3.2 CONFIGURATION SWITCHES SW1 - SW8

This section provides detailed information about the function of

each DIP switch and lists all possible settings.

Switch 1: Hardware/Software Control/BERT Direction

The setting for Switch 1 determines whether the 2036P uses hard-

ware or software (i.e. XON/XOFF) flow control. Switch 1 is alternative-

ly used to determine the direction of the BERT output message when-

ever the BERT is activated (See Switch 2, below).

Switch 2: Bit Error Rate Test (BERT)

Use Switch 2 to activate a Bit Error Rate Test (BERT) in the direc-

tion of the serial

or parallel interface. This test can be used to deter-

mine whether the 2036P is working properly. When BERT is activated,

the 2036P outputs the following Barber Pole pattern, which represents

every ASCII character on a standard US keyboard:

0123456789:;<=>?@ABCDEFGHIJKLMNOPQRSTUVWXYZ[\}^_’abcdefghijklmnopqrstuvwxyz{|}~

NOTE: When you activate the BER Test, the 2036P “memorizes” the setting of

Switches S1, S3,S4, S5, S6, S7, and S8 to perform the test. If you modify any of

these switches, you must de-activate Switch 2 in order for the changes to take effect.

5

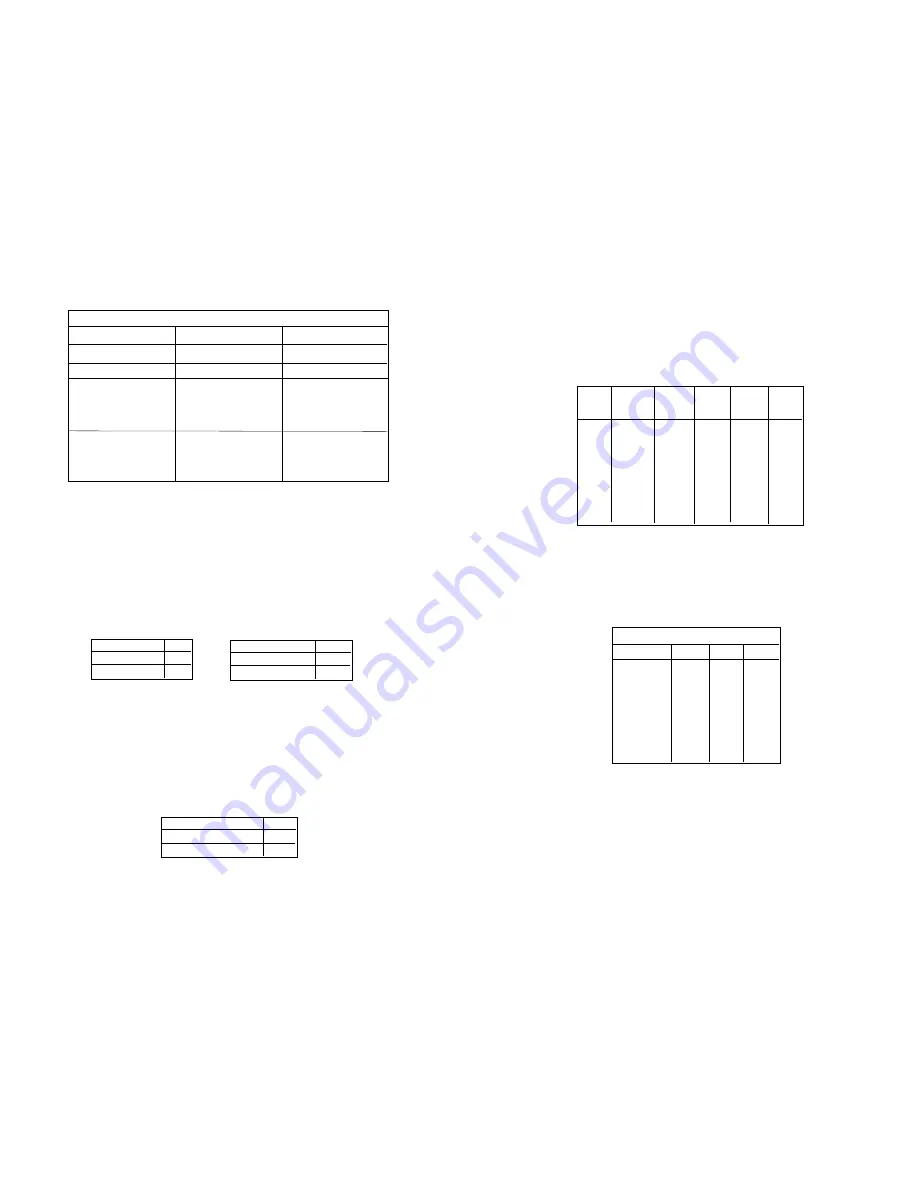

DIP SWITCH SUMMARY TABLE

Position

Function

Factory Default

SW1

Flow Control

Off

SW2

Bit Error Rate Test

Off

De-Activated

SW3

Data, Parity, Stop Bits

Off

SW4

Data, Parity, Stop Bits

Off

SW5

Data, Parity, Stop Bits

Off

SW6

Data Rate

Off

SW7

Data Rate

Off

SW8

Data Rate

Off

Hardware

8B, NP, 1S

38400 bps

}

}

Flow Control SW1

Hardware

OFF

Software

ON

BERT Direction SW1

Parallel

OFF

Serial

ON

Bit Error Rate

SW2

BERT Activated

ON

BERT De-activated

OFF

Switch 3 through 5: Data, Parity and Stop Bit

Switches 3 through 5 are used to specify the data, parity and stop

bits. The following table shows the settings that may be used:

Switches 6 through 8: Frequency and Data Rate

Switches 6 through 8 determine the frequency and data rate. The

following chart shows the settings that may be used:

6

1200

OFF

OFF

ON

2400

ON

OFF

ON

4800

ON ON

OFF

9600

OFF

ON

ON

19200

ON

ON

ON

38400

OFF

OFF

OFF

57600

ON

OFF

OFF

115200

OFF

ON

OFF

Serial Data Rate

Data Rate

SW6

SW7

SW8

7B

EP

1S

ON

ON

ON

7B

OP

1S

OFF

ON

ON

7B

NP

2S

ON

OFF

ON

7B

EP

2S

OFF

OFF

ON

7B

OP

2S

ON

ON

OFF

8B

EP

1S

OFF

ON

OFF

8B

OP

1S

ON

OFF

OFF

8B

NP

1S

OFF

OFF

OFF

Stop

Data

Parity

Bit

SW3

SW4

SW5