Address:

Tel:

Email:

Web:

Engineer Planned Preventative Maintenance Schedule

Your gate will need to receive regular planned preventative maintenance in order to remain in safe

and reliable service. The maintenance outlined below should only be conducted by a trained and

qualified powered gate specialist who is familiar with

9

7

00

automation equipment and has the

necessary test equipment.

[insert company]

can provide this service and you will have been offered

a maintenance contract as part of the supply process. If the maintenance outlined below is not

completed,

[insert company]

cannot accept responsibility for injuries, accidents or breakdowns

caused by lack of maintenance.

You are reminded that, as the person in control of the gate, you have a legal duty of care to users

and to visitors to the premises (including trespassers). If the gate is not kept safe, any party whose

property is damaged or who is injured by the gate is likely to be able to sue for damages.

If the gate is part of an undertaking (such as at rented property), the person in control of it will have

additional duties under section 3 of the Health and Safety at Work Act 1974 to keep the gate

maintained in a safe condition.

If the premises are also a workplace, there are specific duties under regulation 5 and 18 of the

Workplace (Health and Safety and Welfare) Regulations 1992.

Failure to meet duties imposed by health and safety legislation can result in criminal proceedings.

A maintenance log is provided at the end of this book to record completed maintenance. Please

make sure the maintenance log is completed and signed on completion of any maintenance work.

At

6 month

intervals:

Inspections:

Check and grease bearing at the top

Check that all gearbox and motor mountings are tight and secure

Check that the gate manual release is still functioning

Check that the gate moves stable and freely when the manual release is engaged and power is

switched off!

Check all running gear fixings are tight and secure

Check flashing beacon is working

Check that the emergency stop button works

Check all safety edges work and are working for the correct direction of travel

Check the photocells are working and in the correct direction of travel

Check that no one has made the gate unsafe by speeding it up past the factory settings

Check that the control program has not been modified such as to make the gate unsafe. Please

consult the manufacturer if in doubt

Call the manufacturer to talk this through if in doubt, use common sense and it is better to check

everything twice!

Содержание PF9700

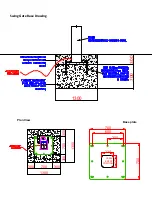

Страница 13: ...Address Tel Email Web Engineers Sec on Not For End Users Control Panel Overview...

Страница 20: ...Address Tel Email Web...

Страница 21: ...Address Tel Email Web...

Страница 22: ...Address Tel Email Web...

Страница 23: ...Address Tel Email Web...

Страница 24: ...Address Tel Email Web...

Страница 25: ...Address Tel Email Web...

Страница 26: ...Address Tel Email Web...

Страница 27: ...Address Tel Email Web 24v From External PSU Switch to Drop Bolt...