Operation manual for Narrow-pitch connectors F4S

Panasonic Corporation

industrial.panasonic.com/ac/e/

©

Panasonic Corporation 2017

ACCTF5E-5 201704

- 6 -

02-2. Precautions for board design

1) Circuit design

(1)When designing the terminal foot pattern, check the latest specifications and

examine the recommended foot pattern and dimensions of the metal mask opening.

The current recommendations are indicated on pages

13 and 14

.

(2)This connector is provided with soldering metals for preventing solder from

peeling off the terminal.

Make sure to design a foot pattern for the holding metal.

(3)

Foot pattern layout considering mountability

Since the header post is configured to extend to the bottom face of the molded

part, the following defects may occur if a pattern extends to the same area.

- When a large volume of solder is built up in the terminal back-fillet, solder is

likely to creep onto the molded part, causing solder bridges.

(Reason: Since slim designs are preferred, it is difficult to secure sufficient space

for pooling solder in the back-fillet.)

- Reworking becomes problematic if solder bridges occur.

Therefore, to prevent further solder creep, the terminal pattern is designed only up

to the molded part in MEW’s recommended PC-board pattern upon confirmation

of the soldering strength.

Holding metal

Socket

Header

Holding metal

This space is small, and thus when a

large volume of solder builds up

here, solder creeps onto the molded

part and causes solder bridges.

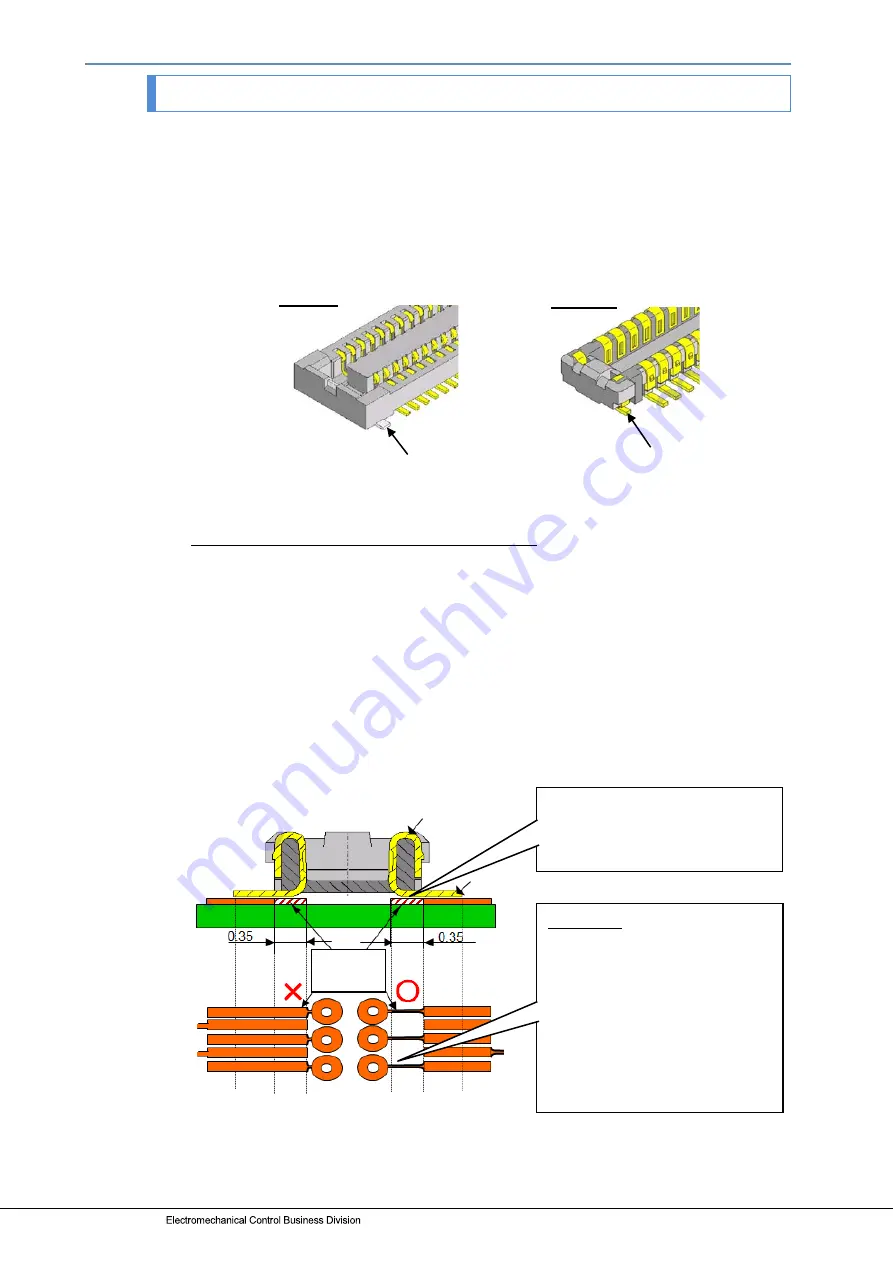

●

Key point

When a through-hole is made

under the connector, we

recommend that you thin the

pattern inside the prohibited area

as shown in the left-hand drawing

and provide a through-hole

outside the prohibited area.

In general, the pattern width in

this area is 1/3 the terminal

pattern width.

Sectional view

Top view

Through-hole

prohibited

area

post

terminal