www.parweld.co.uk

13

ACCESSORIES

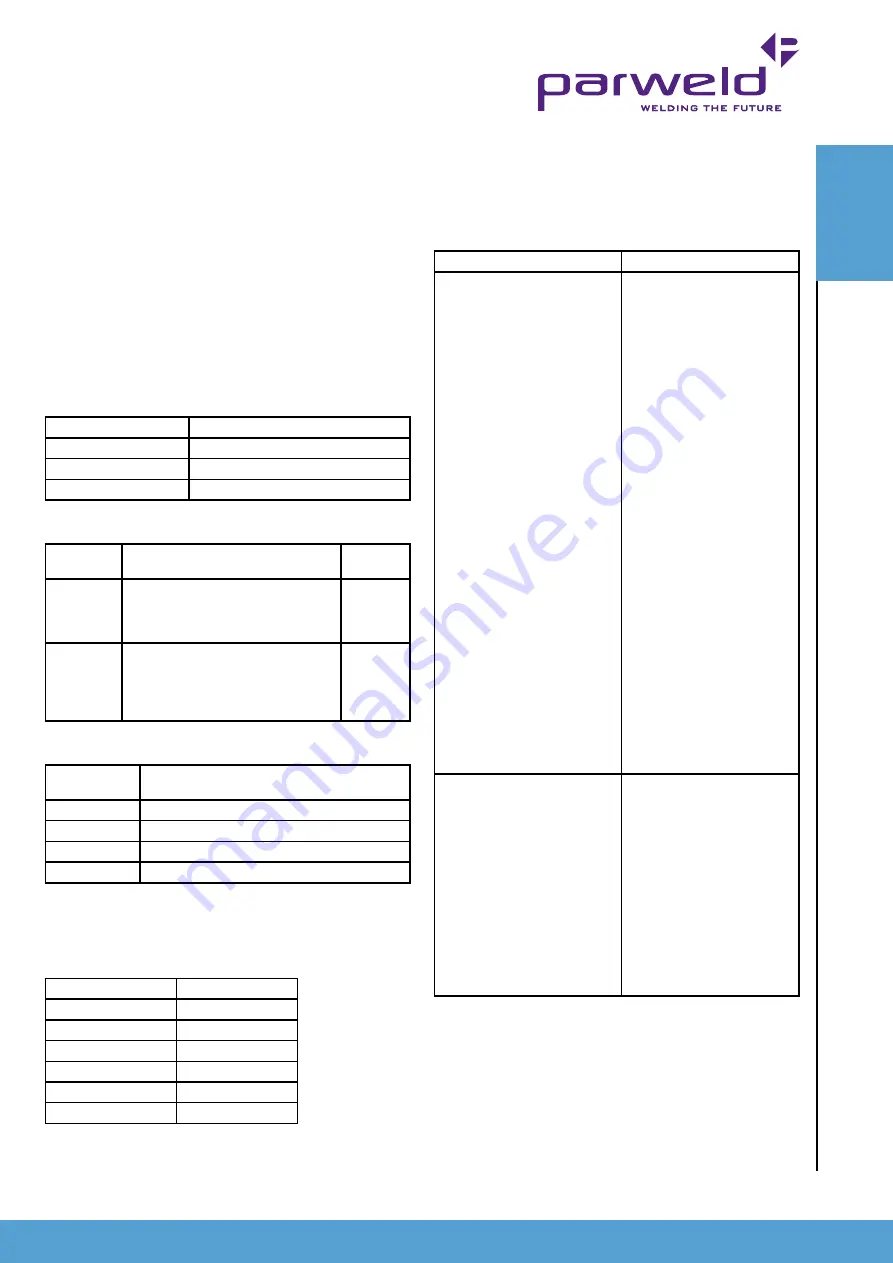

tIG WelDInG GuIDe ranGeS

Electrode diameter

DC current (amps)

0.040” (1.0mm)

30 – 60

1/16” (1.6mm)

60 – 115

3/32” (2.4mm)

100 – 165

tunGSten eleCtrODe tYpeS

Electrode

type

Welding application

Colour

code

Thoriated

2%

DC welding of mild steel, stainless

steel and copper. Excellent arc

starting, long life, high current carrying

capacity.

RED

Ceriated

2%

DC welding of mild steel, stainless

steel, copper, aluminium, their alloys

longer life, more stable arc, easier

starting, wider current range, narrower

more concentrated arc

GREY

GuIDe FOr SeleCtInG FIller WIre DIaMeter

Filler wire

diameter

DC current range

1/16” (1.6 mm)

20 - 90

3/32” (2.4 mm)

65 - 115

1/8” (3.2 mm)

100 - 165

3/16” (4.8 mm)

200-350

The filler wire diameter specified is a guide only, other diameter

wires may be used according to the welding application.

SHIelDInG GaS SeleCtIOn

Alloy

Shielding gas

Aluminium & alloys

Pure Argon

Carbon steel

Pure Argon

Stainless steel

Pure Argon

Nickel alloy

Pure Argon

Copper

Pure Argon

Titanium

Pure Argon

7.0

Fault finding

7.1 MIG WELDInG PROBLEMS

problem

Cause/Corrective action

Porosity - small cavities or holes

Resulting from gas

pockets in weld metal.

Inadequate shielding

gas coverage. Check for

proper gas flow rate.

Remove spatter

from gun nozzle.

Check gas hoses for leaks.

Eliminate drafts

near welding arc.

Place nozzle 6-13 mm from

work piece Hold gun near

bead at end of weld until

molten metal solidifies.

Wrong gas. Use welding

grade shielding gas; change

to different gas.

Dirty welding wire. Use

clean, dry welding wire.

Eliminate pickup of oil or

lubricant on welding wire from

feeder or liner.

Work piece dirty. Remove all

grease, oil, moisture, rust,

paint, coatings, and dirt from

work surface before welding.

Use a more highly deoxidizing

welding wire (contact supplier).

Welding wire extends too

far out of nozzle.

Be sure welding wire

extends not more than 13

mm beyond nozzle.

Incomplete fusion to base metal

Work piece dirty. Remove all

grease, oil, moisture, rust,

paint, coatings, and dirt from

work surface before welding.

Insufficient heat input. Select

higher voltage range and/or

adjust wire feed speed.

Improper welding technique.

Place stringer bead in

proper locations) at joint

during welding.

Adjust work angle or widen

groove to access bottom

during welding.

(as a guide only 1.0mm material thickness = 30amps of welding

Current)

7. You are now ready to begin, switch on the gas. Lightly touch the

Tungsten Electrode to the work piece and draw the torch away

extending the arc to around 3-5mm

Содержание XTM 405i

Страница 1: ...Operator Manual ISSUE 1 XTM 405i XTM 505i...

Страница 17: ...www parweld co uk 17 FAULT FINDING...