10

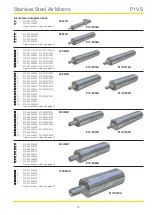

Stainless Steel Air Motors

P1V-S

The noise from an air motor consists of both mechanical noise and a

pulsating noise from the air flowing out of the outlet. The installation

of the motor has a considerable effect on mechanical noise. It should

be installed so that no mechanical resonance effects occur. The

outlet air creates a noise level which can amount to 108 dB(A) if the

air is allowed to exhaust freely into the atmosphere. To reduce noise

levels, various types of outlet silencer are used. The most common

type screws directly into the outlet port of the motor. A wide range of

silencers are available. Many are made of sintered brass or sintered

plastic. Since the motor function causes the exhaust air to pulsate, it

is a good idea to allow the air to exhaust into some kind of chamber

first, which reduces the pulsations before they reach the silencer. The

best silencing method is to connect a soft hose to a central silencer

allowing the speed of the air to reduce as much as possible.

NOTE!

Remember that if a silencer is too small or is blocked, back

pressure is generated on the outlet side of the motor, which in turn

reduces the motor power.

Sound levels

Sound levels are measured at free speed with the measuring

instrument positioned 1 m away from the air motor, see the table below

Air

Free outlet With outlet

Exhaust air removed

motor

silencer

with pipes to

another room

dB (A)

dB (A)

dB (A)

P1V-S00

98

-

74

P1V-S008

95

-

71

P1V-S01

99

9

70

P1V-S00

100

88

71

P1V-S030

103

91

70

P1V-S060

103

94

76

P1V-S10

108

95

87

Drilling,

With integrated

Exhaust air removed

milling

outlet silencer

with pipes to

and grinding

another room

motor

dB (A)

dB (A)

P1V-S008

85

71

P1V-S009

7

-

P1V-S017

74

70

P1V-S05

76

71

P1V-S040

77

70

Outlet silencer

Compressed air quality

Oil and oil mist are avoided whenever possible to ensure a

clean work environment. In addition, purchasing, installation

and maintenance of oil mist equipment can be expensive. All

users in all industries now try to avoid using components which

have to be lubricated.

The P1V-S motor is equipped with vanes for intermittent

lubrication free operation as standard, which is the most

common application of air motors. The motor is also available

with optional hard vanes for continuous lubrication-free opera-

tion (option “C”).

The P1V-S motor is equipped as standard with food grade

grease in the planetary gearbox. An oil which is approved by

the food industry is also available if supplementary lubrication

is required.

Working pressure

Max 7 bar (max 6 bar

in explosive atmospheres )

Working temperature

-30 °C to +100 °C

Ambient temperature

-0 °C to +40 °C

in explosive atmospheres

Medium

40 µm filtered, oil mist or

dry unlubricated compressed air

Dry unlubricated compressed air

If unlubricated compressed air is used, the compressed air should

comply with the purity standards below in order to guarantee the

longest possible overall service life. If the unlubricated compressed

air has a high water content, condensation forms inside the motor,

causing corrosion in all internal components. A ballbearing can be

destroyed in a remarkably short time if it comes into contact with a

single water droplet.

For indoor use, we recommend ISO8573-1 purity class 3.4.1. To

achieve this, compressors must be fitted with aftercoolers, oil filters,

refrigerant air dryers and air filters.

For indoor/outdoor use, we recommend ISO8573-1 purity class

1..1. To achieve this, compressors must be fitted with aftercoolers, oil

filters, adsorption dryers and dust filters.

Oil mist

If oil mist is used (approx. 1 drop of oil per m³ of compressed air), the

oil not only acts as a lubricant but also protects against corrosion. This

means that compressed air with a certain water content may be used

without causing corrosion problems inside the motor.

ISO8573-1 purity class 3.-.5 may be used without difficulty.

The following oils are recommended for use in the foodstuffs industry:

Shell Cassida Fluid HF 3 or Klüberoil 4 UH 1-3

ISO 8573-1 purity classes

Quality

Contaminants

Water

Oil

class

particle

max. con-

max. pressure max. con-

size

centration

dew point

centration

(µm)

(mg/m³)

(°C)

(mg/m³)

1

0,1

0,1

-70

0,01

2

1

1

-40

0,1

3

5

5

-0

1,0

4

15

8

+3

5,0

5

40

10

+7

5

6

-

-

+10

-

For example: compressed air to purity class 3.4.3

This means a 5 µm filter (standard filter), dew point +3 ºC (refrigerant

cooled) and an oil concentration of 1,0 mg oil/m³ (as supplied by a

standard compressor with a standard filter).

Silencing

Central silencer

Содержание 1P1V-S020A00005

Страница 66: ...66 Stainless Steel Air Motors P1V S...

Страница 67: ......