22

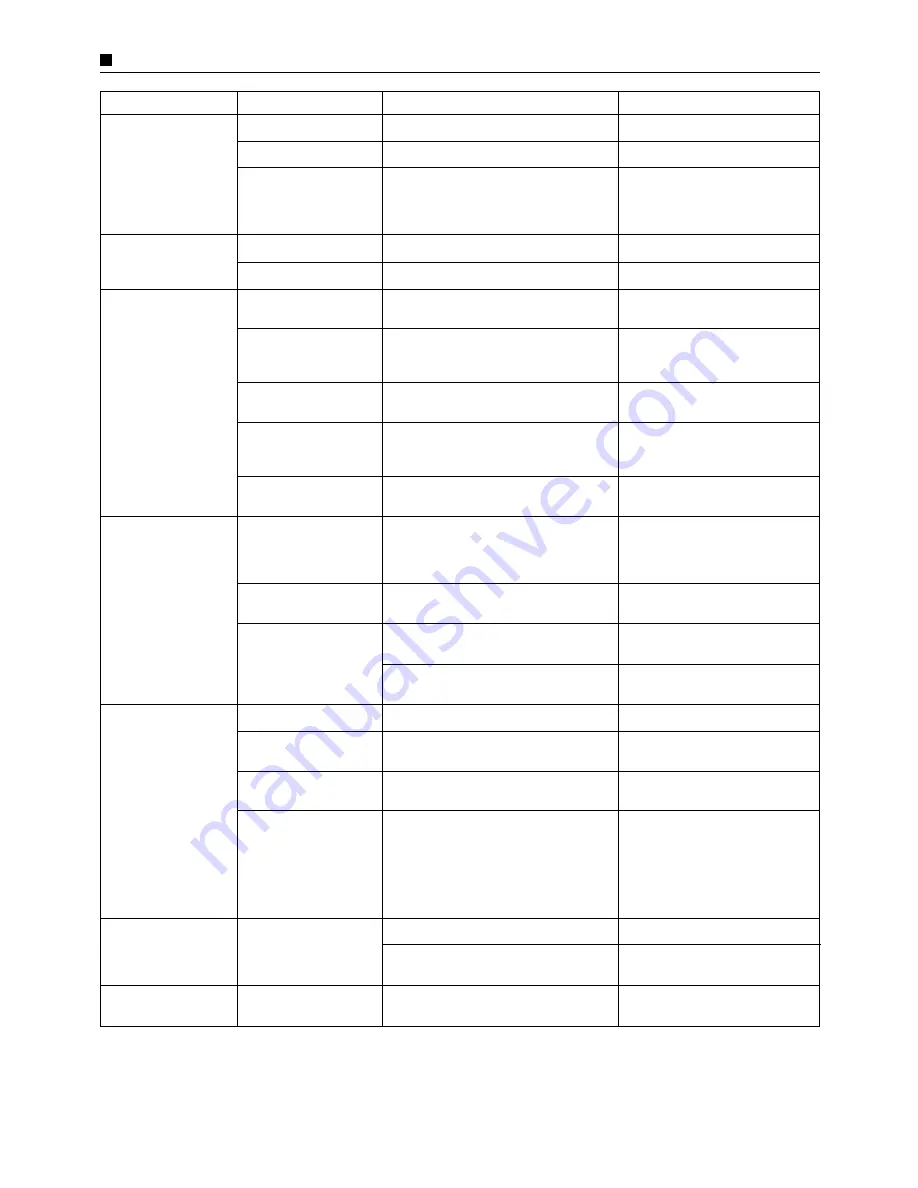

CONDITION

CHECKPOINT

METHOD OF INSPECTION

CAUSE / REMEDY

TROUBLE SHOOTING GUIDE

Vacuum cleaner

doesn’t work

Motor abnormal

Motor runs but does

not suction

Noise or vibration

Beater bar does not

rotate

Beater bar does

not stop in upright

position

(*)Dust sensor does

not work properly

Power supply cord

Fuse (Plug for UK only)

Thermal cut-out

Power control

Potentiometer circuit

Hose or suction pipe.

Dust bag / Central filter

Motor continuity

(Mains motor)

Carbon brushes

(Mains motor)

Triac

(Power control circuit)

Dust in motor fan

(Mains motor)

Carbon brushes

(Mains motor)

Beater bar

Beater bar motor

Beater bar ON/OFF

Switch

Beater bar Overcurrent

circuit breaker

Beater bar thermal

cut-out

Safety switch

Dust sensor circuit

Check power supply cord continuity.

Check fuse continuity.

Check thermal cut-out continuity.

Note: Continuity should be checked after

1 hours of removed plug from the mains

socket.

See diagram chart for (Motor abnormal pag. 23)

See diagram chart for (Motor abnormal pag. 23)

Check if there is any blockage in the

hose or suction pipe

Check if dust bag is full or dust

accumulated in central filter.

Check motor continuity across carbon

brush holder tabs.

Check gap between carbon brush and

commutator.

Check triac continuity between (TP5- TP7).

Check dust accumulated in motor fan.

(It could happen if the vacuum cleaner

has been used with a broken bag or

without central filter.

Check uneven wear of carbon brushes.

Check if beater bar unit is correctly

positioned in their holding points.

Check if beater bar holding points are

deformed or broken.

See diagram chart for (Motor abnormal) pag. 23)

Check continuity across ON/OFF

Switch tabs.

Check continuity across circuit

breaker tabs.

Remove thermal cut-out connector and

check continuity between connector

terminals CN22 .

(See schematic diagram)

Note: Continuity should be checked after

1 hour of removed plug from the mains

socket.

Check continuity across safety switch tabs.

Check that safety switch actuator is correctly

assembled.

See diagram chart for (Dust sensor

abnormal pag. 23).

If there is no continuity, replace it.

If there is no continuity, replace it.

If ther is no continuity, replace it.

As indicated on the diagram chart.

As indicated on the diagram chart.

If there is any blockage, remove it.

If paper bag is choked up, replace it.

If central filter is completely dirt, clean

or replace it.

If there is no continuity, replace the

motor.

If there is gap between carbon brush

and commutator, replace both

carbon brushes.

If there is no continuity, replace power

control circuit.

If there is dust accumulated in the

motor fan, replace the motor and

check filter condition. (Never try to

dismantle the motor fan).

If there is uneven wear, replace both

carbon brushes.

If it is not correctly positioned,

reassemble it.

If there are deformed or broken,

replace the cover ass’y.

As indicated on the diagram chart.

If there is no continuity, replace it.

If there is no continuity, replace it.

If there is no continuity, replace it.

If there is no continuity, replace it.

Reassemble it or replace.

As indicated on the diagram chart.

Note: (*) For models MC-E583K, MC-E583 only.

Содержание MC-E581

Страница 15: ...PACKING INSTRUCTIONS 1 2 3 4 ...