33

WWW.PARKERMOTION.COM

PH: (724)

-

861

-

8200

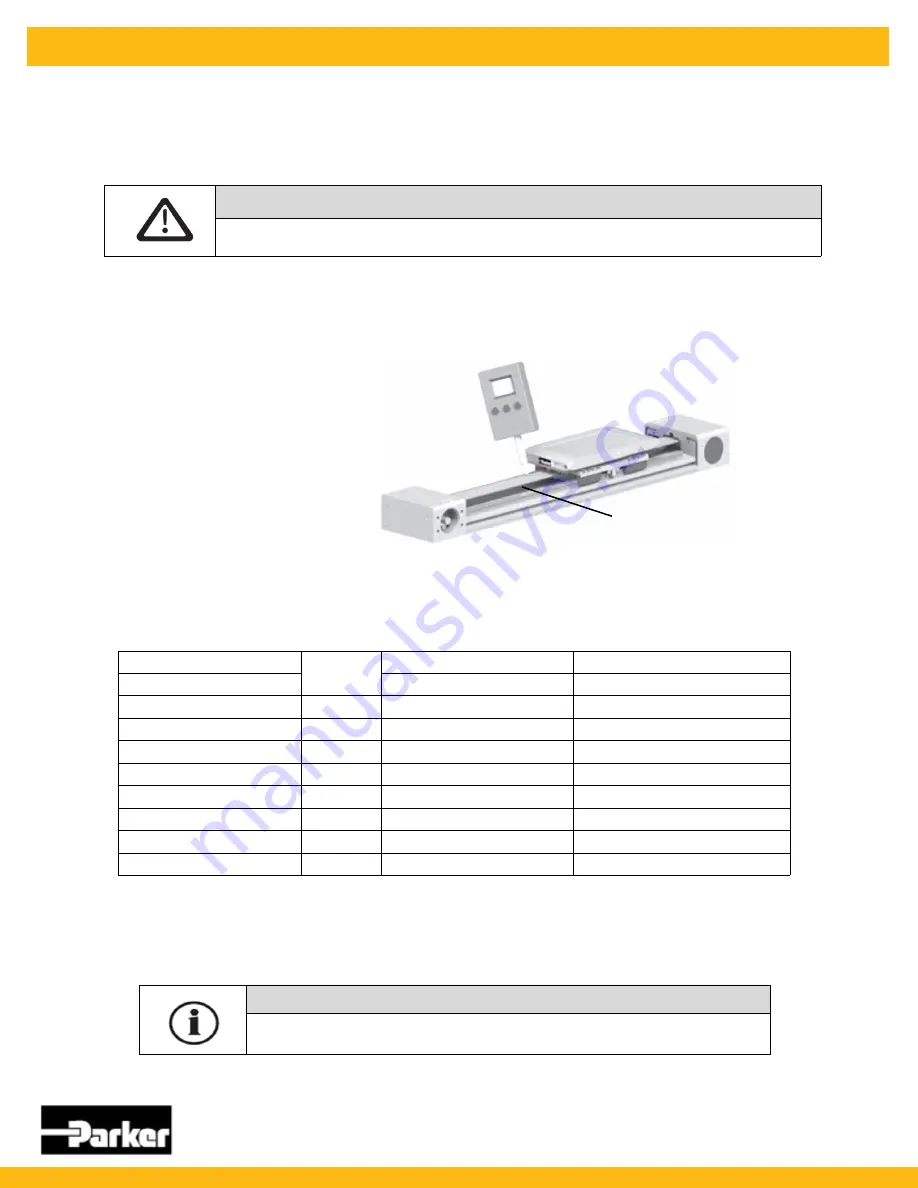

HMR Series Positioners

9.7.1

Check belt tensioning

The most certain results measuring belt tensioning can be adjusted and reviewed in practice by an experienced specialist.

However, the toothed belt tension is measured and adjusted most reliably by using a belt tension measuring device. One

method is to adjust using the

frequency meter

.

Please direct any queries related to purchasing or loan of a rate monitor to the manufacturer directly.

•

If present the IP54 cover must be removed described in section. 7.4.1.

•

The payload must be removed from vertical oriented positioners.

•

Move the carriage unloaded in both directions so the belt will subside.

•

Adjust

distance A

from the center of the

drive shaft

to the

carriage

with 500 mm or 250 mm

on short positioners.

•

Activate the

toothed belt

by pulling the center of the clear toothed belt until it vibrates.

•

Measure the resulting frequency in the center of the clear toothed belt length with the

frequency meter

.

Take the measurement three times.

•

Check the measured frequency with values from following table.

•

Follow the instructions depending of the measured variance:

f < 70%

Replacement of the belt.

70% < f < 90%

Retension the belt.

90% < f < 110%

No action necessary.

Attention

The max. permissible pulling force of the toothed belt may not be exceeded under any circumstances.

Frequency meter

Belt

Product size,

Belt

Clear belt length 500mm

Clear belt length 250mm

Motor mounting position

Frequency

Frequency

HMR08

20 AT 3

85 Hz

170 Hz

HMR11

25 RPP 5

83 Hz

166 Hz

HMR15/090°/270°

40 RPP 5

85 Hz

170 Hz

HMR15/0°/180°

25 RPP 5

83 Hz

166 Hz

HMR18/090°/270°

50 RPP 5

86 Hz

172 Hz

HMR18/0°/180°

40 RPP 5

83 Hz

166 Hz

HMR24/90°/270°

75 RPP 8

88 Hz

176 Hz

HMR24/0°/180°

50 RPP 8

108 Hz

216 Hz

NOTE

After retensioning the belt twice a replacement is necessary