5

required), the cord cap should be re-

attached reversing the steps above.

Ensure the o-ring is in place and

perform a hi-pot test for safety once

everything is complete.

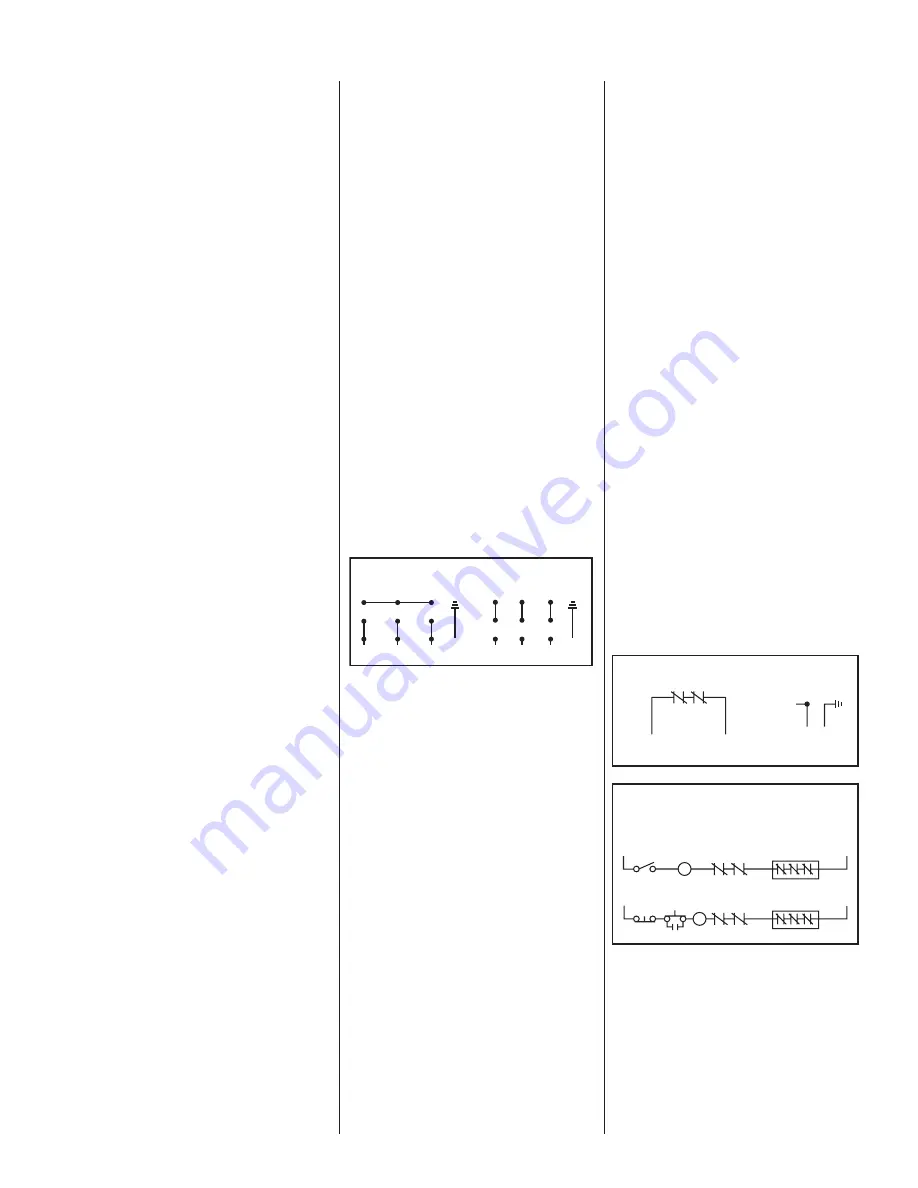

Heat Sensors and Seal Failure

Connections:

Be sure heat sensor wires are

con nect ed in series with the starter

coil. Connections are provided on

the terminal strip.

If seal failure unit is used, connect

as shown with seal failure system. If

seal failure unit is not used, the two

seal failure wires are left open.

Do not connect power to these lines

at any time.

Pump Operations

Starting System:

1. Turn H-O-A switch to Off

position and then turn on

main circuit breakers.

2. Open all discharge valves and

allow water to rise in sump.

3. Turn H-O-A switch to Hand

position on one pump and

notice operation. If pump is

noisy and vibrates, rotation

is wrong. To change rotation,

interchange any two line

leads to motor 3ø only. Do not

interchange main incoming

lines. If duplex system,

check second pump in the

same manner.

4. Now set both H-O-A switches

to Auto position and allow

water to rise in sump until one

pump starts. Allow pump to

op er ate until level drops to

turnoff point.

5. Allow sump level to rise to

start other pump. Notice run

lights on panel. Pumps should

alternate on each successive

cycle of op er a tion.

6. Turn both H-O-A switches

to Off position and allow

sump to fill to the override

control level.

7. Turn both switches to Auto

po si tion and both pumps

should start and operate

together until level drops to

turnoff point.

8. Repeat this operation cycle

sev er al times before leaving

the job.

9. Check voltage when pumps

are operating and check the

amp draw of each pump.

Check amps on each wire,

as sometimes a high leg

will exist. One leg can be

somewhat higher (5 to 10%)

without causing trouble.

For excessive amp draw on

one leg, the power company

should be con sult ed.

Phase Converters:

Phase converters are generally

not recommended, but in cases

where only single phase current

is available, phase converters can

be used. Be sure to size the phase

converter large enough for the

amp draw specified on the motor

nameplate, not necessarily by motor

horsepower. The warranty on all

three phase submersible motors is

void if operated with single phase

power through a phase converter,

and 3 leg ambient compensated

extra quick trip overload protectors

are not used.

Pump Maintenance

Lubrication or other maintenance

is not required, as the motors are

oil filled.

If a seal failure unit is used, no at ten-

tion is necessary as long as the seal

shows satisfactory operation.

If seal failure is not used, the pump

should be lifted once every two years

and the oil drained from the seal

chamber to check for water.

Lightning:

In some areas where considerable

lightning occurs, it is recommended

that a lightning arrestor be installed

at the control panel. Lightning

arrestors are good insurance against

damage to an expensive motor.

Field Service on Motor:

All submersible motors out of

warranty can be serviced in the

field by any reliable motor service

shop. Any pump (in warranty) must

be returned to the factory for

service or re paired at an authorized

Hydromatic

®

service center. Charges

will not be allowed if (in warranty)

pump is not taken to an authorized

Hydromatic service center.

When field service is performed on a

pump, these instructions should be

carefully followed.

Field Service on Hydromatic

®

Hazardous Location Pumps:

If a Hydromatic hazardous location

pump is used in a hazardous

location, or if the pump is still in war-

ran ty, the pump must be returned to

the factory for service or repaired

DUAL VOLTAGE

3 PHASE MOTOR WIRING

230V 3ø

460V 3ø

GREEN

GREEN

R

(L3)

W

(L2)

BL

(L1)

R

(L3)

W

(L2)

BL

(L1)

1

2

3

7

8

9

4

5

6

1

2

3

7

8

9

4

5

6

HEAT SENSORS AND SEAL FAILURE CONNECTIONS

FOR ANY VOLTAGE MOTOR

ELECTRODE

HEAT SENSORS

IN MOTOR

WINDINGS

WHITE

BLACK

HEAT SENSORS

SEAL FAILURE

RED

DARK

GREEN

WARNING

BLACK

COIL

ON-OFF

SWITCH

L1

THERMOSTATS

IN SERIES

WHITE

L2

TWO WIRE CONTROL OFFERING AUTOMATIC RESET

THERMOSTATS

IN SERIES

WHITE

L2

BLACK

THREE WIRE CONTROL OFFERING AUTOMATIC RESET

L1

COIL OL

OL

START

IN CERTAIN APPLICATIONS THE NEC MAY REQUIRE THREE OVERLOAD RELAYS

WARRANTY IS VOID IF HEAT SENSORS ARE NOT

CONNECTED AS SHOWN (IN SERIES WITH CONTACTOR OIL)

Содержание S3R

Страница 9: ...9 Wiring Diagrams...