5-2

PL10.5EA

The White Balance Adjustment should be

performed when replacing the LCD Panel

or Digital Main CBA.

2. White Balance Adjustment

Purpose:

To mix red, green and blue beams correctly

for pure white.

Symptom of Misadjustment:

White becomes bluish

or reddish.

1. Operate the unit for more than 60 minutes.

2. Input the White Raster(70%=70IRE, 40%=40IRE).

3. Set the color analyzer at the CHROMA mode and

zero point calibration. Bring the optical receptor

pointing at the center of the LCD-Panel at a

distance of 1.18 inches(3cm) away from the LCD-

Panel surface.

Note:

The optical receptor must be set

perpendicularly to the LCD Panel surface.

4. Enter the Service mode. Press [VOLUME DOWN]

button on the remote control unit and select “C/D”

mode.

5.

[CUTOFF]

Press [1] button to select “COR” for Red Cutoff

adjustment. Press [3] button to select “COB” for

Blue Cutoff adjustment.

[DRIVE]

Press [4] button to select “DR” for Red Drive

adjustment. Press [6] button to select “DB” for Blue

Drive adjustment.

6. In each color mode, press [CHANNEL UP/DOWN]

buttons to adjust the values of color.

7. Adjust Cutoff and Drive so that the color

temperature becomes 12000°K (x= 0.272 / y=

0.278 ±0.005).

8. To cancel or to exit from the White Balance

Adjustment, press [PREV CH] button.

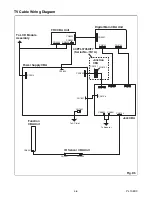

Test Point Adj. Point

Mode

Input

Screen

[VOLUME

DOWN]

button

[VIDEO1]

C/D

White Raster

(APL 70%)

or

(APL 40%)

M. EQ.

Spec.

Pattern Generator,

Color analyzer

x= 0.272 ± 0.005

y= 0.278 ± 0.005

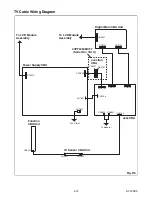

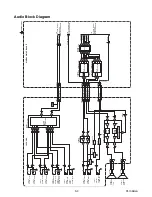

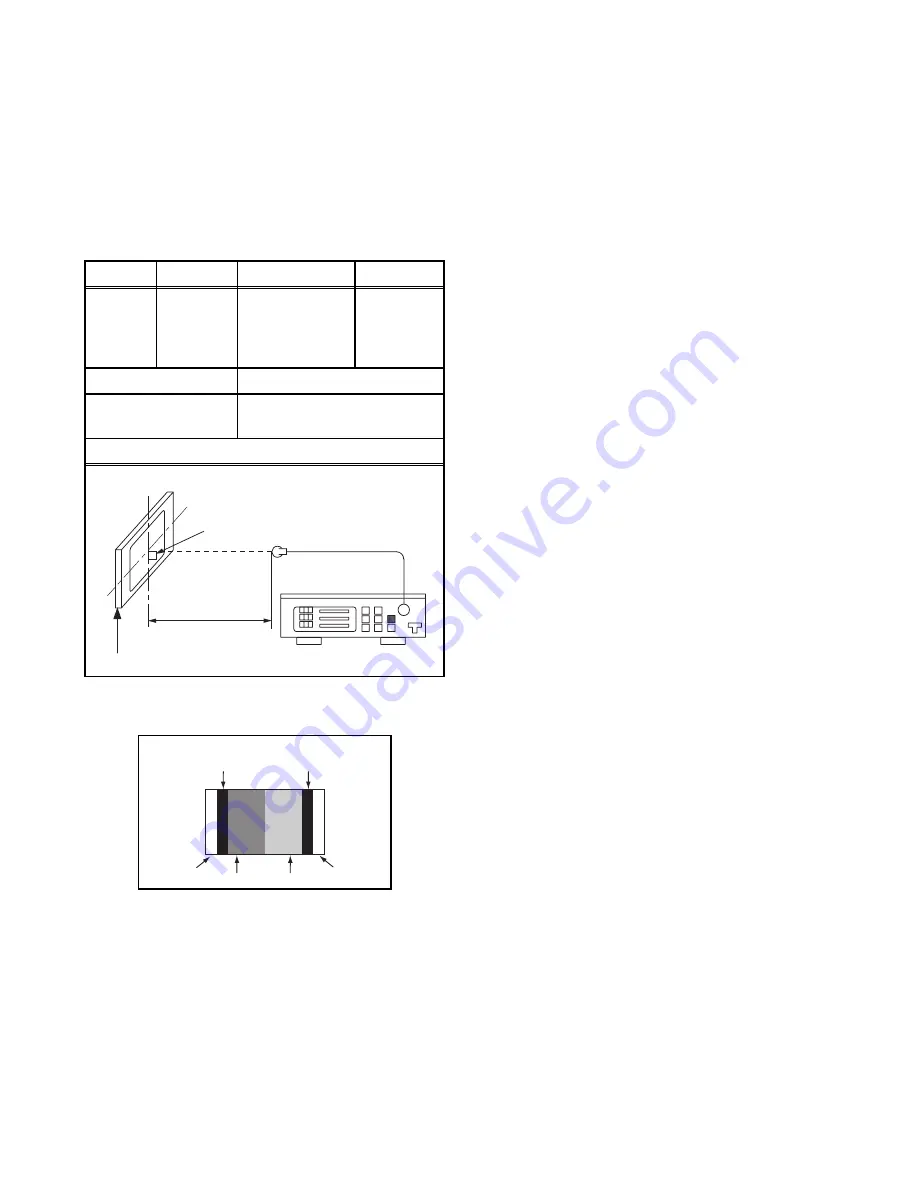

Figure

Color Analyzer

Perpendicularity

INPUT: WHITE 70%, 40%

To avoid interference from ambient

light, this adjustment should be

performed in a dark room.

L = 1.18 inches

40%=40IRE

70%=70IRE

100IRE

100IRE

0IRE

0IRE

INPUT SIGNAL

Low

Light

Hight

Light

Содержание 40PFL3505D/F7

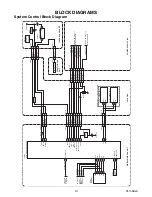

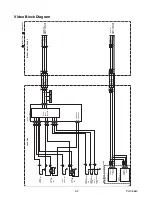

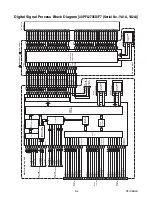

Страница 49: ...10 6 PL10 5SCJ1 Jack 1 Schematic Diagram ...

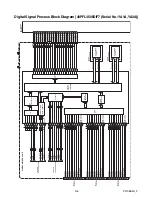

Страница 50: ...10 7 PL10 5SCJ2 Jack 2 Junction Schematic Diagram ...

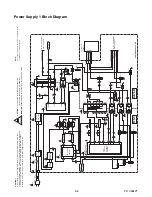

Страница 51: ...10 8 PL10 5SCF Function Schematic Diagram ...

Страница 52: ...10 9 PL10 5SCIR IR Sensor Schematic Diagram ...