IMPORTANT SAFETY PRECAUTIONS

Pump parts, and the tools and rigging equipment

used in installation, are heavy and may easily cause

personal injury if dropped or carelessly handled. The

normal precautions and safety rules associated with

the erection of heavy machinery, in regard to manual

lifting, use of power equipment, and handling of

tools, must be observed in the installation of this

pump.

Petroleum-base cleaning solvents are flammable.

Open flame or smoking by personnel in the vicinity

of these solvents is extremely hazardous and must

not be permitted.

Do not work under a suspended object unless there

is a positive support under it to stop its fall in event

of sling or hoist failure. Disregard of this warning

could result in grave personal injury.

Before attempting repairs to pump open the

disconnect switch to electric motor. This prevents

accidental running of pump motor. Starting motor

during pump repair activities could damage

pump

The pumps described in this bulletin must not be

installed in any manner except as specified herein,

and must not be operated at speeds, capacities,

pressures, or temperatures other than those for

which this specific model was originally designed. If

unsure or unknown, request this information from

Peerless Pump, giving the pump serial number as

reference.

Units are designed for continuous duty submerged

in liquids containing a maximum solid content 10%

by weight to 90% liquid normally encountered in

sewage lift or sump pump applications and limited

to corrosion limits of standard materials of construc-

tion. 40 dC [105dF] maximum liquid temperature.

Motors less than 1 hp. Labeled CI. 1 Group D are

supplied with a cautionary nameplate and are

suitable only when vapor or gas ignition tempera-

tures are 280dC or greater

.

UPON RECEIPT OF SEWAGE PUMP:

Check carefully

to see that all of the equipment has been received.

Report immediately any shortages or damages to the

transportation

company

handling

the

shipment,

noting the extent of the damage or shortage on the

freight bill and bill of lading. Do not leave the unit

exposed to weather or construction hazards. The

pump may become mechanically damaged. This

pump is a well designed and carefully manufactured

and may cause personal injury.

Disconnect power supply before attempting to

change connections in the starter. There is danger

of fatal electrical shock when working with

energized connections.

Disconnect the power supply before removing the

motor connection chamber to change connection.

There is danger of fatal electrical shock when

working with energized leads.

Do not use motor electrical cable to lift or lower

sewage pump. Use the pump lugs provided to attach

sling or cable for lifting and lowering pump into

basin. Electrical cable strains may cause equipment

malfunction, damage, and personal injury or death.

Tie the disconnect switch open or remove fuses

from lines before attempting to remove pump from

the basin. Attach a card “DO NOT CLOSE SWITCH-

PUMP REPAIR IN PROGRESS.” Disregard of this

warning may result in fatal electrical shock

.

WARNING

All units must be provided with a magnetic

across-the-line motor starter. The motor thermal

protector must be wired in series with the pump

liquid level controller and starter contactor holding

coil for motor warranty to be valid.

The motor thermal protectors are limited to control

circuits in which the maximum current does not

exceed the following values.

Volts Amps Inrush Amps

110-220 3.00 30.0

220-240 1.50 15.0

440-480 .75 7.5

575 .60 6.0

Violation of this warning will void the warranty and

may result in serious property damage or grave

personal injury.

INTRODUCTION

unit. It should be given the same attention accorded

to any precision machine.

The satisfactory operation of a pump depends to a

large extent upon proper installation. These instruct-

tions cannot answer every question that may arise as

each installation will be different. The installer and

the operator of this equipment must use good

judgment to adapt these procedures to the installation.

2

2899213

Содержание UWLLB3

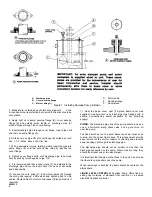

Страница 6: ...Figure 3 Installation Dimensions 6 2899213 ...

Страница 11: ...Figure 9 Type UW Sewage Pump 11 2899213 ...