OPERATION

BEFORE STARTING, CHECK THE FOLLOWING

ITEMS:

1. See that voltage and frequency on motor

nameplate are the same as service provided.

2. If motors are of the dual voltage type, be sure

motor leads are wired for the voltage used.

3. See that the proper fuses are installed.

4. See that switches are regulated for operation and

that thermal units are “set.”

STARTING:

Close the discharge gate valve and the

motor disconnect switch. The pump will not operate

unless the liquid level pilot circuit is closed. If a

selector switch is used, the pump may be run

independent of automatic controls by turning it to

“on” or manual position.

Read the list of important

Safety Precautions provided near

the front of this bulletin. The safety steps in that list

must be applied during maintenance procedures.

Failure to do so may lead to severe equipment

damage and personal injury or death.

TROUBLESHOOTING:

The following troubles may

occur. To correct trouble check for the possible

causes given.

1. Pump Fails to Operate:

a. A blown fuse, tripped or loose thermal unit.

b. Shaft binding or impeller blocked.

c. Switch contacts corroded, circuit shorted, or

terminal connections broken somewhere in circuit.

d. Pump control mechanism not functioning, or float

waterlogged.

e. Wiring hook-up or service provided incorrect, or

switches not “set” for operation.

f. Motor grounded or burned.

g. Electric service of phase failure.

h. Float rod buttons improperly adjusted or slipping.

2. Blown Fuse, Tripped Thermal Unit:

a. Fuse of thermal unit used of incorrect rating.

b. Shaft stuck or not rotating freely.

c. Loose connection somewhere in circuit.

d. Controls won of arcing.

e. Motor grounded or partially burned out.

f. Motor overloading.

g. Fuse or thermal unit location too hot.

h. Short circuit in wiring.

i. Discharge head is lower than anticipated.

3. Pump Runs Continuously:

a. Check pump rotation.

b. See if check valve in discharge line is stuck.

AFTER STARTING:

Note the following:

1. Slowly open the discharge gate valve.

2. Note operation of the control mechanism. Observe

several complete start-stop cycles of the unit. See

that pump control switch contacts close and open

properly as basin fills and is emptied by the pump.

The operation of the unit should be absolutely

automatic.

3. See that all pipe connections are tight.

4. Observe operation of pump closely for the first

day and at regular intervals for ten days. A new

machine is frequently stiff and tight, and therefore

the unit should be watched to note performance.

MAINTENANCE

c. Check discharge head, see if beyond pump rating.

WARNING

d. Check influent rate to basin; see if inflow is

excessive.

e. See if shaft in intact and if the impeller rotates.

f. Check to see if pump is air bound.

g. Check float and float switch assembly.

Tie the disconnect switch open

or

remove

fuses

from

lines

before attempting to remove pump from the basin.

Attach a card “DO NOT CLOSE SWITCH-PUMP

REPAIR IN PROGRESS.” Disregard of this warning

may result in fatal electrical shock.

WARNING

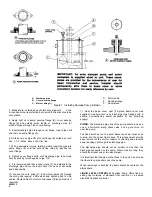

REMOVAL:

Remove the sewage pump in the

following manner (see figure 1):

1. Shut off or blank the influent line.

2. Close the gate valve in the discharge line.

3. Open the disconnect switch at power supply. Tie

switch open and attach card to prevent closing

accidentally.

4. Remove spool piece (F).

5. Loosen bolts of cover packing flange (B).

6. With an upward, twisting motion pull discharge

pipe (A) from the pump flange (E) to give clearance

for moving pump.

7. Tighten cover flange bolts to hold discharge pipe.

8. Tag leads for connection at reinstallation and

disconnect motor cables. Loosen motor cable grips

(C) and pull motor cables from cover.

9. Attach cable or sling to pump lugs and lift pump

from basin with a hoist of proper capacity.

7

2899213

Содержание UWLLB3

Страница 6: ...Figure 3 Installation Dimensions 6 2899213 ...

Страница 11: ...Figure 9 Type UW Sewage Pump 11 2899213 ...