8

E-03-601 (02-15-22)

MAKING ELECTRICAL CONNECTIONS

ElECTROCUTION HAZARD:

Must be

installed by a qualified professional. Disconnect all electrical

power before installation or servicing the pump.

All electrical wiring must be in accordance with local codes,

and only competent electricians should make the installations.

Complete wiring diagrams are glued to the inside cover of the

panel. It is VERY IMPORTANT to check all wires for grounds with

an ohmmeter or Megger meter after the connections are made

as one grounded wire can cause considerable trouble

.

NOTICE

FM rated models are only to be used in

60hz applications.

NOTICE

If equipment is not properly wired and protected as

recommended, the warranty is void.

The 230 volt 3 phase pump has a dual marked

nameplate. For ordinary location pumps, voltage may be rewired

by qualified personnel. For hazardous location pumps, voltage

may be rewired by the manufacturer or a Class I, Div I equipment

qualified electrician. Once the voltage is changed, the factory

cord tag indicating 230 volt 3 phase must be removed.

For record keeping purposes, we suggest the pump be marked

externally with the new voltage and qualified personnel that

performed the change. Pumps shipped from the factory as 460

volt 3 phase cannot be rewired to any other voltage.

TO RE-WIRE THE PUMP FROM 230V TO 460V 3 PHASE

Only a 230V pump from the factory is considered dual voltage, a

cord label clearly states the factory wound voltage.

1. Remove all six (#7) cap screws then raise the cord cap

assembly enough to slip a prying instrument on opposite

sides between the cord cap casting and the motor housing.

Take care to not damage the o-ring or the machined

surfaces of the castings. Doing so could void FM agency

certifications.

2. While prying evenly on both sides; separate the cord cap

casting from the motor housing, the assembly is airtight

and will have a vacuum effect when disassembling.

3. Once separated, the cord cap can be inverted and rotated

to the outside of the pump assembly, and a bolt can be

re-used to secure the upside down cord cap to the motor

housing for ease of rewiring.

Refer to the wiring diagram within this manual for wiring

details. Once all electrical connections are finished and secure

(a crimped electrical connector is best to prevent issues due

to vibration if required), the cord cap should be re-attached

reversing the steps above. Ensure the o-ring is in place and

perform a hi-pot test for safety once everything is complete.

HEAT SENSORS AND SEAL FAILURE CONNECTIONS

Be sure heat sensor wires are connected in series with the starter

coil. Connections are provided on the terminal strip.

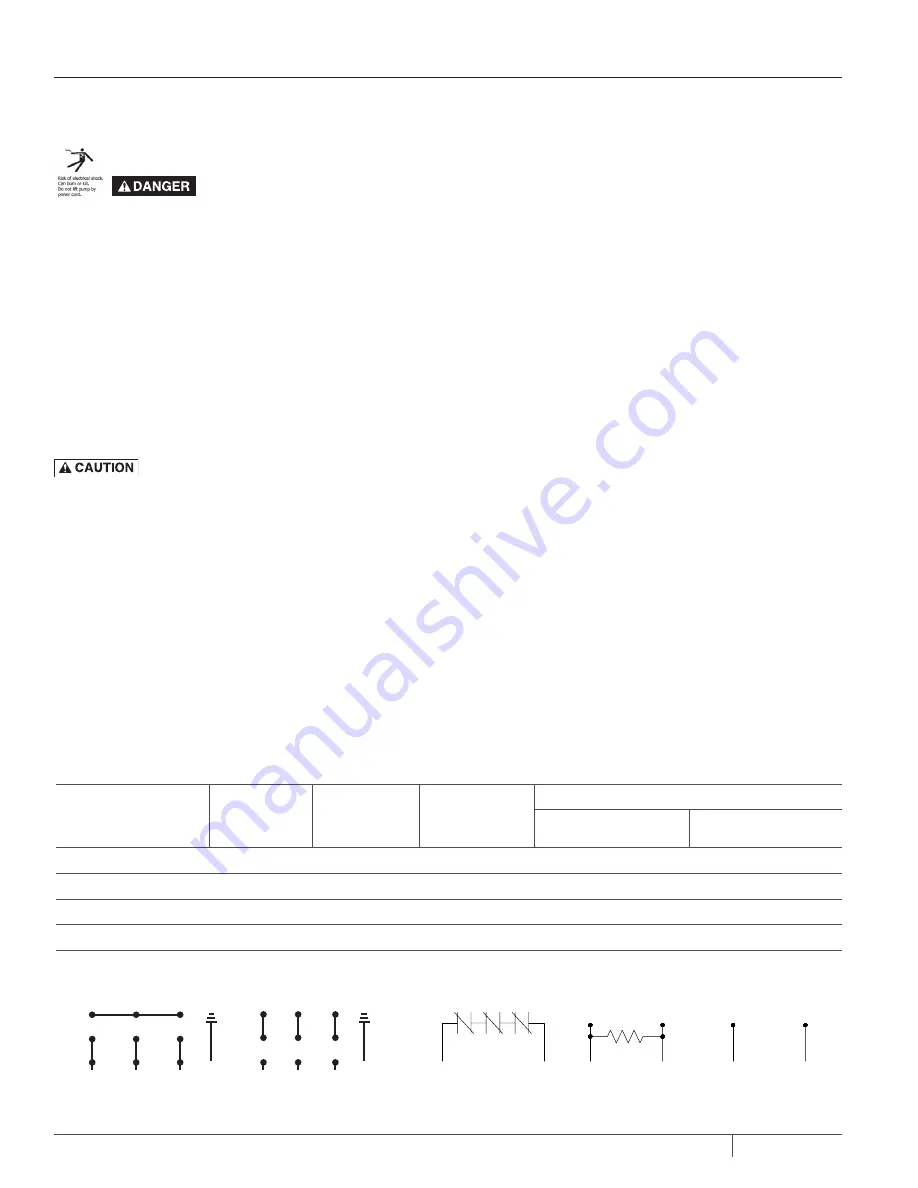

DUAL VOLTAGE

3 PHASE MOTOR WIRING

230V 3ø

460V 3ø

GREEN

GREEN

R

(L3)

W

(L2)

BL

(L1)

R

(L3)

W

(L2)

BL

(L1)

1

2

3

7

8

9

4

5

6

1

2

3

7

8

9

4

5

6

INSTALLATION

SYSTEM TYPE

NUMBER OF

CONTROL WIRES

NUMBER OF

POWER LINES

NUMBER OF

GROUND WIRES #8

HEAT SENSOR & SEAL FAILURE

NUMBER OF SENSOR

WIRES

NUMBER OF GROUND

WIRES

Simplex

4

3

1

3

1

Simplex with Alarm

6

3

1

3

1

Duplex

6

6

2

6

2

Duplex with Alarm

8

6

2

6

2

NUMBER OF CONDUCTORS REQUIRED BETWEEN CONTROL PANEL AND NEMA 4 JUNCTION BOX

Power lines and control wires can be carried in conduit or can be underground buried cable

HEAT SENSORS

IN MOTOR WINDINGS

BLACK

WHITE

MOTOR HEAT SENSORS

ELECTRODE

ELECTRODE

RED

ORANGE

330KΩ

HAZARDOUS RATED ONLY

SEAL FAILURE

ELECTRODE

ELECTRODE

RED

ORANGE

NON-HAZARDOUS RATED ONLY

SEAL FAILURE

HEAT SENSORS AND SEAL FAILURE CONNECTIONS

FOR ANY VOLTAGE MOTOR

Содержание HPS4HDX

Страница 3: ...3 E 03 601 02 15 22 PAGE INTENTIONALLY LEFT BLANK ...

Страница 17: ...17 E 03 601 02 15 22 WIRINGDIAGRAMS ...

Страница 18: ...18 E 03 601 02 15 22 WIRINGDIAGRAMS ...