GC7430

5-8

TRAY RUBBER CAP 30

TRAY ASSY 33

DOOR ASSY

Remove

TRAY RUBBER CAP 30 (3x)

Remove

Screw F1, F2, F3

Disassemble

TRAY ASSY 33

Remove

Screw G

Disassemble

DOOR ASSY

FRONT PANEL PRINTED 37

POWER BOARD 43

CONTROL BOARD

Remove

TRAY RUBBER CAP 30 (3x)

Remove

Screw F1, F2, F3

Disassemble

TRAY ASSY 33

Remove

Screw H1, H2

Disassemble

FRONT PANEL 37

Remove

Screw J1, J2

Disassemble

PCB BRACKET

Disassemble

CONTROL BOARD

Disassemble

POWER BOARD 43

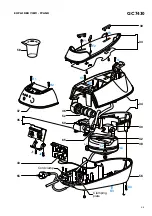

DISASSEMBLY ADVICE - STAND

WATER TANK ASSY 34

HOSE CORD CAP 36

BOILER ASSY 38

BRAIDED RUBBER HOSE -

BOILER

PUMP ASSY 45

INLET TUBE - PUMP

DE-AIR TUBE

RINSE RUBBER COUPLING 50

RINSE BUSH

RINSE CAP ASSY 52

Remove

TRAY RUBBER CAP 30 (3x)

Remove

Screw F1, F2, F3

Disassemble

TRAY ASSY 33

Remove

Screw H1, H2

Disassemble

FRONT PANEL 37

Disassemble

HOSE CORD CAP 36

Disassemble

RINSE CAP ASSY 52

Disassemble

RINSE BUSH

Disassemble

RINSE RUBBER COUPLING 50

Remove

Screws K1, K2, K3, K4

Disconnect

INLET TUBE - PUMP

Disconnect

DE-AIR TUBE

Disassemble

WATER TANK ASSY 34

Disassemble

BRAIDED RUBBER HOSE - BOILER

Disassemble

PUMP ASSY 45

Remove

Torx screws L1, L2, L3

Disassemble

TOP SPACER

Disassemble

BOILER ASSY 38

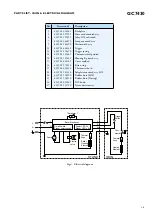

PARTS LIST - STAND

Note: For Pos 45, please replace both components together when either one is faulty.

The 2 components come as a service kit.

Pos

Service code

Description

30

33

34

36

37

38

40

42

43

45

4239 015 58701

4239 021 55751

4239 021 55711

4239 026 38361

4239 021 55691

4239 021 39540

4239 017 09890

4239 010 10260

4239 021 40360

4239 022 63002

Tray rubber cap

Tray B assy

Water tank assy

Hose cord cap

Front panel C printed assy

Boiler assy - High End

Electrovalve

Inox clamp

Power board

Control board-Pump assy kit

Pos

Service code

Description

50

52

55

56

58

65

4239 015 56760

4239 021 55671

4239 000 10080

4239 021 55661

4239 026 05990

4239 026 42081

Rinse rubber coupling

Rinse cap assy

Cord set EU

Stand bottom B assy

Filling cup

De-air valve

= changed