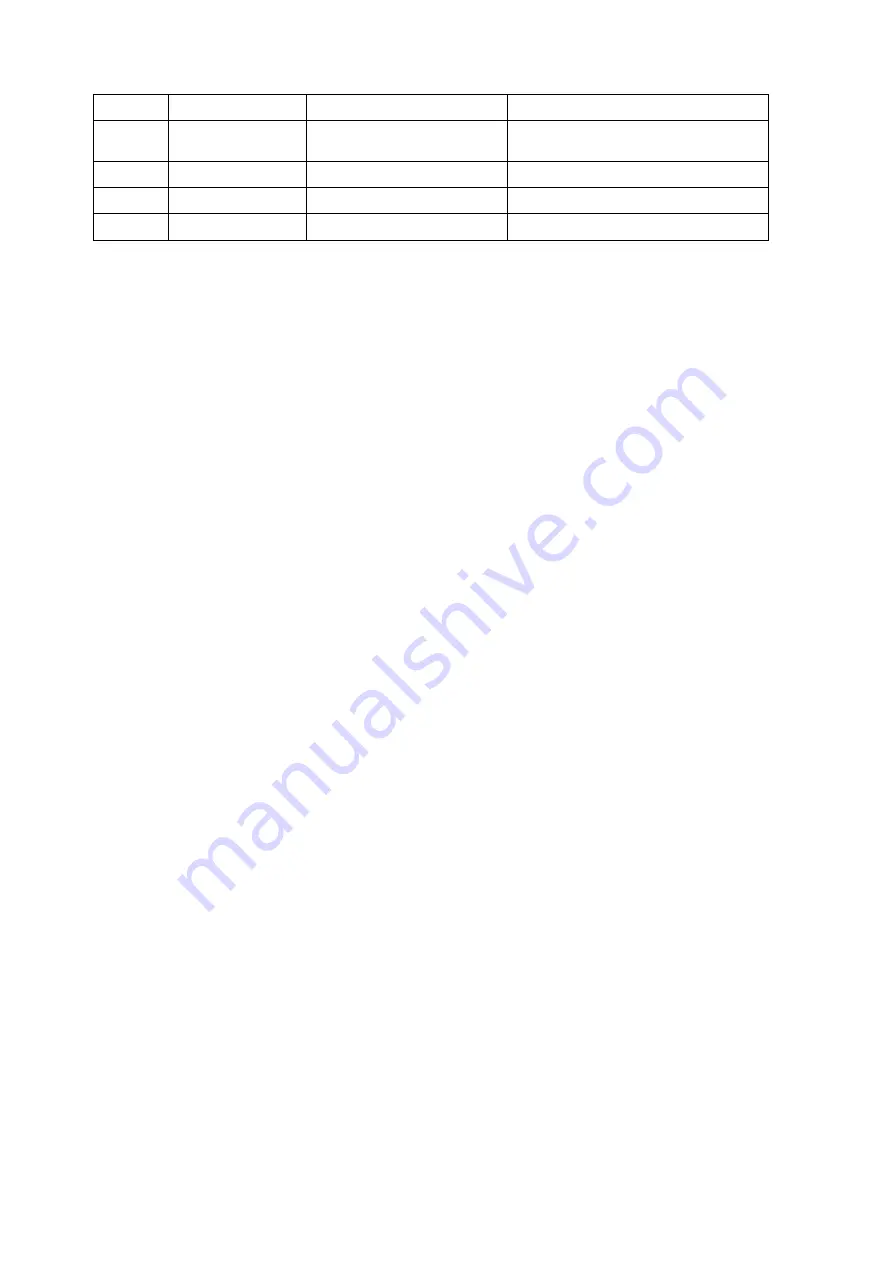

36

Position Pendular motion

Material

Comment

0

none

steel, aluminium, rubber,

ceramics

for fine/clean cuts in thin or hard

materials and rubber

1

small

plastics, wood, aluminium

hard materials

2

medium

wood

3

large

wood

soft materials, cut along the fiber

The best combination of stroke rate and pendular stroke setting is dependent upon the material being

worked on. The table is for reference only. It is recommended to perform a test run on a piece of scrap

material.

Sawdust blower

The sawdust blower leads an air jet to the saw blade. The air jet keeps sawdust from covering the cutting

line while working. The air flow can be switched on or off with the vacuum flow control (8).

•

Blower effect switched on (see Picture G) – For working with wood, plastic and similar materials that

produce large amounts of sawdust.

•

Blower effect switched off (see Picture H) – For working with metal and with use of coolant /

lubricant as well as when using dust / chip extraction.

Adjusting the cutting angle (see Picture F)

After loosening the screw (25), the bottom plate (7) can be moved forward and backward, and inclined

leftward and rightward into desired angle according to scale (27). The angle reading is indicated in the U-

shaped window of the pressing block (24) on the bottom plate. The bottom plate is set to 0°angle from

the factory.

•

Before adjusting the cutting angle, remove the protective cover (21).

•

Loosen the tightening screw (25) with the allen key (17) far enough so that the saw foot (7) can be

easily turned.

•

Set the saw foot to the desired position 15°/30°/45° on the angle scale (27) and retighten the screw.

Straight cut (see Picture E, right)

When using the jigsaw to perform straight cuts, remember to attach the cover (21), plastic guide (22)

and plastic sliding shoe (27) too. The plastic guide limits the material’s fringe when the guide is inserted

between the base plate (7) and the sliding shoe (27) at the location of blade opening. The guide sits in

the opening with its raised side facing downwards to the worked surface and with flat side facing

upwards to the saw foot. The notch in the guide is facing to the rear of the machine. Do not use the

guide (22) when making curved or angled cuts.

Angled cut (see Picture E, left)

For angled cuts, the protective cover (21) and guide (22) must be removed. Sliding shoe (27) can be used

if the worked surface is sensitive.

Plunge cut (see Picture D)

Only soft working materials, such as wood or plaster cardboard, may be used for dip sawing! For dip

sawing, only use suitable saw blades and always set the sawing angle to 0°.

•

Place the front of the saw foot (7) on the workpiece so that the blade tip does not touch surface.

•

Set maximum stroke rate, zero pendulum and switch the jig saw on.

•

Slowly reduce the angle of support of the saw foot in the direction of the workpiece. The saw blade

„dips“ into the material.

•

As soon as the saw foot lies smoothly on the workpiece, you can begin sawing.