MAINTENANCE / REPAIR

TROUBLESHOOTING

OPERATION

ASSEMBLY / INSTALLATION

SAFETY / SPECIFICATIONS

GETTING STARTED

6

ASSEMBLY / INSTALLATION (CONTINUED)

Power source

Running the unit on voltages which are not within the range may

cause over heating and motor burn-out. Heavy loads require that

the voltage at the motor terminals be no less than the voltage

specified.

Electrical connections

Make sure the tool is off before plugging it

into a power source to prevent accidental

starts.

Do not permit fingers to touch the

terminals of plug when installing or

removing from outlet.

Electrical safety

• Double insulated tools are equipped with a polarizing three

pronged plug (one blade is wider than the other.) This plug

will fit in a polarized outlet only one way. If the plug does not

fit fully into the outlet, reverse the plug. If it still does not fit,

contact a qualified electrician to install a polarized outlet. Do

not change the plug in any way.

• Double insulation eliminates the need for the three wire

grounded power cord and grounded power supply system.

Before plugging in the tool, be certain the outlet voltage

supplied is within the voltage marked on the nameplate.

• Avoid body contact with grounded surfaces such as pipes,

radiators, ranges and refrigerators. There is an increased

risk of electric shock if your body is grounded. If operating

the power tool in damp locations is unavoidable, a Ground

Fault Circuit Interrupter must be used to supply the power to

your tool. Rubber soled footwear will further enhance your

personal safety.

4. Don’t expose this or any tools to rain or wet conditions. Water

entering a power tool will increase the risk of electric shock

5. Do not abuse the cord. Never use the cord to carry the tool

or pull the plug from an outlet. Keep cord away from heat,

oil, sharp edges or moving parts. Replace damaged cords

immediately. Damaged cords increase the risk of electric

shock.

Extension cords

• The use of an extension cord will cause some drop in voltage

and loss of power.

• Wires of the extension cord must be of sufficient size to carry

the current and maintain adequate voltage.

• Use the table to determine the minimum wire size (A.W.G)

extension cord.

• Use only 3-wire extension cords having 3-prong grounding

type plugs and 3-pole receptacles which accept the tool plug.

• If the extension cord is worn, cut or damaged in any way,

replace it immediately.

Extension length

Wire Size

A.W.G.

Up to 25 ft

16

25 to 100 ft

14

NOTE: Using extension cords over 100 ft long is not

recommended.

Locating the machine

The Model 9682905 Grinder / Sharpener Machine should

be mounted on a suitable bench or stand. For optimum

performance, it is recommended the supporting device and

machine be leveled.

• Make certain any supporting stands or benches can hold the

machine since it weighs over 100 lbs. It is recommended the

machine be moved with a suitable hoist, forklift or carefully

lifted by two people. Do not stand under the machine while it

is being lifted or suspended.

• Locate the machine where it is easy to remove the power

plug and is easily accessible for maintenance.

Inserting the tool carrier shaft tension knob

1. Locate the Tool Carrier Shaft Tension Knob from the supplied

items.

2. Insert the knob into the hole on the lower left front portion of

the tool and slightly tighten it.

3. The knob acts as a stop and limits the rotation of the tool

carrier shaft under tension.

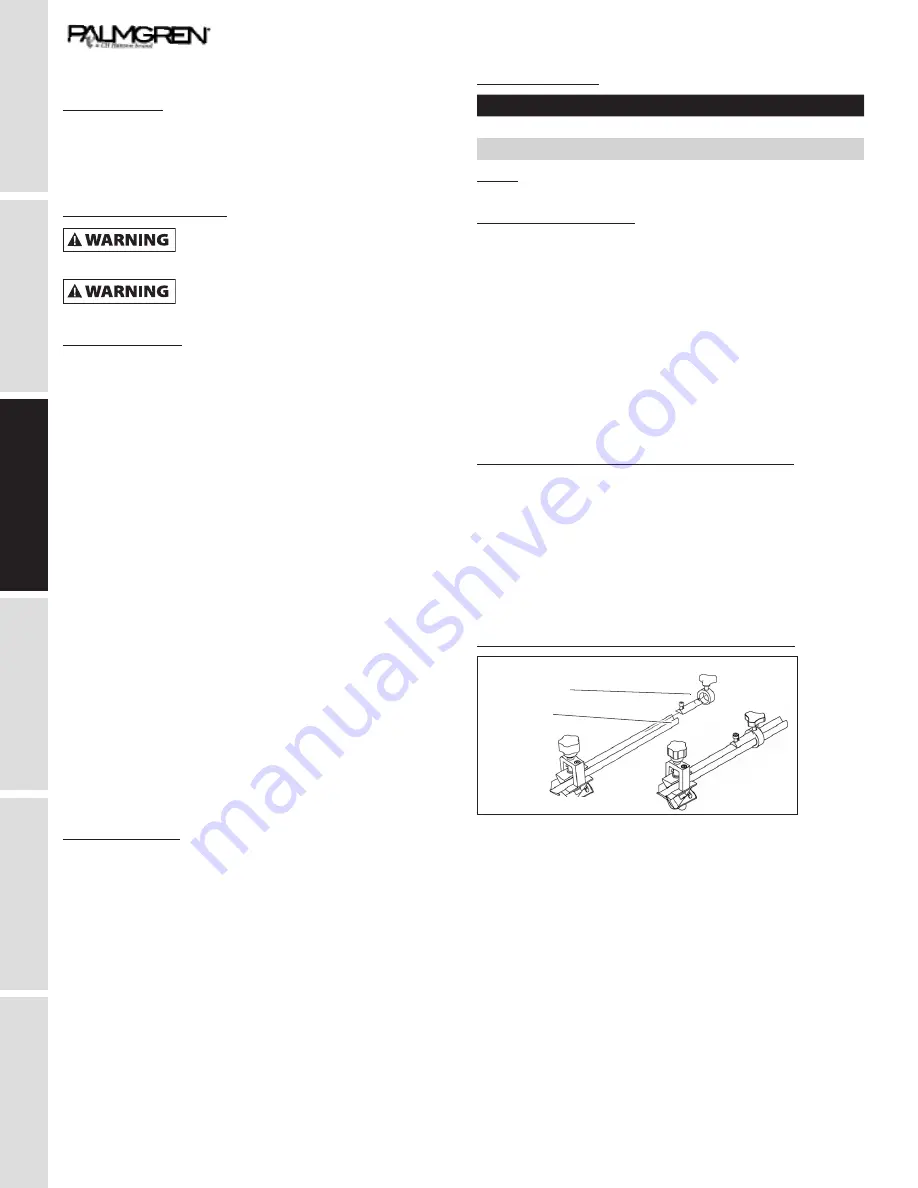

Assembling the drill bit clamping accessory

12

Clamping ring

Clamping

ece

Clamping Ring

Clamping

Piece

The Model 9682905 Grinding / Sharpener can sharpen v-blade

mill bits (burins), end mills, twist drill bits and lathe cutters with

the use of accessories that attach to the Grinder / Sharpener

machine. The Drill Bit Grinding Accessory requires minor

assembly before use.

1. Insert the clamping ring end into the Drill Bit Grinding

Accessory.

2 Tighten the small thumb screw to hold the ring into the

accessory.