Operation manual for Narrow-pitch connectors F4S

Panasonic Corporation

industrial.panasonic.com/ac/e/

©

Panasonic Corporation 2017

ACCTF5E-5 201704

- 9 -

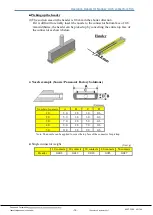

2) FPC board design

(1)

Positions of connectors on the FPC

The FPC board is made by laminating a polyimide layer, copper foil, and adhesive

layers. Since each material has slightly different heat-shrinkable properties,

warpage may occur typically due the reflow heat in the following cases. This may

cause poor soldering. Make sure to arrange the board in a direction that minimizes

warpage.

■

Example of the Assist carrier (ShinEtsu Polymer)

In case of a one-sided FPC board, warpage is

more likely to occur if a pattern is laid in a line,

or if the copper foil is applied over the entire

FPC board for noise-prevention purposes.

Since the FPC is soft, it is

difficult to keep it flat.

●

Typical transfer jigs for the board

mounting process

- Magic resin (Daisho Denshi)

- Keiju board (Mitsubishi Resin)

- Assist carrier (ShinEtsu Polymer)

To keep the FPC board flat during

mounting, we recommend the use of a

“Sticky transfer jig” for the wiring board

mounting process.

Workpiece

(FPC board, etc.)

Elastomer

(Weak adhesive layer)

Elastomer

(Strong adhesive layer)

Substrate

Workpiece (FPC, etc.)

Assist carrier

Layout pin

STEP 1:

Provisional fixing of workpiece

STEP 2:

Mounting complete

STEP 3:

Removal of

workpiece

Removal pin