16. On your LC Dental, go to ‘MAIN’ screen, and

select ‘PRINT FILES’

off-line file transfer

17. If you need to transfer a new print file to your

Liquid Crystal Dental, copy it onto the USB flash

drive, then plug the drive into the USB port on the

front of the machine

18. Select ‘REFRESH’, your new print file should

appear

NOTE:

See section 5.2 for instructions on transferring

print files via a network connection.

5.3 PHOTOCENTRIC

STUDIO SETUP

A 16 GB USB flash drive is supplied with your

Liquid Crystal Dental. On this drive you can find

a license number for Photocentric Studio. This

allows you to activate a perpetual license for up

to two PCs.

Photocentric Studio can be downloaded from this

webpage:

h t t p s : / / p h o t o c e n t r i c g r o u p . u s / s u p p o r t -

photocentric-studio/

On this page, you can also find guidance on the

following:

The minimum system requirements for Photocentric

Studio

- Installing the software

- Getting started

- Adding supports and slicing files

- Updating the software

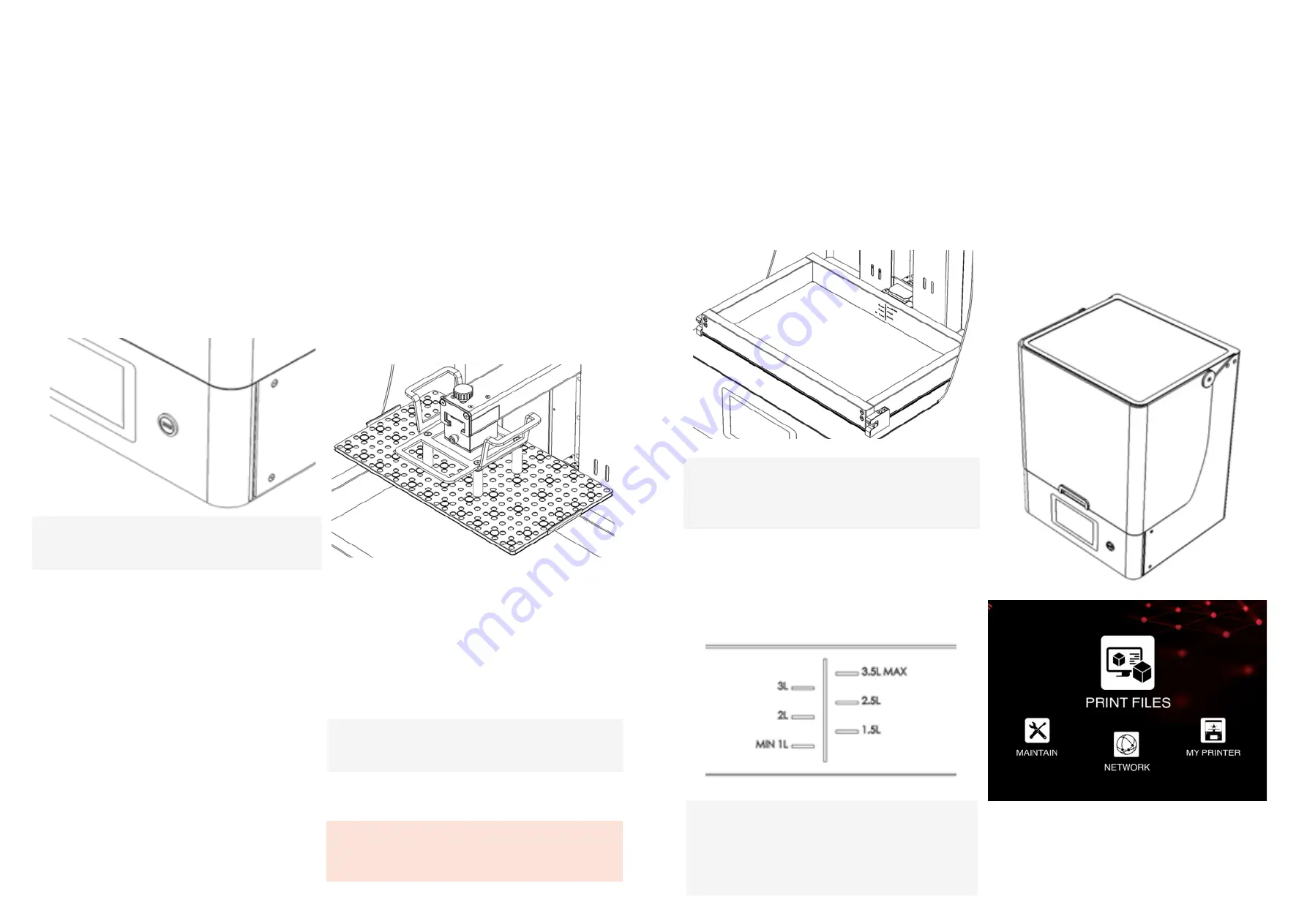

1. Ensure that your Liquid Crystal Dental is

positioned on a stable, level surface where it will

not be subject to movement or vibrations during

the printing process

2. Ensure that the print platform is completely clean

and dry, failure to do so may result in damage to

your vat film or a failed print

3. Load the print platform into the printer, you

should feel a positive click

4. Tighten the turn knob firmly to lock the print

platform in place

5. Ensure that the resin vat is completely clean and

dry to avoid print failures or damage

6. Check the vat film for signs of damage or wear, if

you have any doubt about the condition of the vat

film, refer to section 9.1

NOTE:

Printing with a damaged vat will cause failures and

leaks causing permanent damage to the printer

7. Load the resin vat into the printer, you should

feel a positive click

WARNING:

Photopolymer resin is an irritant. always wear

PPE. See Pg 4

8. Select the correct resin for the file you wish to

NOTE:

Correct resin is based on profile selected in

Photocentric Studio. If correct resin is not used the

print will fail.

9. Check the volume of resin required for the file

(Photocentric Studio will provide this figure), add

an extra 300 ml to make sure there is enough

10. Pour the resin into the vat, for smaller files top

up to a minimum of 1 litre

NOTE:

You can ensure your printer is level at this point by

pouring a small amount of resin into the vat and

checking that it sits in an even layer over the vat

film.

11. Close the printer hood, the icon in the top right

of the touchscreen should show a green closed

door

12. On the ‘MAIN’ screen, select ‘PRINT FILES’

13. ‘PRINT’

14. Your Liquid Crystal Dental will start the printing

process

6 PRINTING

8

7

DENTAL

Liquid Crystal

DENTAL

Liquid Crystal