Address:

Tel:

Email:

Web:

Parameter Function

Parameter

Display Adj. Range

Factory

Setting

P.410

[Sec]

0.0 to 990.0

10

-2

n

5

P.415

[Sec]

0.0 to 990.0

10

-2

n

5

P.419

[Sec]

0.0 to 990.0

6

0

P.501

0401

P.502

0

101

P.503

0

701

P.504

1501

P.505

1502

P.506

0501

P.507

0501

P.508

0102

P.509

1111

P.50A

1612

Run time monitoring for deadman operation

Time set is the max run time for deadman operation, if movement takes longer then F.020 will display

Run time monitoring for the close direction

Time set is the max run time for the close direction, if movement takes longer then F.020 will display

Run time monitoring for the open direction

Time set is the max run time for the open direction, if movement takes longer then F.020 will display

Run Timer Parameters

Input Parameters

0000

to

1806

More options avaliable, check pages 103-108 of the Feig Parameter Description Total Overview manual

Input 1-9 profiles

0101: Open command (N/O) to fully open position with auto close (P.010)

0102: Open command to intermediate position with auto close (P.010) position adjustable with P.244

0205: Impulse command (N/O) to fully open position without auto close, close on next command

0501: Safety input (N/C) safety reversing when closing to open position

0401: Stop command (N/C) stop in any direction and wait for another command after release

0701: Close command (N/O)

1501: Simulate foil button open (N/O) (works the same way as the up arrow on the lid of the controller)

0000 1502: Simulate foil button close (N/O) (works the same way as the down arrow on the lid of the controller)

1612: Safety input (8k2) safety reversing when opening

P.461

[Cnt]

0 to 5

Safety Edge Parameters

Closing safety edge operation

0

Maximum number of reversals

Maximum amount of times the gate will reverse if the closing safety edge is hit before displaying F.361 (0 to disable)

0: Deactivated (make sure cables are removed from terminals)

1: 8k2 resistive safety edge normally open

2: 8k2 resistive safety edge normally closed

1

3: 8k2 resistive safety edge normally open with testing in closed position

4: 8k2 resistive safety edge normally closed with testing in closed position

5: Dynamic optical system

P.460

0 to 6

6: Automatic detection of the connected safety edge

Содержание PF9700

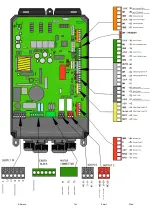

Страница 13: ...Address Tel Email Web Engineers Sec on Not For End Users Control Panel Overview...

Страница 20: ...Address Tel Email Web...

Страница 21: ...Address Tel Email Web...

Страница 22: ...Address Tel Email Web...

Страница 23: ...Address Tel Email Web...

Страница 24: ...Address Tel Email Web...

Страница 25: ...Address Tel Email Web...

Страница 26: ...Address Tel Email Web...

Страница 27: ...Address Tel Email Web 24v From External PSU Switch to Drop Bolt...