SEBU8337

71

Maintenance Section

Engine Valve Lash - Inspect/Adjust

i02568163

Engine Valve Lash -

Inspect/Adjust

The initial valve lash adjustment on new engines,

rebuilt engines, or remanufactured engines is

recommended at the

fi

rst scheduled oil change. The

adjustment is necessary due to the initial wear of

the valve train components and to the seating of the

valve train components.

This maintenance is recommended by Perkins as

part of a lubrication and preventive maintenance

schedule in order to help provide maximum engine

life.

NOTICE

Only quali

fi

ed service personel should perform this

maintenance. Refer to the Service Manual or your au-

thorized Perkins dealer or your Perkins distributor for

the complete valve lash adjustment procedure.

Operation of Perkins engines with incorrect valve lash

can reduce engine ef

fi

ciency, and also reduce engine

component life.

Ensure that the engine can not be started while

this maintenance is being performed. To help pre-

vent possible injury, do not use the starting motor

to turn the

fl

ywheel.

Hot engine components can cause burns. Allow

additional time for the engine to cool before mea-

suring/adjusting valve lash clearance.

Ensure that the engine is stopped before measuring

the valve lash. To obtain an accurate measurement,

allow the valves to cool before this maintenance is

performed.

The following components should be inspected and

adjusted when the valves are inspected and adjusted.

•

Valve actuators

•

Injectors

Refer to Systems Operation, Testing and Adjusting,

“Engine Valve Lash - Inspect/Adjust” for more

information.

i02793537

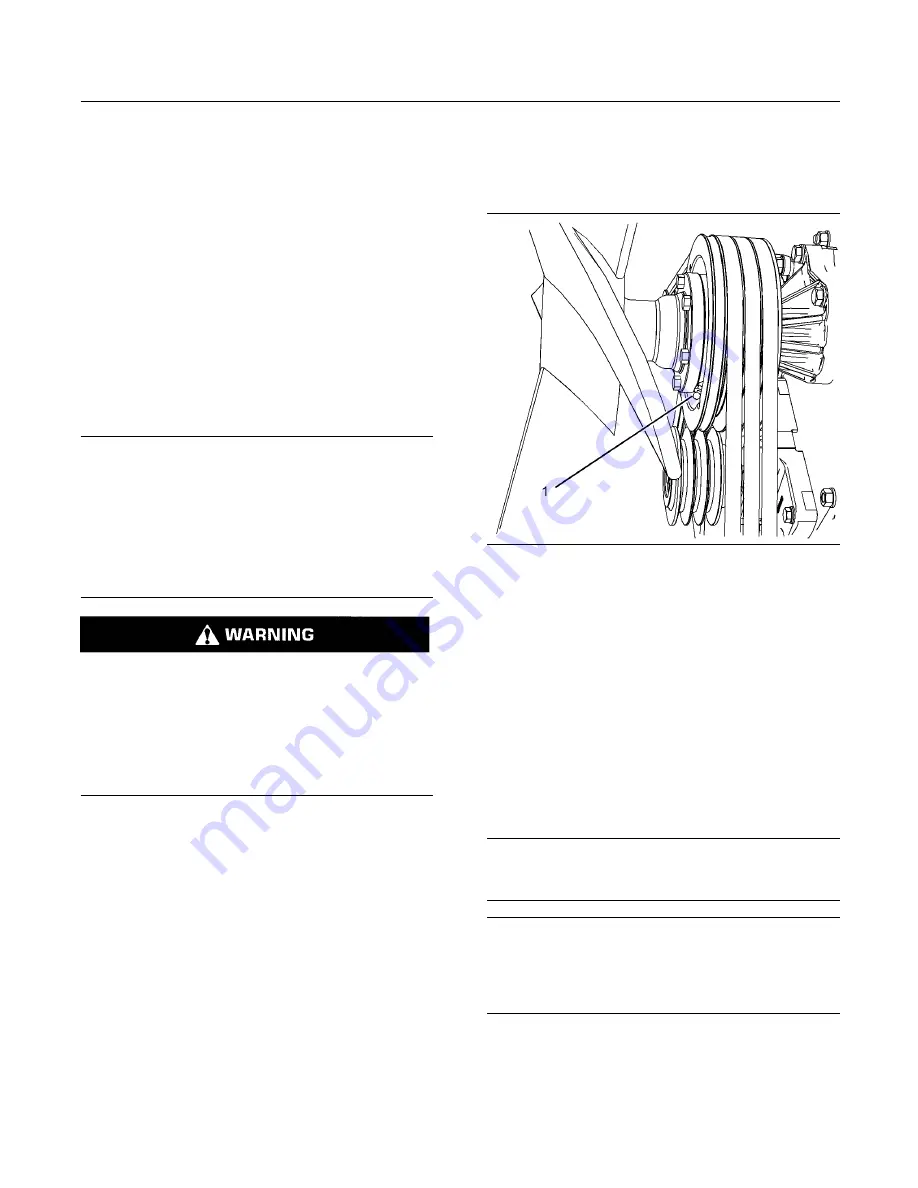

Fan Drive Bearing - Lubricate

g01395016

Illustration 39

Typical example

Inspect the fan drive pulley assembly for wear or for

damage. If the shaft is loose, an inspection of the

internal components should be performed. Refer to

the Service Manual for additional information.

Lubricate the grease

fi

tting (1) that is on the fan drive

bearing with

CV3080

Grease.

i02790862

Fuel System - Prime

NOTICE

Use a suitable container to catch any fuel that might

spill. Clean up any spilled fuel immediately.

NOTICE

Do not allow dirt to enter the fuel system. Thoroughly

clean the area around a fuel system component that

will be disconnected. Fit a suitable cover over discon-

nected fuel system component.

1.

Turn the ignition switch to the “OFF” position.

2.

Ensure that the fuel tank is full with clean diesel

fuel. Place a suitable container under the fuel

fi

lters in order to catch any split fuel.