ー 26 ー

ー 27 ー

■

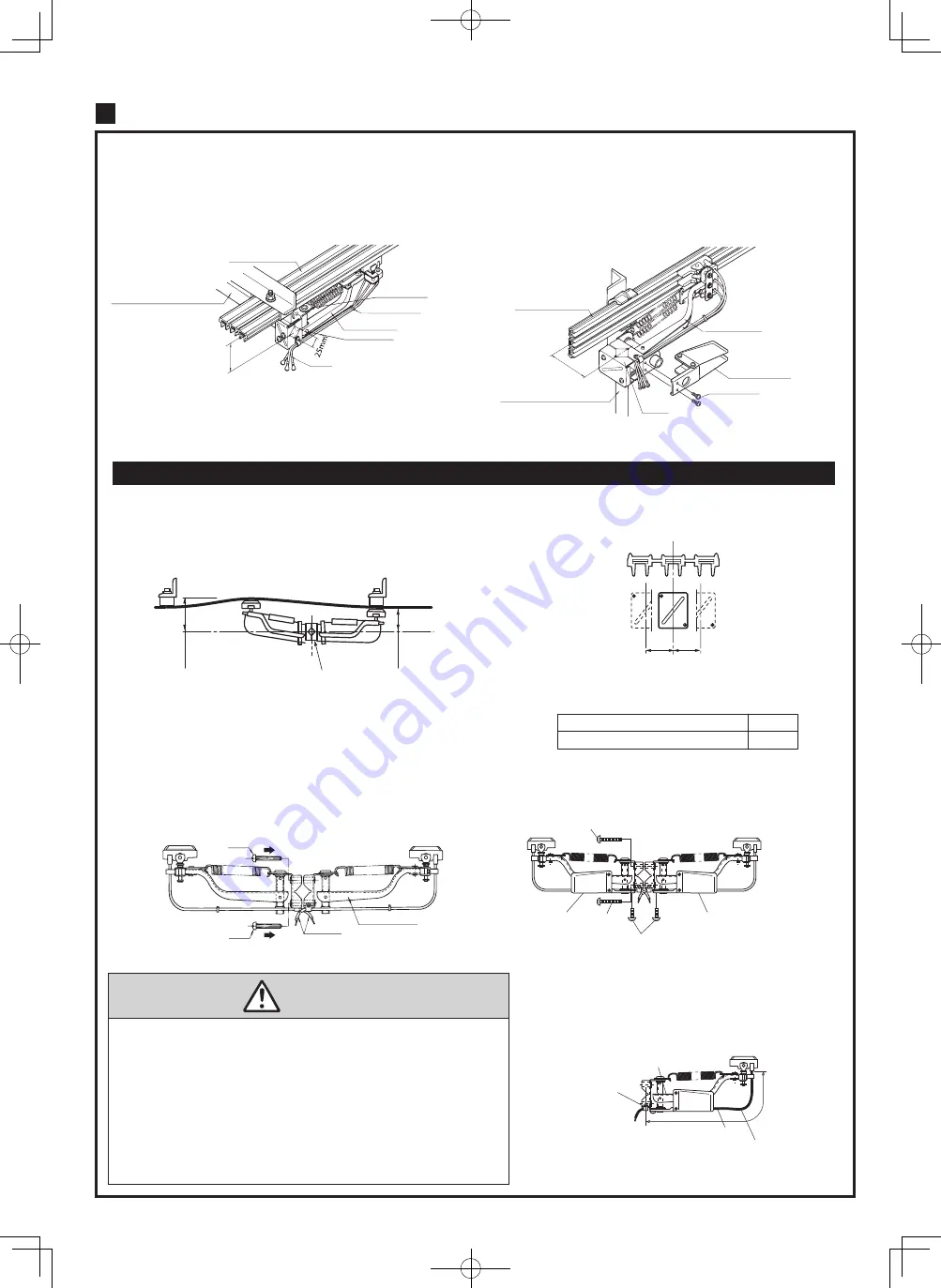

Standard installation

Set the distance between the High-Tro-Reel conductor sliding

surface and collector arm mount rod to 90mm (Central value of the

collector arm permitted movable range 90±20mm).

(Set the distance to 90mm at the hanger bracket section.)

(shown<A>)

When collector arm mount rod set up a referenceposition, the operating

range from 70mm

〜

110mm of collector arm set up to be twisting.

Adjust the arm mount rod between the High-Tro-Reel unit to become 110mm

or less and 70mm or more at the center between hangers, and 70mm or more

at the bracket.

■

Horizontal installation with its opening facing

As shown in a figure,mounted collector arm support parts for transverse on base of

the collector arm.Tightening torque of fixing screws

:

0.98 N

・

m

〜

1.32 N

・

m

Set the distance between the High-Tro-Reel conductor sliding surface

and collector arm mount rod to 90mm (Central value of the collector arm

permitted movable range 90±20mm).(shown<B>)

High-Tro-Reel unit

Lead

Lead

Lead

Collector arm

Collector arm

Collector arm

Fastening band

Bolt

Bolt

Bolt

Bolt

Use range of movable

<A>

<C>

Spring pin

Metal fittings

for spring

・

During operation of equipment, use the collector arm within permitted

movable range 90±20mm.

・

Be sure that collector arms are permitted movable range to the

High-Tro-Reel unit with no twisting.

・

Be sure to confirm the High-Tro-Reel unit phase (R.S.T) before

connecting the leads to the load.

・

In case of horizontal installation, be sure to use the Collector arm support

parts(for transverse) with its opening facing side.

Otherwise, poor collector arm contact or separation from wires may occur.

・

Mount the length from the center of the duct to the center of the collector

arm within A size.

■

Assembly in tandem configuration

Two collector arms (tandem type) should be used together in lines with

a circuit of 100A or higher, and especially in applications in which it is

imperative that collector arms not be separated from wires. (shown<C>)

Mounting the horizontal support parts in both the collector arms

Caution

Distance to the center of the collector arm

from the center of the duct

10

Collector arm installation

Collector arm mount rod,

25mm×25mm(not included)

(Permitted movable range)

90±20mm

Please refer even to page 21 for the CE type.

110mm

Collector arm mount rod

70mm

Base

Fixing screw

(

M4×8

)

Fixing screw

<B>

Collector arm

support parts

for transverse

Collector arm

support parts

for transverse

Collector arm

support parts

for transverse

High-Tro-Reel unit

Collector arm

Collector arm mount rod,

25mm×25mm(not included)

90±20mm

■

Wire clamp

■

Horizontal installation with its opening

facing into tandem-type

Give slack to a lead.(Lead is a fixed position,

380mm from the base of collector)

Do not affect a collector's run.

Dimension A of permitted movable range

Distance to the center of the collector arm

from the center of the duct

Use the horizontal support parts

5mm

Not use the horizontal support parts 15mm

A

A

Give slack to a lead.

380mm

Cable clamp

Screw

(

M6×12

)

Joiner

High-Tro Reel unit

Joiner cover

Joiner cover

Terminal Screw

(

M6×12

)

Crimp-on terminal

(

38m

㎡)

Terminal plate

Conductor

Hex key wrench (M6) <not included>

(Tightening torque: 9.3N • m ~ 11.3N • m)

Power wire <not included>

●

60A and 90A

(with feed-in terminal)

Knockout

Base

Rib for slide

Cover

Cover

Rib

Ribs cover-connection

(wires for: 38mm

2

)

Cover

Slide

Line in Side

Fastening band(not included)

Cable fixation part

Use fasten band

(width: 8mm following thickness: 1.7mm )

Slit

Cover

screwdriver <not included>

Ribs cover-

connection

Higt-Tro-Reel unit

Sliding the cover to overcome the rib to ensure.

2.Fixing power wires

1.Connect the power wire

3.Close cover

■

Removing the cover

Insert the screwdriver

<not included>into the

slit of the cover,Slide the

cover in the lifting the cover.

Center feed-in joiner

1. Put up the power wires from the line entrance,connect the power wire to

the terminal plate using a crimp-on terminal(not included ).

Be sure to tighten the terminal screw by hex key wrench(M8:not included ).

(Tightening torque: 12.5N • m ~ 15N • m)

・

Please use the crimp terminal in accordance with JIS standard.

・

S terminals connected to the terminal, then connect the L terminal

・

Ending up on the wire as the wire is floating.

2. Band the power wire with the cable fixation part by fastening band

(not included ).

3. After connection with the feeder, insert the cover along the slide rib of

the Joiner base

Ribs inside the cover (both sides) are reliably caught and

is based slide rib Making sure that, slide the cover. The cover covers the

ends of the base rib-connection

L terminal

Power wire(width: CVT100mm

2

less) (not included)

Crimp Terminal (not included)

S terminal

Terminal screw

・

The terminal screws must be securely

tightened.(Tightening torque: 12.5N • m

~ 15N • m)

Failure to do so may cause fire or damage

due to falling of equipment.

・

Sliding the cover to overcome the

rib-Connection May cause electric shock.

Failure to do so may cause an electric

shock.

・

Fasten certainly a power line using the

fastening band.

Failure to do so may cause fire or damage

due to falling of equipment.

Caution

・

The terminal screw must be securely tightened.

(Tightening torque: 9.3N • m ~ 11.3N • m)

Failure to do so may cause fire or damage due to falling of equipment.

・

The cover to ensure.

Failure to do so may cause an electric shock.

Feeder connection

Joiner (with feed-in terminal)

1. Put up the power wires, connect the power wire to the terminal plate

using a crimp-on terminal.

Be sure to tighten the terminal screw by hex key wrench.

(Tightening torque: 9.3N • m ~ 11.3N • m)

2. After connection with the power wire , removes knockouts of the Joiner cover,

and cover. Cutting plane of the knockout must do the chipping with

the knife etc.

Caution