78

SEBU8455

Maintenance Section

Fan Clearance - Check

g02793699

Illustration 52

Typical example

The adjuster screw (1) must be torque to 27 N·m

(20 lb ft). After tightening the adjuster screw the valve

lash must be checked again.

Install the valve mechanism cover. For more

information refer to System Operation Testing and

Adjusting, “Engine Valve Lash -Inspect/Adjust”.

i04633518

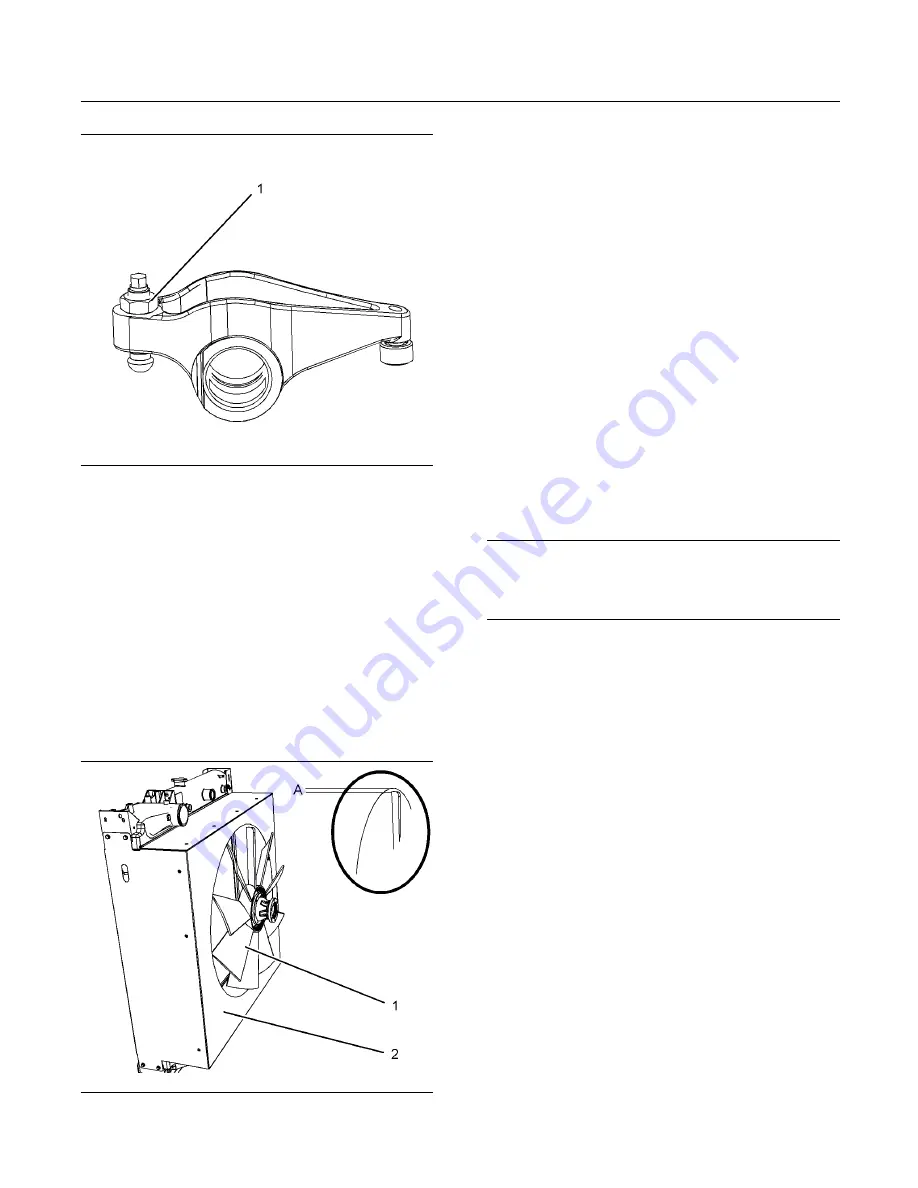

Fan Clearance - Check

g02778616

Illustration 53

Typical example

Ensure that the engine is stopped. Ensure that the

battery disconnect switch is in the OFF position.

Ensure that the cooling system is full. The clearance

between the cover (2) and the fan (1) will require

checking. The gap (A) between the cover and the

edge of the fan blade must be checked in

fi

ve equally

spaced positions.

Adjustment of the cover will change the clearance

gap between the cover and the edge of the fan

blade. Ensure that the cover is centralized to

the fan. The clearance (A) must be 21 ± 2 mm

(0.82677 ± 0.07874 inch).

i04272833

Fuel System - Prime

Ensure that all adjustments and repairs are performed

by authorized personnel that have had the correct

training.

NOTICE

Do not crank the engine continuously for more than

30 seconds. Allow the starting motor to cool for two

minutes before cranking the engine again.

If air enters the fuel system, the air must be purged

from the fuel system before the engine can be

started. Air can enter the fuel system when the

following events occur:

•

The fuel tank is empty or the fuel tank has been

partially drained.

•

The low-pressure fuel lines are disconnected.

•

A leak exists in the low-pressure fuel system.

•

The fuel

fi

lter has been replaced.

If you inspect the engine in operation, always use

the proper inspection procedure in order to avoid

a

fl

uid penetration hazard. Refer to Operation and

Maintenance Manual, “General hazard Information”.