 at the inlet is cooled by the gas flowing past it, and the temperature of the second

sensor T2 rises due to the heat drawn from the heating system.

T

he temperature difference is related non-lineary to the mass flow, with very high repeatability. The

electronics will, based on the calibration, convert this temperature difference in a linear and

proportional indication of the mass flow of the gas.

Figure 1: Measurement principle

Figure 2: Sensor operation