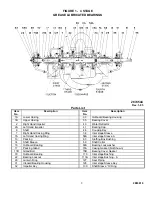

SECTION III

REASSEMBLY

3-1.

ROTATING ELEMENT.

(See Figure 7 or 8). Re-

assemble as follows:

a. Coat shaft (6) with oil. Re-oil as necessary while

pressing on impellers and sleeves.

b. With grooves, square shoulder side, facing toward the

highest number stage, press inter stage sleeve (58) or

balancing disc (56) on shaft. Insert hey (128) and locate

sleeve in the center of impeller section over square key

(128); disc to engage Woodruff key (32) between fourth

and fifth stages.

c. Insert key (32), align fifth(or fourth) stage impeller

(2 or 2A) and press on outboard (inboard) end of shaft to

contact disc (56) (sleeve 58).

d. Install casing ring A (7A), or inter stage bushing (113),

insert key (32) and press on fourth (or third) stage

impeller (2 or 2A).

e. Locate casing rings (7, 7A) on impellers.

f. Position inter stage sleeves A (58A) so that grooves

will be closer to lower number stages and press on shaft

to contact impeller hubs.

g. Install inter stage bushings A (113A) over sleeves

(58A) with beveled ends toward higher stages.

h. In turn, insert remaining keys (32), align impellers in

descending order of stages and press on shaft. Install

inter stage sleeves and bushings, and casing rings

between impeller stages. Carefully bump parts to

remove all clearance so that first and second stage

impeller hubs extend equally beyond central portion of

shaft (slightly into threaded portions).

i. Install O-rings shaft sleeves (14), coat ring and shaft

with oil and screw sleeves on shaft against impeller

hubs.

j. Install the stuffing box bushing (63) and lantern ring

(29) (not used on 5-stage pumps) on the shaft.

k. Locate casing rings (7) on lowest stage impellers;

install gland flanges (17D).

l. Place water detectors (40) on shaft.

m. Slide bearing covers (35) (with oil seals (107)

installed for oil lubricated bearings) on the shaft.

n. Place shaft collars (68) on the shaft.

o. Mount the bearings (16) and (18) as described in

Figure No. 4. The outboard bearings are two single row

angular contact bearings mounted in the duplex DB

mounting.

p. Install bearing lock washer (69A) and locknut (22) (oil

thrower) and tighten against the outboard bearing.

q. Install gaskets (73B) on bearing covers. Cut

replacement gaskets from 1/16 inch No. 444 Vellumoid.

r. Slide the housings (31, 33) over the bearings. Tap

lightly and evenly around the end as necessary. Do not

force.

s. Attach the bearing covers (35). In the assembled

position, the grease fittings or breather tubes must be

located on top.

t. Locate water deflector (40) and tighten the setscrews.

Install oil seal (107) in the inboard bearing housing (31)

(for oil lubricated bearings).

u. Install coupling key; assemble coupling half on the

shaft and tighten the setscrew.

3-2.

PUMP

. Complete the assembly of pump as follows:

a. Use the upper casing (1B) as a template to cut a

gasket (73A) from 1/64 inch Vellumoid. Machined

surfaces of both casings must be perfectly clean and

free from burrs and nicks.

b. Affix the new gasket to lower casing (1A) with shellac.

c. Use slings around the shaft near bearings to set

rotating element into lower casing. Position the casing

rings (7, 7A), inter stage bushing (113) and both bearing

housings so that all dowel pins engage. If necessary,

loosen setscrews of water deflector to shift bearing

housings slightly. Retighten screws.

d. Assemble both bearing caps (41) and tighten the cap

screws.

e. If impellers are not (approximately) centered in volute

or impellers are not allowing case rings to seat in casing,

adjust sleeves by loosening one and tightening the other

in direction required. Tighten setscrews in sleeve after

final adjustment is made.

f. Cover the top side of the casing gasket with a mixture

of graphite and oil. Install the gland bolts. Carefully

locate the upper casing on the lower (17B), making

certain the dowel pins engage. Attach case nuts and

alternately tighten at diagonally opposite positions.

Rotate shaft by hand to check that it runs free. See

Torque Chart, Table II.

g. Withdraw the lantern rings (29) (not used on 5-stage).

9

2883819