12

6. Maintenance

Maintenance on the individual components of

the pumping station should be carried out in

accordance with the instructions in the

respective sections of the relevant operating

instructions.

6.1. Replacing The Lubricant Reservoir And

The Operating Fluid

– The d

diia

ap

ph

hrra

ag

gm

m p

pu

um

mp

p bearings are lubricated for the whole

of their working life.

– The lubricant reservoir in respect of the ttu

urrb

bo

op

pu

um

mp

p should

be replaced at least once a year. Where extreme

operating conditions or unclean processes are involved,

the replacement interval should be shorter.

Procedure:

➡

Unscrew the four screws from the cover plate and remove.

➡

Unscrew four screws from the turbopump holding plate.

➡

Lift out the turbopump with the holding plate from the

pumping station.

➡

Carry out the change of the lubricant reservoir in

accordance with the turbopump operating instructions.

The Lubricant can contain toxic substances

from the medium pumped. Lubricant must be

disposed of in accordance with the respective

regulations.

Safety instructions data sheet for the lubricant

on request.

– The operating fluid for the rro

otta

arryy vva

an

ne

e vva

ac

cu

uu

um

m p

pu

um

mp

p

should be changed at least once a year.

Procedure:

➡

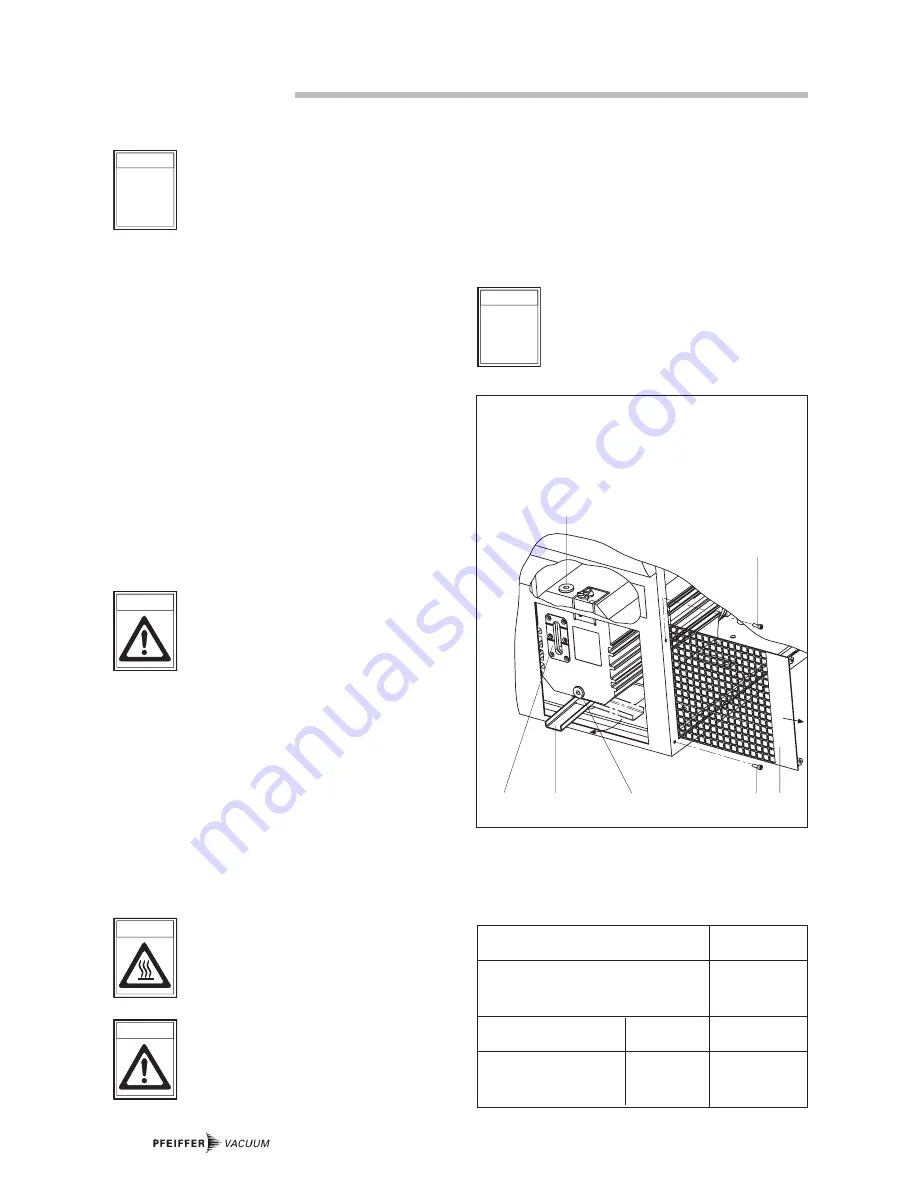

Unscrew the two screws on the right hand side panel.

Slightly lift up the side panel and remove.

➡

Unscrew two screws 4 and pull out perforated plate 5 to

the right hand side.

➡

Exert slight downward pressure on operating fluid duct 6,

turn 90° and bring into the forward position.

➡

Unscrew operating fluid drain screw 7 and drain operating

fluid via operating fluid duct 6 into a suitable container.

The temperature of the operating fluid can be as

high as 80 °C.

Toxic gases and vapours can escape from the

operating fluid which can be enriched with

substances which represent a hazard to health.

Disposal must be carried out in accordance with

the relevant regulations.

WARNING

WARNING

WARNING

☞

PLEASE NOTE

Lubricant reservoir

on turbomolecular pumps

Order number

TMH/U 071

PM 073 073 -T

TMH/U 261

PM 063 265-T

TMH/U 521

PM 063 265 -T

Operating fluid for rotary

vane vacuum pumps

Pack size

Order number

P3

1 l

PK 001 106 -T

P3

5 l

PK 001 107 -T

P3

20 l

PK 001 108 -T

4 5

7

6

9

4

8

Changing the operating fluid on rotary vane vacuum pumps

4

Screws (2 pieces)

5

Perforated plate

6

Operating fluid duct

7

Operating fluid drain screw

8

Operating fluid filler screw

9

Sight glass

Order numbers for the lubricant reservoir on turbopumps and

operating fluid on rotary vane vacuum pumps

➡

Screw back in operating fluid drain screw 7 taking care

with the O-ring.

➡

Fill in operating fluid as described in Section 4.1. of these

operating instructions.

➡

Re-fit the perforated plate and the side panel.

➡

Check the operating fluid daily where non-stop operations

are involved, otherwise each time the pumping station is

switched on.

Further information regarding changes of

operating fluid can be found in the operating

instructions for the respective rotary vane

vacuum pump.

☞

PLEASE NOTE