Refrigerating Specialties Division

8

Maintenance and Service (continued)

Electrical

The Refrigerating Specialties Division molded water resistant Class

“B” solenoid coil is designed for long life and powerful opening force.

The standard coil housing meets NEMA 3R and 4 requirements. This

sealed construction can withstand direct contact with moisture and

ice. The coil housing far exceeds the requirements of NEMA Standard

ICS, 1-110.57 salt spray test for rust resistance.

By definition, Class “B” coil construction will permit coil temperatures,

as measured by resistance method, as high as 130°C (266°F). Final

coil temperatures are a function of both fluid and ambient temperatures.

The higher fluid temperatures require lower ambient temperatures so

the maximum coil temperature is not exceeded. Conversely, low fluid

temperatures permit higher ambient temperatures.

The molded Class “B” coil is available from stock with most standard

voltages. However, coils are available for other voltages and

frequencies, as well as for direct current. Coils are also available as

transformer type with a 6 volt secondary winding for use with the

Refrigerating Specialties Division Pilot Light Assembly (see current

copy of Bulletin 60-10, “Pilot Light Assembly and Solenoid Transformer

Coil”).

The solenoid coil must be connected to electrical lines with volts and

Hertz same as stamped on coil. The supply circuits must be properly

sized to give adequate voltage at the coil leads even when other

electrical equipment is operating. The coil is designed to operate with

line voltage from 85% to 110% of rated coil voltage. Operating with a

line voltage above or below these limits may result in coil burnout.

Also, operating with line voltage below the limit will definitely result in

lowering the valve opening pressure differential. Power consumption

during normal operation will be 33 watts or less.

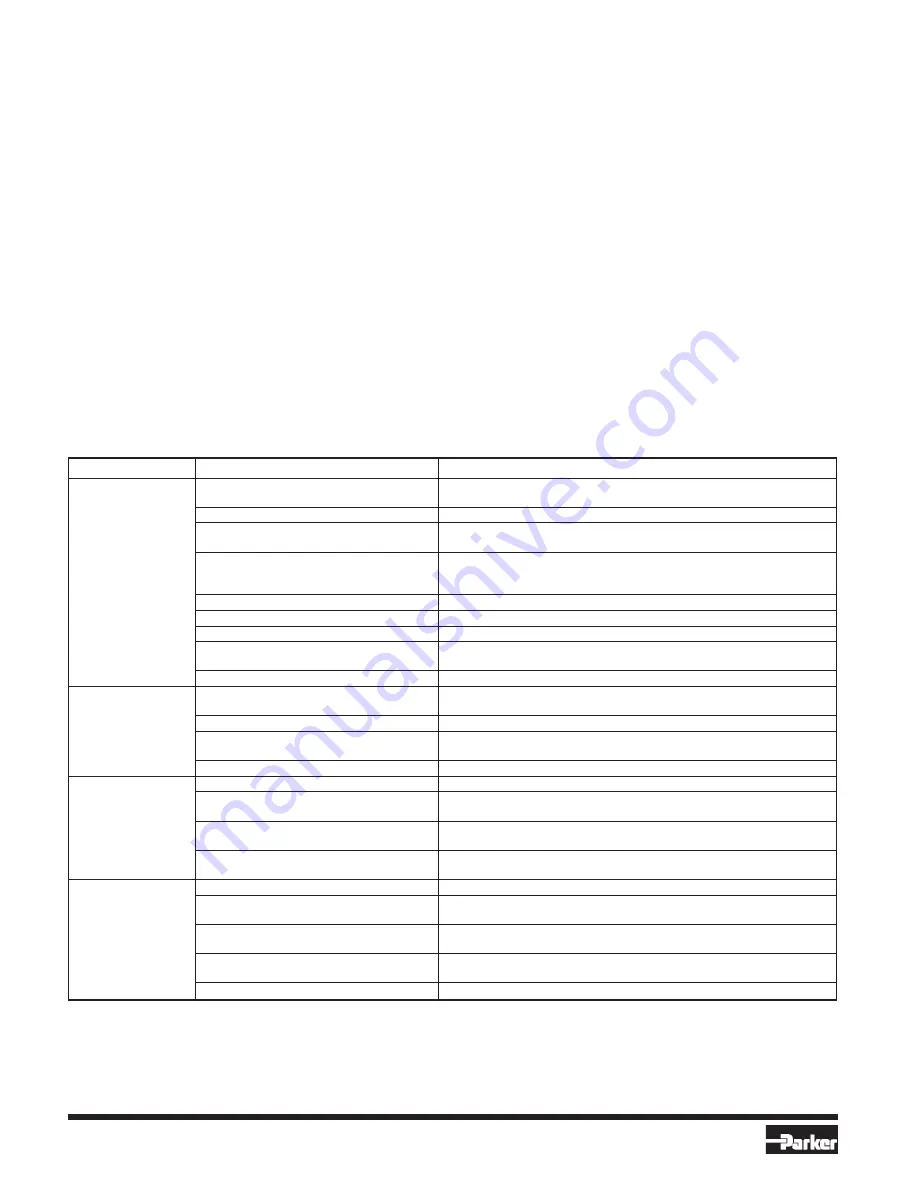

Inrush and running current is listed below:

Inrush Running Fuse

Standard Coil

Current Current Size

Vohs/Hertz

(Amps) (Amps) (Amps)

120/60 (Blue leads)

1.1860

0.46

1

208/60 (Blue & Red leads)

0.63

0.26

1

240/60 (Red leads)

0.60

0.23

1

440/60 (Yellow & Red leads)

0.39

0.13

1

115/50 (Yellow & Blue leads)

1.22

0.21

1

230/50 (Yellow leads)

0.65

0.26

1

Other

Contact Factory

On transformer coil the 6 volt leads are always black.

SYMPTOM

PROBABLE REASON

CORRECTION

Regulator does not

Diaphragm or seat dirty, damaged or frozen.

Clean or replace. Clean strainer.

shut off flow.

Diaphragm follower stuck or damged.

Clean or replace. Install follower carefully.

Piston jammed with excess dirt.

Remove and polish piston and bore with crocus cloth. Clean valve and

strainer.

Throttling plug leaking due to excess

Clean or replace. If used on liquid, check for

dirt or damage.

erosion due to excessive flash gas. Reduce flash gas by subcooling or by

reducing pressure drop across valve by providing restriction at valve outlet.

Diaphragm ruptured or badly deformed.

Replace. If Range “D” make sure has 2 diaphragms.

A4AB Modular Solenoid Pilot seat leaking.

Check seat and needle. Replace as needed,

A4AS Modular Solenoid Pilot seat leaking.

Check seat and needle. Replace as needed.

Diaphragm and seat eroded due to flash gas.

Replace. Reduce flash gas by subcooling or by reducing pressure drop

across regulator by providing restriction at valve outlet.

Modular Solenoid Pilot not closing.

Check power at leads, make sure coil is de-energized.

Regulator does not

A4A (inlet) Pressure Regulator Diaphragm

Replace. It Range D make sure has 2

open

ruptured or badly deformed.

diaphragms.

Diaphragm follower stuck, damaged or frozen.

Clean or replace. Install follower carefully.

A4AS/A4AB Modular Solenoid

Pressure drop across valve too high; over 21 bar (300 psig). Lower pressure

Pilot not opening.

drop. Improper power supply. Correct. Replace solenoid coil.

Piston worn, too much clearance.

Replace piston. Check for reason. If used on liquid, check for flash gas.

Regulator Operation

Diaphragm or seat dirty or damaged.

Clean or replace. Clean strainer.

erratic.

Diaphragm follower has dirt on the outside

Clean or replace.

diameter or outside diameter is damaged.

Other system components, line controllers,

Adjust, repair or replace.

thermostats, etc., erratic.

Regulator too far oversized.

Check load. Replace with smaller regulator or investigate use of reduced

capacity plug.

Pressure drop across

Inlet or outlet restricted.

Check for restriction. Clean strainer.

regulator too high.

Regulator too small.

Open manually to be sure valve is full open.

Replace with proper size regulator.

Large amount of flash gas in liquid line.

Reduce flash gas by subcooling. Reduce line restriction by increasing line

size, particularly at the regulator outlet. Replace with larger regulator.

High pressure drop causes high rate of

Increase pipe size at the outlet of the

expansion of gas at regulator outlet.

regulator.

Regulator does not open all the way.

Check piston for wear. Replace, it needed.

SERVICE POINTERS (Check General Procedure)