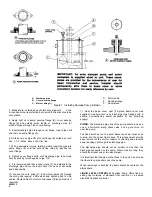

Figure 4. Single Phase Wiring Diagram, C84A or

C93A Float Controls

NOTES:

1. Float Control must be wired in series with P1 & P2 and set to open circuit

when liquid level drops no lower than minimums shown on pump dimension

drawings.

2. Connect to A.C. supply line of voltage required. All wiring must be in

accordance with N.E.C. and/or local electrical codes.

3. Connect terminals

7 & 8

to remote alarm device (by others). Terminals

5 & 6

can be wired in series with float control to shut pump down if moisture is

detected.

4. Combined length of control circuit leads and control wiring to moisture

detection control must not exceed 100 feet.

5. Motors are furnished by factory with motor leads connected for specifies

voltage. If it is necessary for voltage to be changed in the field reconnect

terminals in motor terminal head in accordance with conversion

diagrams. Splices must be watertight (see motor instructions for further

information).

6. The motor warranty is valid only if moisture detection and thermal protection

system is connected and operable. Failure to utilize these voids warranty.

7. Connections to motor starter and disconnect switch are typical only. All

equipment furnished by others is to be in accordance with N.E.C. and/or

local electrical codes.

Figure 5. Three Phase Wiring Diagram, C84A or

C93A Float Controls

8

2899213

Содержание UWLLB3

Страница 6: ...Figure 3 Installation Dimensions 6 2899213 ...

Страница 11: ...Figure 9 Type UW Sewage Pump 11 2899213 ...