www.parweld.com

6

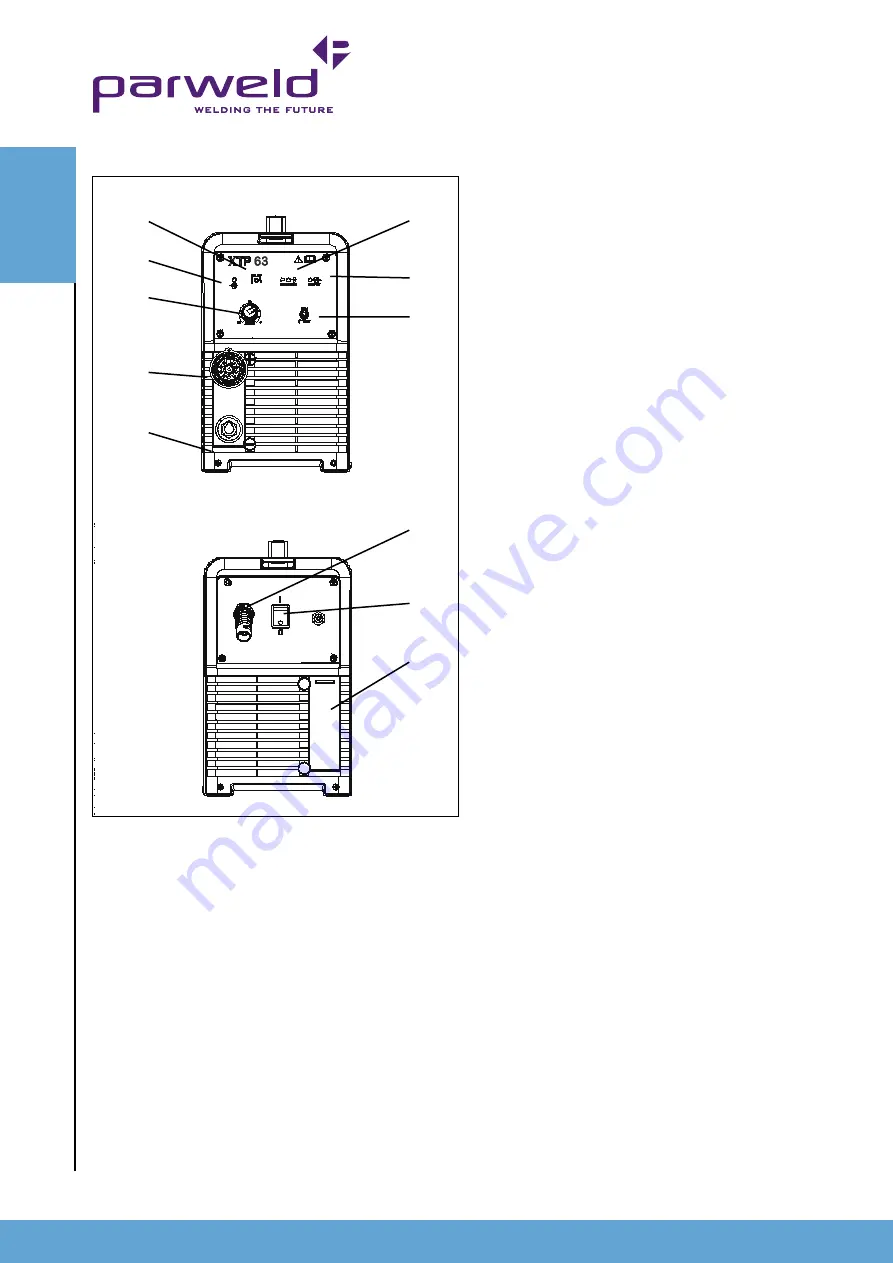

8) Torch connector

9) Earth lead connector.

10) Air line connector

11) Consumable holder

5.0 Installation

Read entire installation section before starting installation.

SaFetY preCautIOnS

• ELECTRIC SHOCK can kill.

• Only qualified personnel should perform this installation.

• Only personnel that have read and understood the Operating

Manual should install and operate this equipment.

• Machine must be grounded per any national, local or other

applicable electrical regulations.

• The power switch is to be in the OFF position when installing

work cable and torch and when connecting other equipment.

5.1 Unpacking the Machine

Carefully remove the machine from the packaging, we recommend

you retain the packaging until the machine has been fully installed

and tested incase it has been damaged in transit and has to be

returned to the re-seller.

5.2 location

Be sure to locate the welder according to the following guidelines:

In areas, free from moisture and dust.

Ambient temperature between 0-40

0

C.

In areas, free from oil, steam and corrosive gases.

In areas, not subjected to abnormal vibration or shock.

In areas not exposed to direct sunlight or rain.

Place at a distance of 12” (300 mm) or more from walls or similar

that could restrict natural airflow for cooling.

5.3 Input and grounding connection

WarnInG

Before starting the installation, check that your power supply

is adequate for the voltage, amperage, phase, and frequency

specified on the Machine nameplate.

Operate the welding power source from a single-phase 50/60 Hz,

AC power supply. The input voltage must match one of the electrical

input voltages shown on the input data label on the unit nameplate.

The XTP-63 machine can be used on 400V supply and will

automatically adjust itself depending upon the voltage applied.

Refer to the specifications table for voltage tolerances.

Have a qualified electrician connect the input plug. For long runs

over 30m , larger copper wires should be used. The green/yellow

wire in the input cable connects to the frame of the machine. This

ensures proper grounding of the machine when the machine plug is

inserted into the receptacle.

4.0 Description of Controls

1) ON OFF Switch for switching on or off the mains supply to the

machine. The switch is mounted on the rear panel.

2) Fault light This indicates a fault or over temperature condition

with the machine refer to the fault finding section for further

information

3) Power light This indicates mains power is applied to the machine

and that the machine is currently switched on when the light is

illuminated

4) Output power control for adjustment of the power output of the

machine between 20 and 60Amps.

5) Interlock fault. If this light illuminates it indicates one of the

following. Short circuit between the electrode and tip, front end torch

parts missing or incorrectly fitted, Shield cup not fitted correctly

(lamp flashes) low air pressure.

6) Output power on. Illuminates when the DC output current is on.

7) Run/Set switch. In the set position the Air can be checked by

pressing the trigger to ensure the air is connected and flowing.

CO

ntr

O

lS

1

10

11

5

6

7

2

3

4

8

9

Содержание XTP-63

Страница 1: ...Operator Manual ISSUE 1 XTP 63...

Страница 13: ...www parweld com 13...