4

ENGLISH

It must be ensured that all mains cables

from the submersible motorised aerator and

the pumps used are securely attached and

do not float in the wastewater. This will pre-

vent the rotating propeller from coming into

contact with the cables and damaging them.

The propeller itself is protected by a guide

ring on the housing.

Attachment of aeration hose (example)

Securely attach a 90° bend to the male

thread socket and then screw a hose nozzle

into the bend. The suction hose can now be

secured to the nozzle with a hose clamp.

ATTENTION!

If the pump is malfunction-

ing, a slight leakage of the contents of the

oil reservoir into the wastewater medium is

possible.

MAINTENANCE

Before carrying out any works:

disconnect the aerator and the

controls from the mains and take

steps to ensure that no one else can recon-

nect them to the power supply.

Check the mains cable for me-

chanical or chemical damage. A

damaged or kinked cable must be

replaced.

When using a chain to lift the aera-

tor, please observe the relevant

national regulations regarding ac-

cident prevention.

Remove any solids and fibres from the aerator

housing and the aeration propeller. To main-

tain the function of the cooling surfaces, they

must be cleaned regularly to remove any resi-

dues (e.g. limescale).

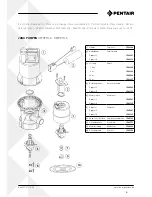

Replacing the propeller

ATTENTION!

In some models, there is a spe-

cial shim disc between the motor shaft and

the propeller. This must also be re-inserted

after the propeller has been replaced.

The propeller is attached to the motor shaft

with a cylinder head screw. This screw must

first of all be removed using an Allen key, and

then the propeller can be carefully taken off

the motor shaft and replaced.

The propeller must not rub against the hous-

ing once it has been tightened, otherwise a

shim must be inserted between the housing

and the propeller.

ATTENTION!

The gap between the housing

and the propeller must not be greater than

1 mm, as otherwise the mechanical seal

on the OXYPERL will not be sufficiently pre-

stressed and oil leaks may occur.

Tightening torque M

A

of the screws

M 6 with M

A

= 5 Nm, Amtec 3.5 with M

A

= 1 Nm

and Amtec 5.0 with M

A

= 2 Nm.

Air reflux valve (Accessory)

A particularly for problematic cases de-

veloped optional air reflux valve presents a

pressure compensation when switching off

the aggregate. This also ensures that no sol-

ids get into the propeller.

Quick tips for remedying

faults

OXYPERL is not working

∙ Check mains current (do not use a pin

gauge)

∙ Fuse faulty = may be too weak (please

refer to the section entitled Electrical

connection)

∙ Mains cable damaged = replace cable

∙ The cooling surfaces are not completely

submersed or are soiled and the electric

motor has overheated and cut out = wait

for a while and the OXYPERL will start

up again automatically (clean the cool-

ing surfaces and check the installation

dimensions).

Reduced air insertion

∙ Ensure that the air ducts in the aeration

propeller are not clogged. If necessary,

flush any solids out.

∙ Check that there are no obstructions in

the suction hose.

Reduced circulation performance

∙ Propeller is rubbing against the aerator

housing

1. The propeller is resting loosely on the

motor shaft = tighten the cylinder head

screw.

2. Solids are caught between the propeller

and the aerator housing = loosen the cyl-

inder head screw and lift the propeller off

the motor shaft. Clean the parts and screw

all parts on again tightly.

3. The gap between the propeller and the

housing is too small and the original st

ate cannot be restored = insert a special

shim disc (mat. no. 41957) between the

shaft and the propeller

∙ The propeller is damaged or worn =

replace

Power input too high

∙ The gap between the propeller and the

housing is too small and the original

state cannot be restored = insert a

special shim disc between the shaft and

the propeller.

TECHNICAL DATA

OXYPERL

3 /2

OXYPERL

5 /1

[kg]

4

5

[mm]

32

40

P1

[W]

310

540

P2

[W]

210

390

U

[V]

1/N/PE ~230 1/N/PE ~230

f

[Hz]

50

50

I

[A]

1,37

2,36

n

[min

-1

] 2765

2700

Содержание oxyperl 3

Страница 1: ...B 44665 21 1403 www jung pumpen de EN Instruction Manual JUNG PUMPEN OXYPERL ...

Страница 7: ...7 ...